Preparation method and application of water-based silicon dioxide aerogel reflective heat insulation coating

A reflective heat-insulating coating, water-based silica technology, applied in the direction of reflection/signal coatings, coatings, etc., can solve the problems of long curing time, large thickness, large amount of glass beads or floating beads, etc., to achieve the preparation method The effect of simplicity, less economic investment, and high environmental returns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

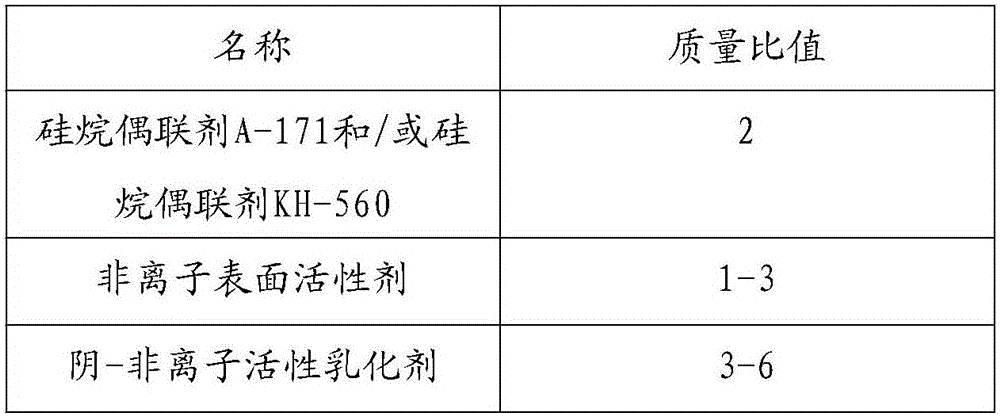

[0014] According to the above-mentioned preparation method, further, comprising: utilize silane coupling agent A-171 and / or silane coupling agent KH-560, nonionic surfactant, anion-nonionic active emulsifier to hydrophobic at 20-80 ℃ modify the surface of the silica airgel for 1-3 hours to obtain a modified airgel that is initially soluble in water; then add water-soluble polymer polyvinyl alcohol-2000 to the above-mentioned modified airgel that is initially soluble in water In the gel, stir and mix at 30-50°C for 2 hours, use it to coat the modified airgel, add distilled water to the coated modified airgel, stir and mix at 25-40°C for 1 hour, The modified silica airgel aqueous solution with good compatibility with the water-based resin is obtained.

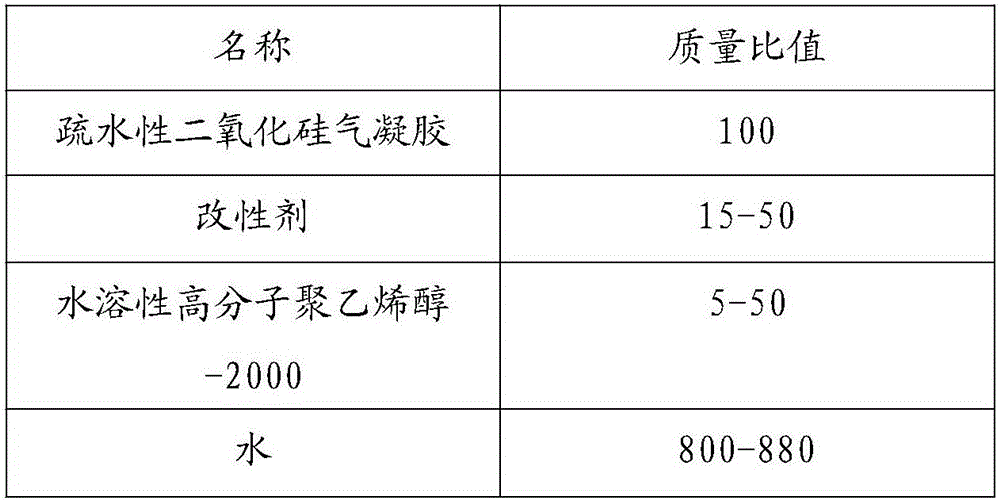

[0015] According to the above preparation method, further, the mass ratio of hydrophobic silica airgel, modifier, water-soluble polymer polyvinyl alcohol-2000 and water is shown in Table 1, and the silane coupling agent A in the ...

