Cellulose/graphene oxide composite film and preparing method thereof

A graphene composite and cellulose technology, applied in the field of composite materials, can solve problems such as difficulty in obtaining thin films with smooth surfaces, difficulty in regulation, and impact on bacterial cellulose production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

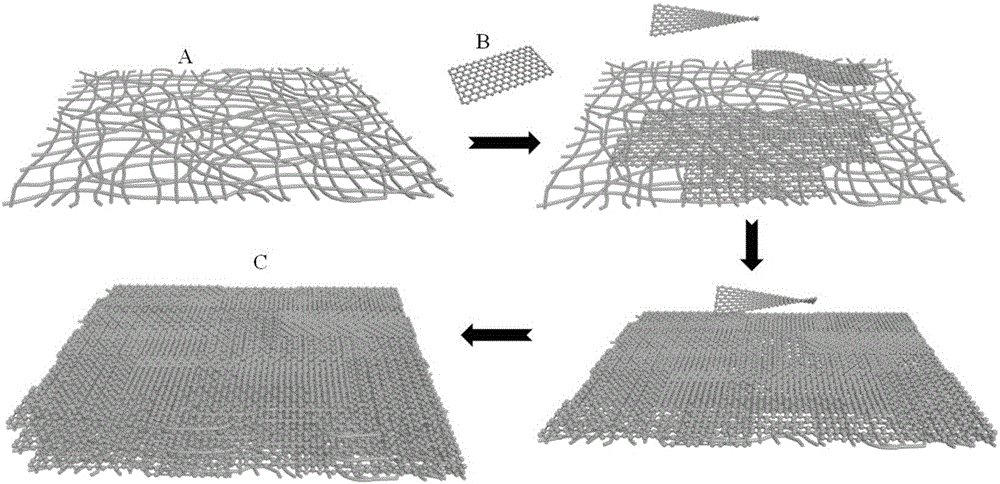

[0037] The present invention also provides a method for preparing the above-mentioned cellulose / graphene oxide composite film, comprising the following steps: S1) dispersing the cellulose airgel in an amide solvent to obtain a mixed solution; S2) dispersing the mixed solution Mix with graphene oxide aqueous solution, and vacuum filter to obtain cellulose / graphene oxide composite membrane.

