Modified nano-silica sol containing rich hydrophilic groups and preparation method of modified nano-silica sol

A technology of nano-silica and hydrophilic groups, which is applied in the direction of coating, etc., can solve the problems of powder characteristics that are easy to bring in impurities, low production efficiency, wide particle size distribution, etc., and achieve simple and controllable preparation methods, reduce Effect of cost, good hydrophilicity and oleophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

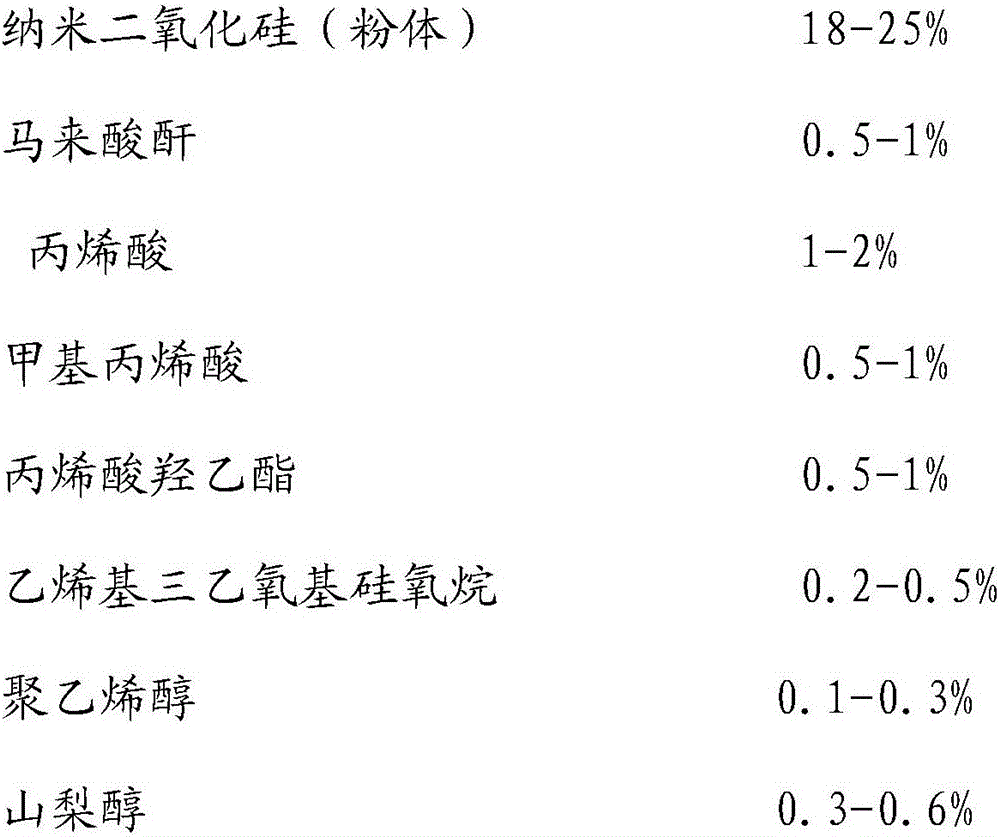

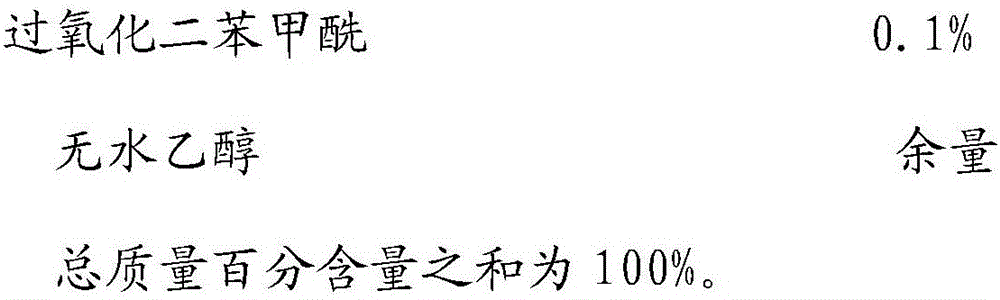

[0024] A modified nano-silica sol rich in hydrophilic groups, comprising the following raw materials:

[0025]

[0026] Its specific preparation steps of the nano-silica sol modified by rich hydrophilic groups are:

[0027] (1), weigh each raw material in proportion, then in a 250ml there-necked flask with a thermometer and a stirrer, add 18g of nano silicon dioxide and 78.8g of absolute ethanol, stir at 40°C for 10 minutes, then Add 0.2g of vinyltriethoxysiloxane and stir again for 30 minutes;

[0028] (2), then add 0.5g maleic anhydride, 1g acrylic acid, 0.5g methacrylic acid, 0.5g hydroxyethyl acrylate to the there-necked flask, stir thoroughly for 10 minutes, add 0.1g dibenzoyl peroxide, heat up to boiling;

[0029] (3) Boiling and reacting for 3 hours, keeping warm for 30 minutes, then adding polyvinyl alcohol and sorbitol, and stirring until completely dissolved. That is, the hydrophilic group-rich modified nano-silica alcohol sol is prepared.

