Preparation method of Rh nanoflower electrocatalyst for alkaline direct methanol fuel cell

A methanol fuel cell and catalyst technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of dependence, achieve high active sites, excellent electrocatalytic activity, and suppress the effect of Ostwalder ripening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

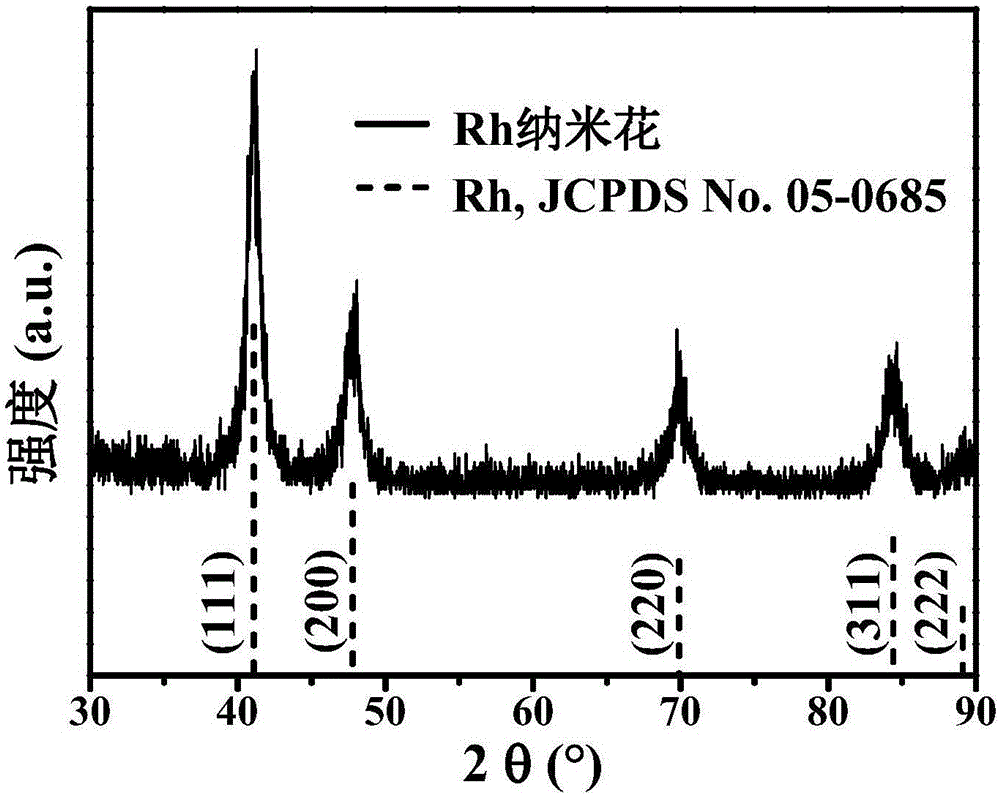

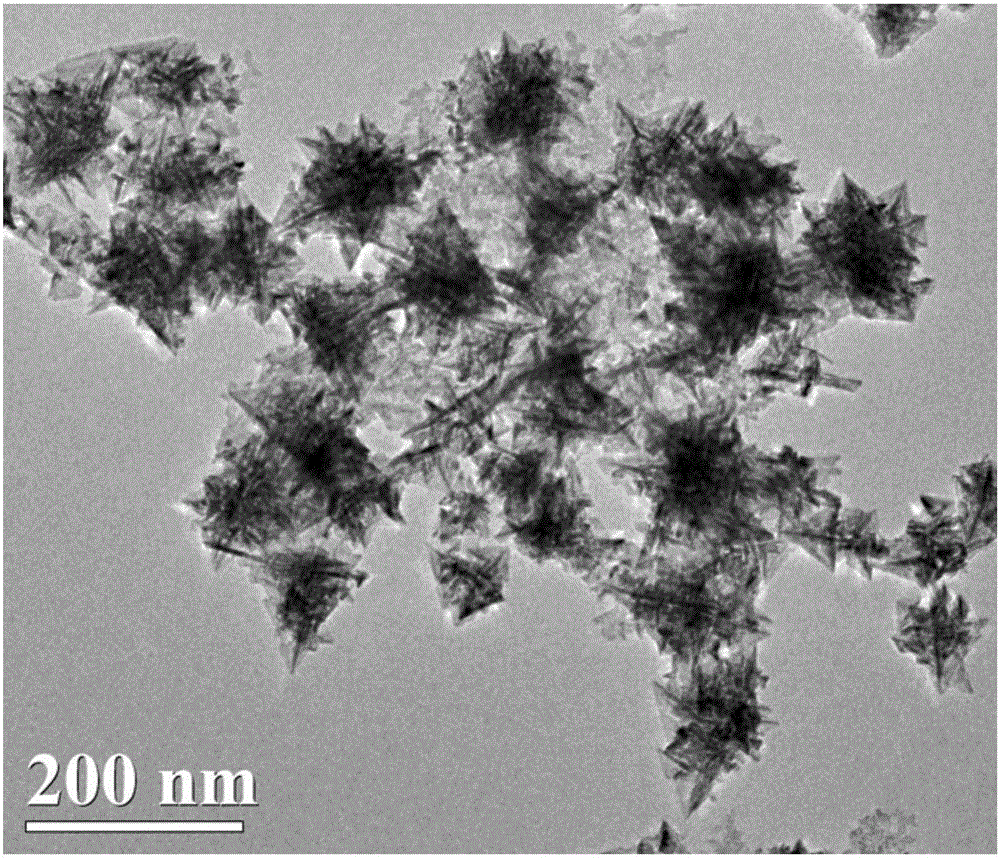

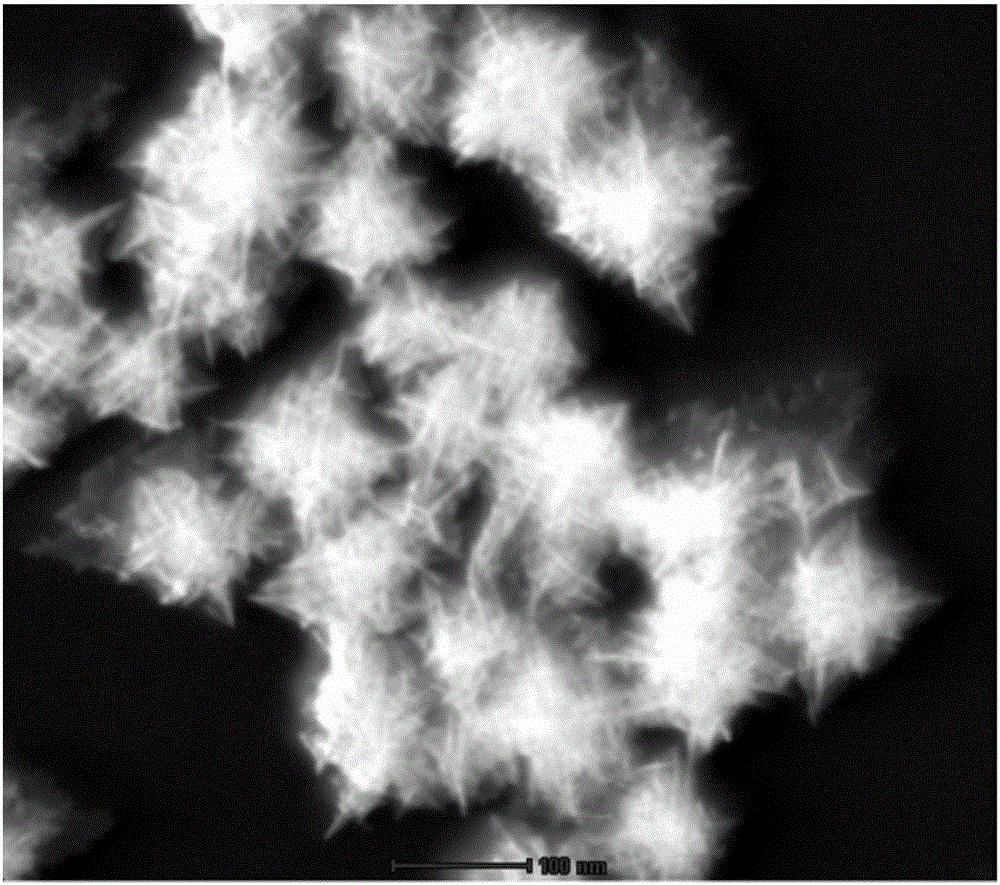

[0021] 0.5mL0.1mol / L of RhCl 3 Aqueous solution, 0.5mL 0.5mol / L PEI aqueous solution with a number average molecular weight of 10000 was added to a 10mL beaker, mixed evenly, under stirring conditions, the resulting mixed solution was adjusted to pH 3 with 1mol / L HCl aqueous solution, and then 0.5mL (5.25mmol) diethylene glycol, where RhCl 3 The molar ratio with PEI and diethylene glycol is 1:5:105, and then transferred to the reaction kettle, and the reaction kettle was placed in an oven at 180°C for a closed reaction for 10 hours, cooled to room temperature, centrifuged, and washed with distilled water for 3~ 5 times, and dried in a vacuum oven at 60°C to obtain the Rh nanoflower electrocatalyst. Depend on figure 1 It can be seen that the four diffraction peaks are located at 41.068, 47.780, 69.877 and 84.393°, which are consistent with the standard card of the face-centered cubic (FCC) Rh crystal (JCPDS No. 05-0685) and no additional diffraction peaks are observed, indica...

Embodiment 2