Embodiment 1

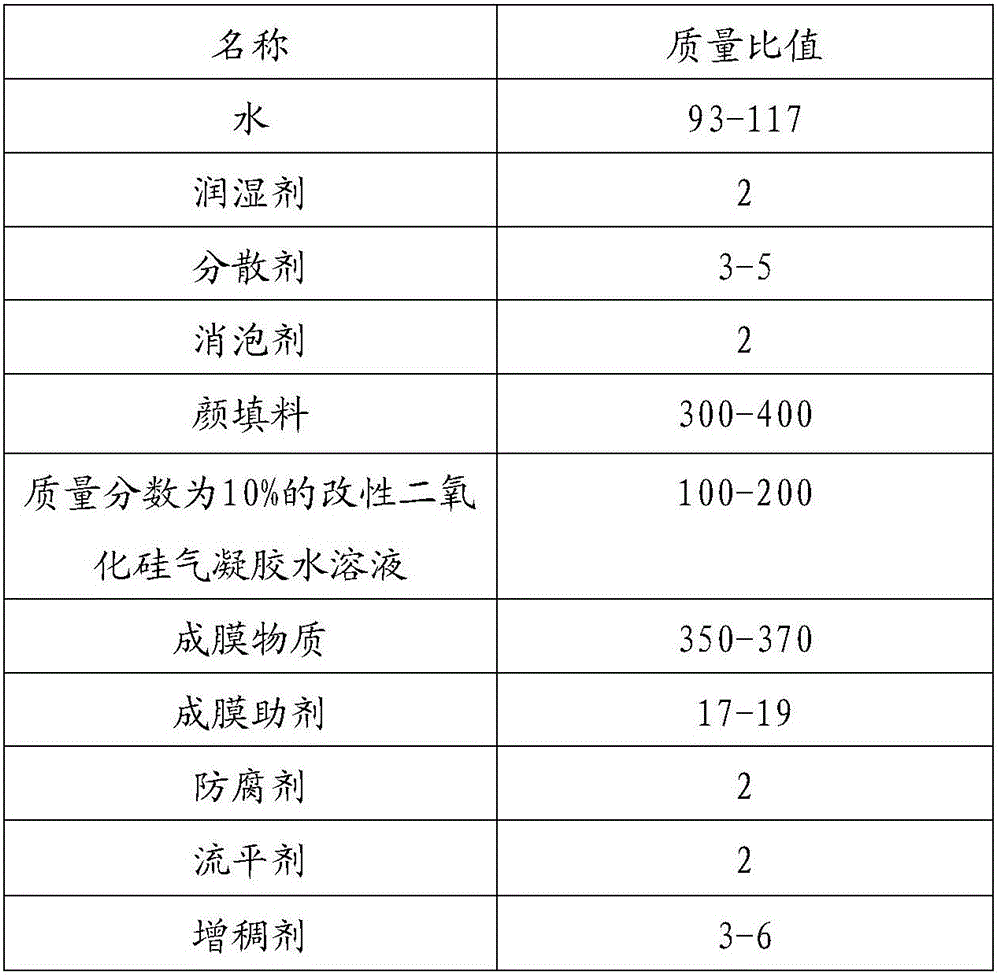

[0032] As shown in Table 4, a certain amount of water, wetting agent, dispersant, defoamer, pigment and filler, and a modified silica airgel aqueous solution with a mass fraction of 10% were weighed to obtain the particle size by high-speed dispersion and grinding. Slurries smaller than 40 μm. Add film-forming substances, film-forming aids, preservatives, and leveling agents in turn, stir evenly, and add thickener to adjust to a reasonable viscosity.

[0033] Table 4

[0034]

[0035] Take the above-mentioned paint, and apply the above-mentioned paint on the flat surface of building or metal materials under the condition that the construction temperature is higher than 5°C. After the surface is dry, apply the next layer until it is completely dry to obtain the water-based silica airgel reflective thermal insulation coating 1.

Embodiment 2

[0037] As shown in Table 5, weigh a certain amount of water, wetting agent, dispersant, defoamer, pigment and filler, and a modified silica airgel aqueous solution with a mass fraction of 10% to obtain the particle size by high-speed dispersion and grinding. Slurries smaller than 40 μm. Add film-forming substances, film-forming aids, preservatives, and leveling agents in turn, stir evenly, and add thickener to adjust to a reasonable viscosity.

[0038] table 5

[0039]

[0040] Take the above-mentioned paint, and apply the above-mentioned paint on the flat surface of building or metal materials under the condition that the construction temperature is higher than 5°C. After the surface is dry, apply the next layer until it is completely dry to obtain the water-based silica airgel reflective thermal insulation coating 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com