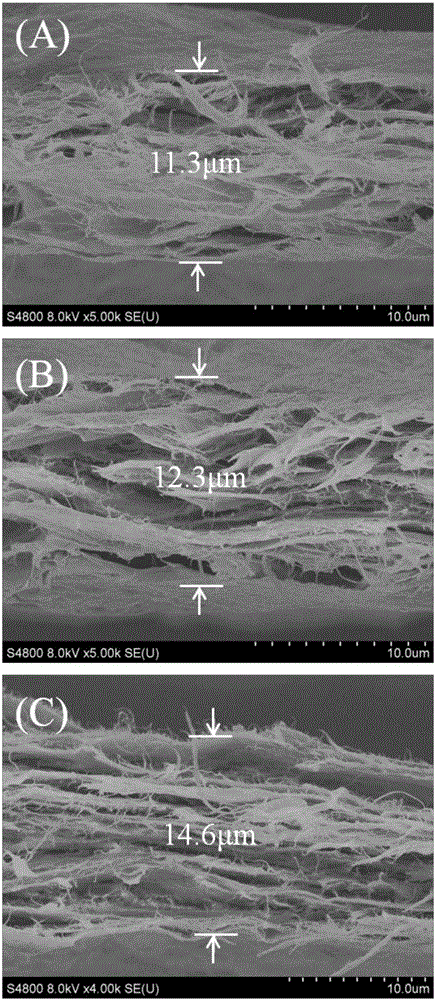

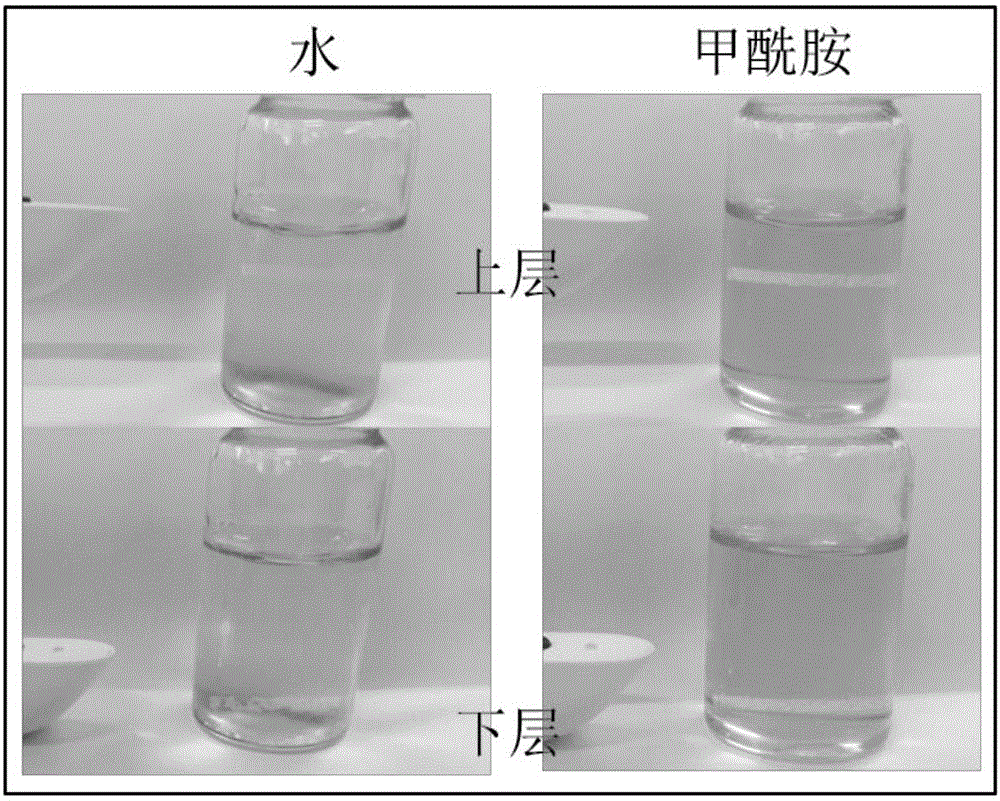

[0038] In the present invention, the amide solvent is used as a solvent to break and dissolve the cellulose airgel network structure to obtain a smaller cellulose micro-network structure. Many cellulose microstructures are pressed into a two-dimensional planar network, which is used as a supporting framework for the deposition of graphene oxide nanosheets. After multi-layer assembly, a cellulose / graphene oxide composite film with high mechanical strength is obtained, and the preparation method realizes A high degree of microcomposite between cellulose and graphene oxide was achieved.

[00...

Embodiment 1

[0051] 1.1 Purification and dissolution of bacterial cellulose (BC):

[0052] BC purification: soak the BC hydrogel membrane in 2% (w / v) NaOH aqueous solution, heat treatment at 60°C for 24h; then wash it with deionized water until neutral.

[0053] BC airgel: The purified BC hydrogel film is crushed by physical machinery, and freeze-dried to remove water to obtain BC airgel.

[0054] BC dissolution: 50 mg of BC airgel was added to 50 ml of formamide solution, and the ultrasonic cell disruptor (at 400 W power) was used to sonicate for 2 hours to fully disperse BC in the formamide solution to prepare a 1 mg / ml mixed solution.

[0055] 1.2 Preparation of graphene oxide (GO) (using the improved Hummers method):

[0056] Graphite pre-oxidation: 9g flake graphite (80μm) and 7.5gK 2 S 2 o 8 , 7.5gP 2 o 5 , 36ml concentrated H 2 SO 4 Magnetically stir in a water bath at 80°C for 4 hours; then slowly add 750ml of deionized water; filter and wash with deionized water 2 to 3 tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com