Preparation method for antioxidant gasoline engine lubricating oil

A gasoline engine and lubricating oil technology, applied in the field of lubricating oil, can solve the problems of high cost and poor oxidation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

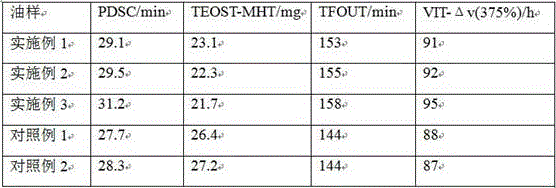

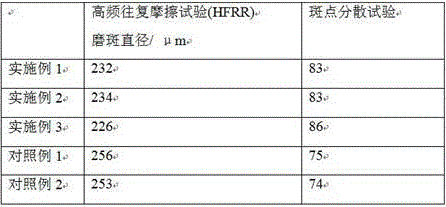

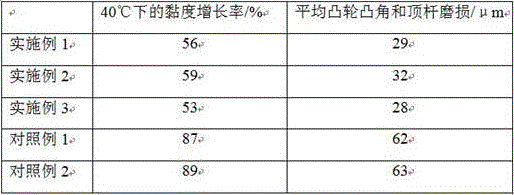

Examples

Embodiment 1

[0030] The first step, the modification of rapeseed oil: by weight, get 50 parts of rapeseed oil, 3 parts of diethanolamine, 3 parts of toluene and mix evenly, then dropwise add 1 part of concentrated sulfuric acid, then add 10 parts of toluene, in nitrogen Under protection, the temperature was raised to 130°C for 1 hour. After the reaction, the temperature was lowered to 110°C, 2 parts of boric acid was added, and the temperature was kept for 1 hour. After the end, it was washed with 5wt% NaOH aqueous solution to neutrality, and it was distilled under reduced pressure at 65°C. Steam out toluene to obtain modified rapeseed oil;

[0031] Step 2, in parts by weight, mix 30 parts of mannitol, 20 parts of oxalic acid, 20 parts of oleanolic acid, 3 parts of catalyst, and 80 parts of organic solvent, and then heat up to 70°C for 2 hours of reaction , steaming off the organic solvent to obtain polyol ester;

[0032] In the third step, by weight, 100 parts of the second-class hydroge...

Embodiment 2

[0034]The first step, the modification of rapeseed oil: by weight, get 60 parts of rapeseed oil, 5 parts of diethanolamine, 4 parts of toluene and mix evenly, then dropwise add 3 parts of concentrated sulfuric acid, then add 15 parts of toluene, in nitrogen Under protection, the temperature was raised to 150 ° C for 4 hours. After the reaction, the temperature was lowered to 120 ° C, and 3 parts of boric acid were added, and then kept for 3 hours. Steam out toluene to obtain modified rapeseed oil;

[0035] Step 2, in parts by weight, mix 40 parts of mannitol, 30 parts of oxalic acid, 30 parts of oleanolic acid, 5 parts of catalyst, and 120 parts of organic solvent, and then heat up to 90°C for 4 hours of reaction , steaming off the organic solvent to obtain polyol ester;

[0036] In the 3rd step, by weight, 120 parts of the second-class hydrogenated base oil 500N, 25 parts of modified rapeseed oil, 7 parts of polyol ester, 0.08 part of molybdenum dialkyl dithiocarbamate, anti...

Embodiment 3

[0038] The first step, the modification of rapeseed oil: by weight, get 55 parts of rapeseed oil, 4 parts of diethanolamine, 4 parts of toluene and mix evenly, then dropwise add 2 parts of concentrated sulfuric acid, then add 12 parts of toluene, in nitrogen Under protection, the temperature was raised to 140°C for 3 hours. After the reaction, the temperature was lowered to 114°C, 2 parts of boric acid was added, and the temperature was kept for 2 hours. After the end, it was washed with 5wt% NaOH aqueous solution to neutrality, and it was distilled under reduced pressure at 65°C. Steam out toluene to obtain modified rapeseed oil;

[0039] Step 2, in parts by weight, mix 34 parts of mannitol, 25 parts of oxalic acid, 25 parts of oleanolic acid, 4 parts of catalyst, and 110 parts of organic solvent, and then heat up to 80°C for 3 hours of reaction , steaming off the organic solvent to obtain polyol ester;

[0040] In the 3rd step, by weight, 120 parts of the second-class hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com