[0024] 0.5mL0.1mol / L of RhCl 3 Aqueous solution, 0.5mL 0.5mol / L PEI aqueous solution with a number average molecular weight of 8000 was added to a 10mL beaker, mixed evenly, under stirring conditions, the resulting mixed solution was adjusted to pH 4 with 1mol / L aqueous HCl solution, and then 0.475mL was added (5mmol) diethylene glycol, where RhCl 3 The molar ratio of PEI and diethylene glycol is 1:5:100, and then transferred to the reactor, and the reactor was placed in an oven at 200°C for a closed reaction for 8 hours, cooled to room temperature, centrifuged, and washed with distilled water for 3~ 5 times, dried in a vacuum oven at 60°C to obtain the Rh nanoflower electrocatalyst (see Figure 7-8 ).

Embodiment 3

[0026] 0.5mL0.1mol / L of RhCl 3 Aqueous solution, 0.5mL 0.5mol / L PEI aqueous solution with a number average molecular weight of 12000 was added to a 10mL beaker, mixed evenly, under stirring conditions, the resulting mixed solution was adjusted to pH 2 with 1mol / L aqueous HCl solution, and then 0.525mL was added (5.5mmol) diethylene glycol, where RhCl 3 The molar ratio of PEI and diethylene glycol is 1:5:110, and then transferred to the reaction kettle, and the reaction kettle was placed in an oven at 160°C for a closed reaction for 12 hours, cooled to room temperature, centrifuged, and washed with distilled water for 3~ 5 times, dried in a vacuum oven at 60°C to obtain the Rh nanoflower electrocatalyst (see Figure 9-10 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com