Graphene/ metal nanometer wire grid composite transparent conductive electrode and application

A technology of transparent conductive electrodes and metal nanowires, used in cable/conductor manufacturing, conductive layers on insulating carriers, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

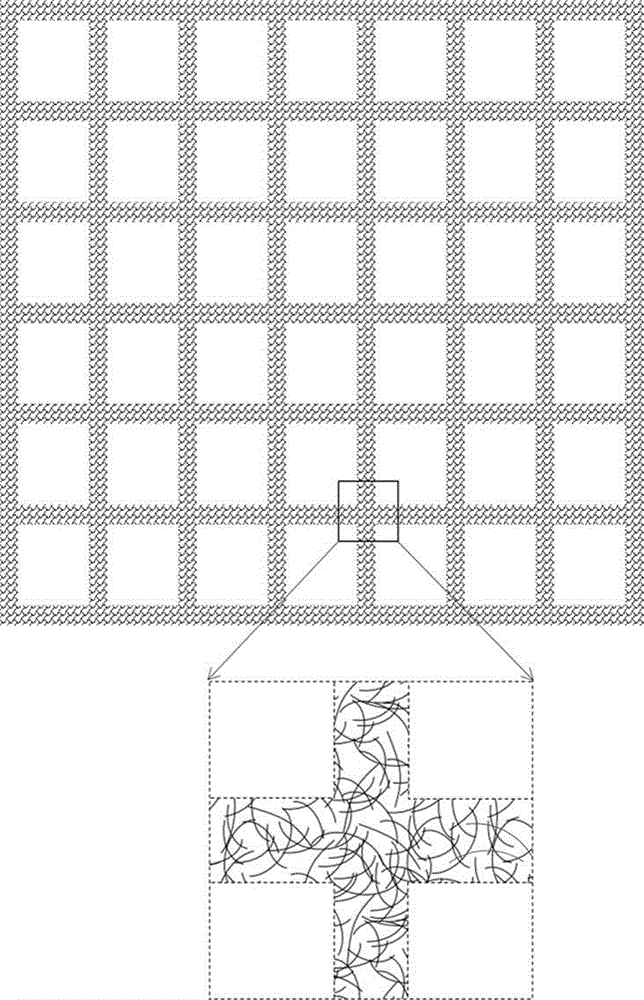

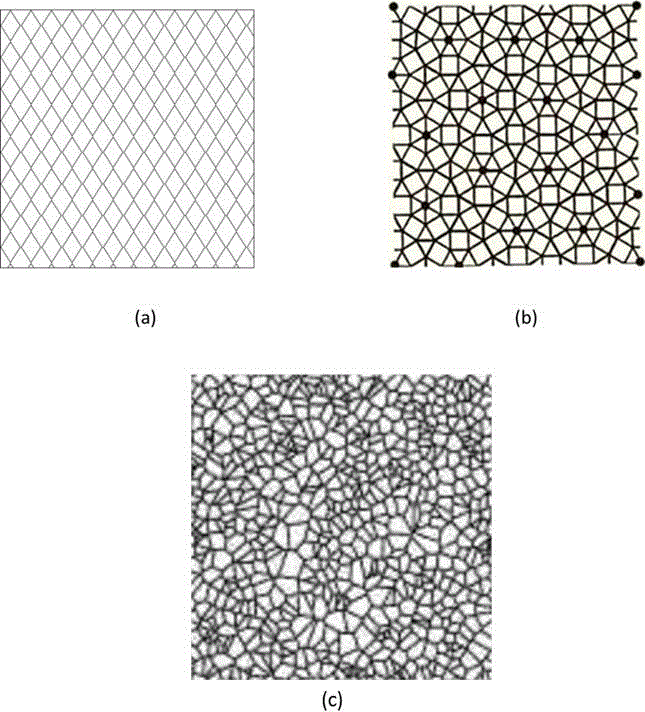

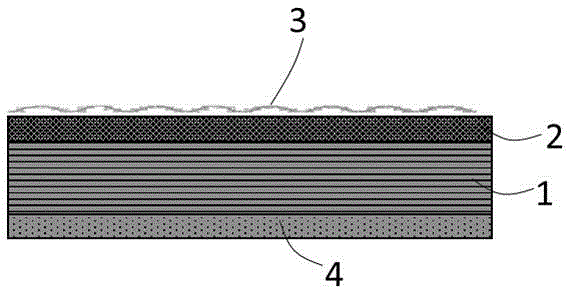

Method used

Image

Examples

preparation example 1

[0063] Preparation Example 1: Preparation of silver nano screen printing ink

[0064] The synthesis of silver nanowires refers to the literature "The effect of nanowire length and diameter on the properties of transparent, conducting nanowire films, Nanoscale, 2012, 4, 1996". Four silver nanowires with different diameters and lengths were prepared.

[0065]

[0066] The synthesized silver nanowires were dispersed in a solvent with a mass fraction of 2:5 n-hexanol and n-butanol, and then hydroxypropyl methylcellulose and fluorocarbon surfactant were added to adjust the rheological parameters. In the final ink, the mass fraction of silver nanowires was 1%, the mass fraction of hydroxypropyl methylcellulose was 5%, and the mass fraction of fluorocarbon surfactant was 0.005%.

preparation example 2

[0067] Preparation Example 2: Preparation of Graphene Coating Solution

[0068] Thermally expandable graphite powder or microcrystalline graphite or natural graphite (1 part quality) is joined in the N-methylpyrrolidone solvent (2000 parts), ultrasonic 45min in the supersonic instrument of 300w power, use the dispersion liquid that obtains at 500 Centrifuge for 60 min at a speed of rpm to discard the thick graphite sheet at the bottom to obtain a gray sol in the upper layer. The gray sol in the upper layer is centrifuged at a speed of 5000 rpm, and a black graphene sol is obtained at the bottom, which is used to prepare a graphene-containing film. The obtained sol was prepared as a dispersion liquid with a concentration of 0.5 mg / ml, and the solvent of the dispersion liquid was N-methylpyrrolidone.

preparation example 3

[0069] Preparation Example 3: Preparation of Graphene Oxide Coating Solution

[0070] Treat natural graphite powder (2 parts by mass), concentrated sulfuric acid (90 parts by mass) and potassium permanganate (10 parts by mass) under ice bath conditions for 3 hours, raise the temperature to about 35°C, keep it for 30 minutes, and slowly add 100 parts Quality water, keep the temperature at about 95°C, add 40 parts by weight of water within 45 minutes, then add 10 parts by weight of 30% hydrogen peroxide and 100 parts by weight of water to obtain a bright yellow suspension. The suspension was filtered, the filter cake was washed 3 times with hydrochloric acid with a mass fraction of 5% by weight, and the obtained filter cake was dried at 60° C., and the obtained filter cake was dispersed in water to obtain a graphene oxide sol, which was centrifuged and separated. Re-disperse, after multiple treatments (generally more than 3 times) to obtain a relatively pure graphene oxide sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com