Composite protein surfactant foaming agent

The technology of surfactant and protein is applied in the field of protein-surfactant compound foaming agent, which can solve the problems of poor performance of single-component foaming agent, incapability of large-scale use, complicated foaming agent preparation process, etc. To achieve the effect of strong foam stabilization, large foam volume, and improved interaction

Active Publication Date: 2016-08-03

SHAANXI NORMAL UNIV

View PDF8 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the mainstream foaming agent on the market is the fourth generation composite foaming agent, which solves the problem of poor performance of single-component foaming agents

For example, the Chinese patent whose publication number is CN103553421B and whose invention name is "An Environmentally Friendly Compound Concrete Foaming Agent and Its Preparation Method" discloses a compound consisting of alkyl glucoside, sodium fatty acid methyl ester sulfonate, cocamidopropyl Concrete foaming agent composed of betaine, tea saponin, gum arabic, polyethylene glycol and bentonite. This foaming agent has good foaming ability, fine and uniform foam, and less bleeding, but the composition of this foaming agent is complex. , the cost is high, and it cannot be used on a large scale

The Chinese patent whose publication number is CN102964083B and whose invention name is "A Modified Soybean Protein Concrete Foaming Agent" discloses that the modified soybean powder, cetyltrimethylammonium bromide, sodium dodecylbenzenesulfonate , rhamnolipid, gum arabic and hydrogen peroxide, the foaming agent has the characteristics of good concrete compatibility and high air bubble rate, but the preparation process of this foaming agent is relatively complicated and has many components , and the cost is relatively high

The Chinese patent whose publication number is CN102765962A and whose invention name is "A Foaming Agent for Polymer Concrete and Its Preparation Method" discloses a kind of foaming agent composed of macromer, sodium sulfite, acetone, formaldehyde, sodium methallyl sulfonate and Composite foaming agent composed of water, this foaming agent has the characteristics of stable product, good water solubility, and not easy to deteriorate, but the materials used in this foaming agent will pollute the environment and be toxic, and its application range is very limited

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0017] Mix 0.20 g sodium caseinate and 0.40 g sodium lauryl glycinate evenly to obtain a composite foaming agent.

Embodiment 2

[0019] Mix 0.30 g sodium caseinate and 0.30 g sodium lauryl glycinate evenly to obtain a composite foaming agent.

Embodiment 3

[0021] Mix 0.36g sodium caseinate and 0.24g sodium lauryl glycinate evenly to obtain a composite foaming agent.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Login to View More

