Flame-retardant heat-conducting nylon and preparation method thereof

A technology of nylon and flame retardant, which is applied in the field of polymer synthesis modification and processing, which can solve the problems of high heat dissipation effect of thermally conductive nylon, and achieve the effect of improving heat dissipation, improving charge conduction, and improving energy exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

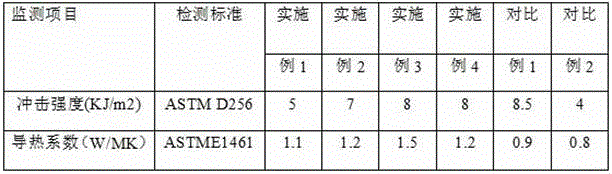

Examples

Embodiment 1

[0037] S1. Add 35kg of thermally conductive filler magnesium oxide, 12kg of negative ion powder, 1kg of coupling agent KH550, and 1kg of lubricant PETS into the high-mixer, and mix at a high speed of 1400 rpm and a temperature of 80°C for 30 minutes;

[0038] S2. Add 30kg of nylon 6, 10kg of antistatic resin PebaxMV1074, 10kg of a compound of decabromodiphenylethane and antimony oxide with a mass ratio of 4:1, and a compound of antioxidant 1076 and 168 with a mass ratio of 1:2 Continue to mix at a high speed of 1400 rpm and a temperature of 110°C for 10 minutes;

[0039] S3. Pelletizing the above mixture through a twin-screw extruder at a temperature of 230-290° C. and a rotation speed of 800 rpm to obtain a modified flame-retardant and heat-conducting nylon.

Embodiment 2

[0041] S1. Add 10kg of thermally conductive filler alumina, 15kg of thermally conductive filler boron carbide, 12kg of negative ion powder, 1kg of coupling agent KH550, and 1kg of amide wax into the high-mixer, and mix at a high speed of 800 rpm and a temperature of 100°C for 60 minutes;

[0042] S2. Add 25kg of nylon 66, 15kg of antistatic resin PebaxMH2202, 20kg of magnesium hydroxide, 1kg of a compound of antioxidant 1076 and 168 with a mass ratio of 1:2, and continue to mix at a high speed at a speed of 800 rpm and a temperature of 100°C 10min,

[0043] S3. Pelletizing the above mixture through a twin-screw extruder at a temperature of 270-290° C. and a rotation speed of 200 rpm to obtain a modified flame-retardant and heat-conducting nylon.

Embodiment 3

[0045] S1. Add 20kg of thermally conductive filler alumina, 12kg of thermally conductive filler magnesia, 15kg of negative ion powder, 1kg of coupling agent KH560, and 1kg of amide wax into the high-mixer, and mix at a high speed of 1000 rpm and a temperature of 110°C for 30 minutes;

[0046] S2. Add 20kg nylon 6T, 5kg nylon 46, 15kg antistatic resin PebaxMH165, 10kg mass ratio of 4:1 decabromodiphenylethane and antimony oxide compound, 1kg mass ratio of 1:2 antioxidant 1076 For the compound with 168, continue to mix at high speed for 30 minutes at a speed of 1000 rpm and a temperature of 110°C;

[0047] S3. Pelletizing the above mixture through a twin-screw extruder at a temperature of 300-350° C. and a rotation speed of 500 rpm to obtain a modified flame-retardant and heat-conducting nylon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com