Preparation method for synthesizing fluorescent polymer nanoparticles on basis of polyethyleneimine

A polyethyleneimine and fluorescent polymer technology, applied in the field of nanomaterials, can solve the problems of cumbersome synthesis process, poor environmental protection and high cost, and achieve the effects of excellent fluorescence performance, strong stability and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1.1 Weigh 0.7046g of polyethyleneimine (molecular weight: 600) into a 4mL plastic centrifuge tube, add 2mL of ultrapure water into it, shake and mix evenly to prepare A solution;

[0034] 1.2 Weigh 0.3523g of ascorbic acid into a 4mL plastic centrifuge tube, add 2mL of ultrapure water into it, shake and mix evenly to prepare B solution;

[0035] 1.3 Take 100 μL of solution B, add 50 μL of solution A to it, and then add 350 μL of ultrapure water, shake and mix evenly to obtain a fluorescent polymer nanoparticle solution;

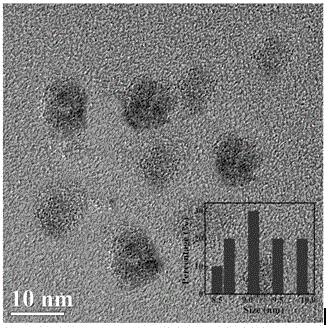

[0036] The particle size of the fluorescent polymer nanoparticles prepared in this example is 9.1 nm, and it takes 14 days to stabilize, and the stable period is at least 3 months.

Embodiment 2

[0038] 2.1 Weigh 0.7046g polyethyleneimine (molecular weight: 1300) into a 4mL plastic centrifuge tube, add 2mL ultrapure water to it, shake and mix evenly to prepare A solution;

[0039] 2.2 Weigh 0.3523g of ascorbic acid into a 4mL plastic centrifuge tube, add 2mL of ultrapure water into it, shake and mix evenly to prepare B solution;

[0040] 2.3 Take 100 μL of solution B, add 100 μL of solution A to it, and then add 300 μL of ultrapure water, shake and mix evenly to obtain a fluorescent polymer nanoparticle solution;

[0041] The particle size of the fluorescent polymer nanoparticles prepared in this example is 9.2 nm, and it takes 13 days to stabilize, and the stable period is at least 3 months.

Embodiment 3

[0043] 3.1 Weigh 0.7046g polyethyleneimine (molecular weight: 1800) into a 4mL plastic centrifuge tube, add 2mL ultrapure water into it, shake and mix evenly to prepare A solution;

[0044] 3.2 Weigh 0.3523g of ascorbic acid into a 4mL plastic centrifuge tube, add 2mL of ultrapure water into it, shake and mix evenly to prepare B solution;

[0045] 3.3 Take 100 μL of solution B, add 150 μL of solution A to it, and then add 250 μL of ultrapure water, shake and mix evenly to obtain the fluorescent polymer nanoparticle solution;

[0046] The particle size of the fluorescent polymer nanoparticles prepared in this example is 9.2 nm, and it takes 13 days to stabilize, and the stable period is at least 3 months.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com