Abstract

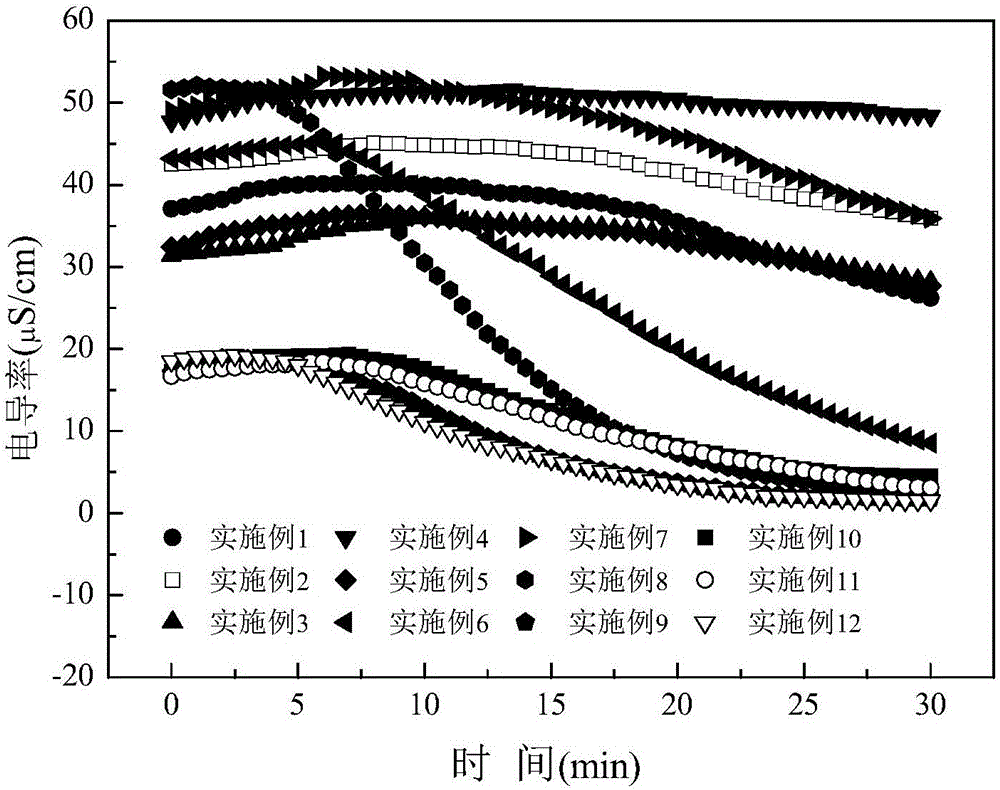

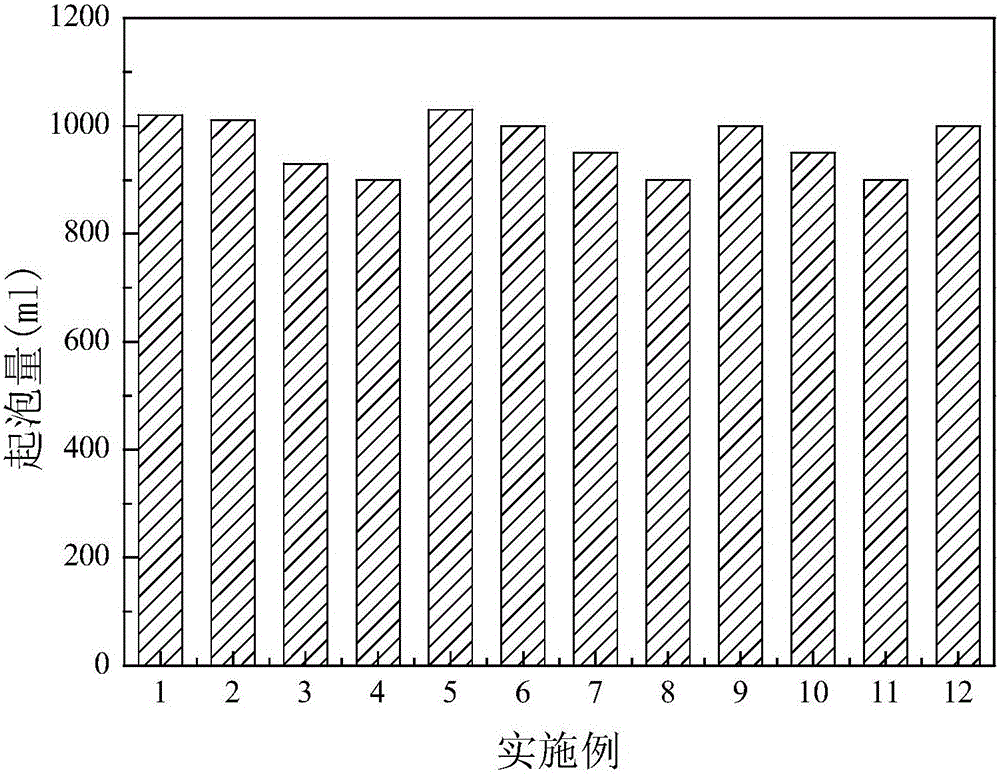

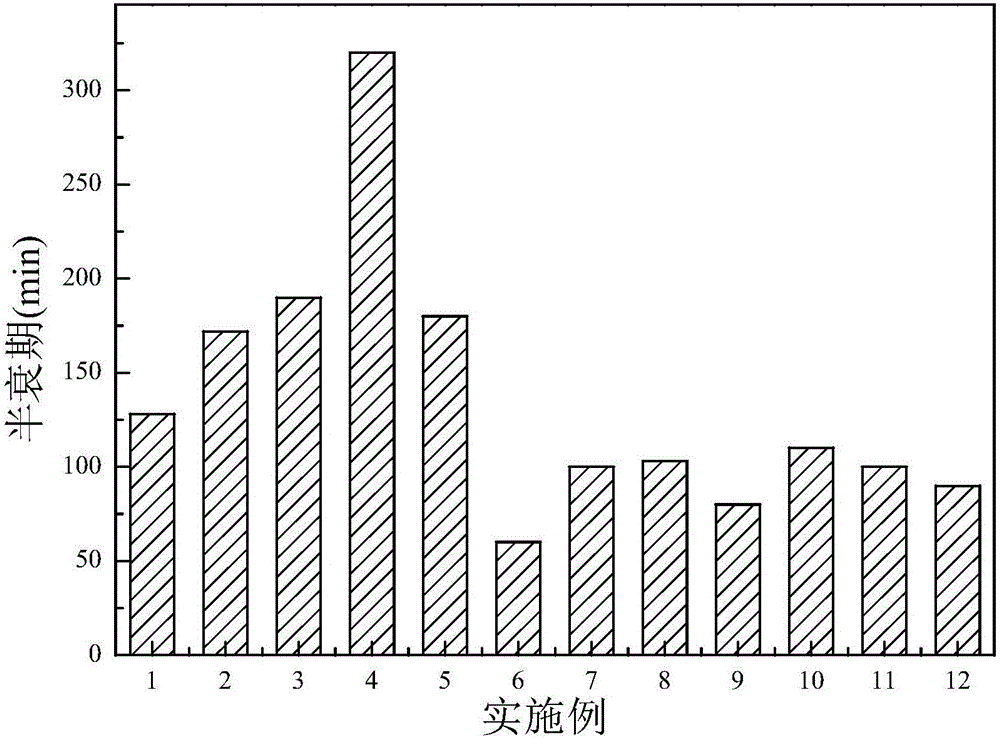

The invention discloses a composite protein surfactant foaming agent. The foaming agent is prepared by mixing an anionic surfactant or an ampholytic surfactant with a protein anionic surfactant according to the mass ratio of 1:(0.5-3), wherein sodium caseinate is adopted as the protein anionic surfactant, lauryl sodium sulfate or lauryl sodium glycinate or sodium lauryl sarcosinate is adopted as the anionic surfactant, and lauramidopropylamine oxide or cocamidopropyl dimethylamine oxide is adopted as the ampholytic surfactant. According to the composite protein surfactant foaming agent, through the synergistic effect among the different types of surfactants, the surface tension of the system solution is reduced, the water carrying capacity of a film is improved, the thickness of the foam film is increased, and therefore the foam strength is improved. The foaming agent has the advantages that few components are contained, the using amount is little, no other auxiliary needs to be added, foaming is rapid, the foaming amount is large, the stability is very good, and the compatibility with concrete grout is good.

Description

technical field [0001] The invention belongs to the technical field of fine chemicals and light inorganic materials, and in particular relates to a protein surfactant composite foaming agent. Background technique [0002] At present, there are two main technologies for preparing foamed concrete. One is chemical foaming, that is, during the mixing process of concrete slurry, the method of releasing gas through a chemical reaction causes pores inside the concrete to be prepared into foamed concrete; the other is Physical foaming, that is, the foaming agent is prepared into foam by stirring or air blowing, and then mixed with concrete slurry to prepare foamed concrete. Compared with chemical foaming, the cost of physical foaming is low, and the process is relatively simple. Therefore, physical foaming is the main method in the preparation process of foamed concrete. Surfactant composite foaming agent is the most widely used foaming agent in physical foaming. On the one hand, a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B24/14C04B24/16C04B103/40

CPCC04B40/0039C04B2103/40C04B2103/402C04B24/14C04B24/123C04B24/16C04B24/121

Inventor 陈亚芍张峰杨杰韩莉君员乐

Owner SHAANXI NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com