Embodiment 2

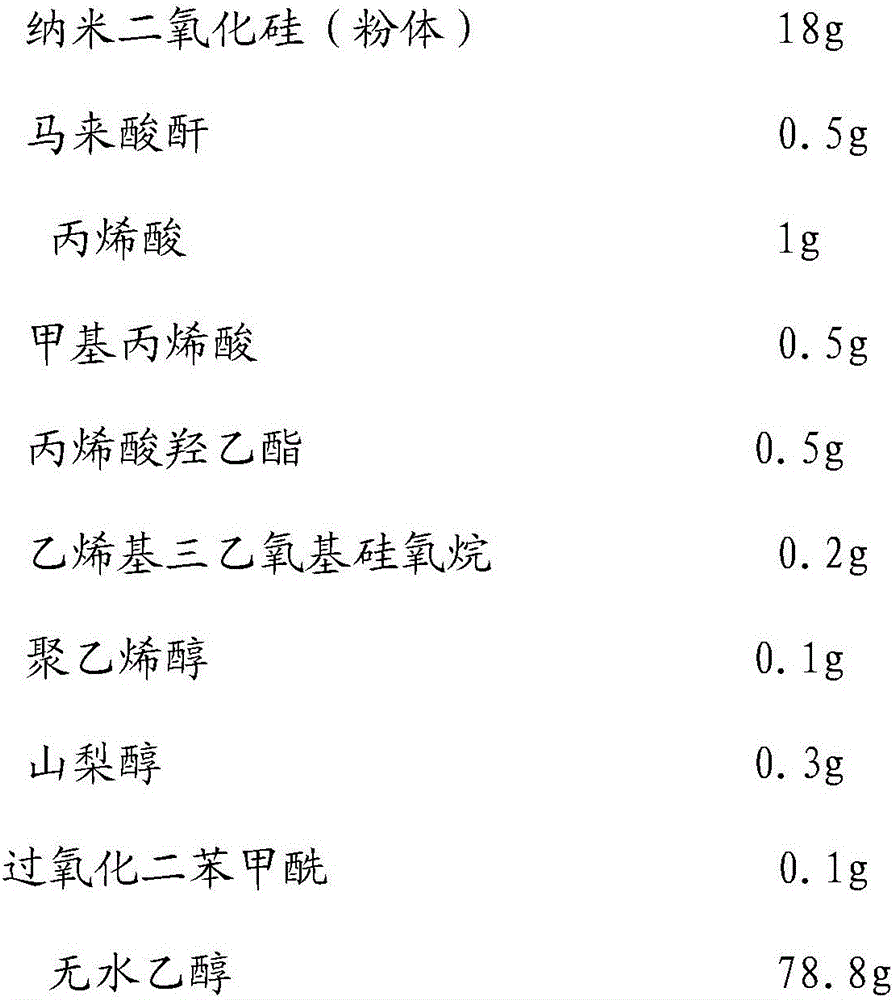

[0031] A modified nano-silica sol rich in hydrophilic groups, comprising the following raw materials:

[0032]

[0033]

[0034] The preparation method is the same as the steps in Example 1.

Embodiment 3

[0036] A modified nano-silica sol rich in hydrophilic groups, comprising the following raw materials:

[0037]

[0038] The preparation method is the same as the steps in Example 1.

[0039] In order to test the strength of its hydrophilicity, the superhydrophilic coating was prepared with the nano-silica sol modified by the rich hydrophilic group and other raw materials. In the comparative example, only the nano-silica sol modified by the rich hydrophilic group The silica sol raw material is replaced by conventional nano-silica sol, the addition amount remains unchanged, the composition and content of the remaining raw materials remain unchanged, the preparation method is the same, and then the water contact angle of the prepared coating is inspected, and the detection method is the same.

[0040] At room temperature, first add 20 g of nano-silica sol modified by rich hydrophilic groups, 0.5 g of polyvinyl alcohol solution, 1 g of sorbitan solution, 0.5 g of polyethylene g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com