Sand inhibiting and antiswelling agent and preparation method thereof

A technology of anti-swelling agent and silane coupling agent, which is applied in the field of sand suppression and anti-swelling agent for oil-water well acidification and its preparation, and can solve the problems of poor synergy between anti-swelling agent and sand suppression agent, low anti-swelling rate and low sand suppression rate, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

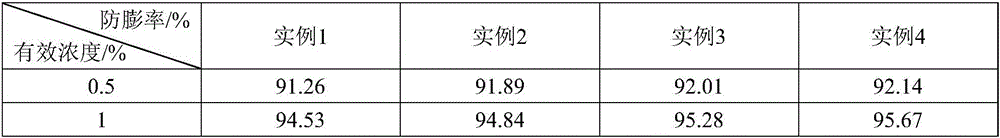

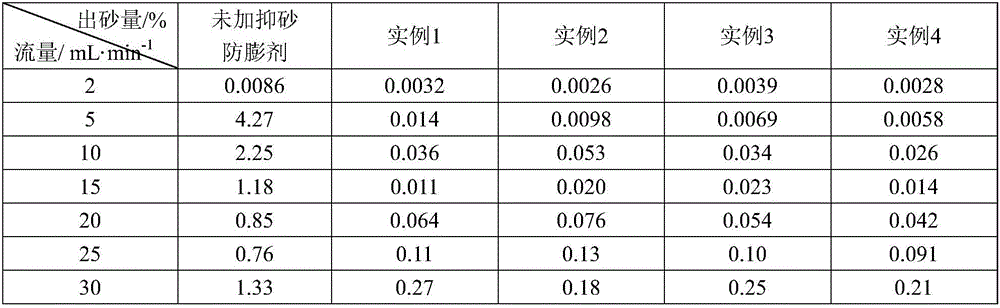

Embodiment 1

[0021] Example 1, weigh 23.32g of 1,2-ethylenediamine and add it into a four-neck flask. Turn on stir bar (medium speed) and condensed water. The water bath is filled with clear water to control the reaction temperature. Weigh 76.68g hydrochloric acid (effective content is 37%), join in the constant pressure funnel, control the opening degree of piston, make hydrochloric acid drip in the flask slowly. In this process, pay attention to controlling the rate of addition of hydrochloric acid not to be too fast, and ensure that the reaction temperature is always within 50°C. When the pH is between 5 and 6, stop the dropwise addition and continue the reaction for 0.5h. Then 2 g of a terpolymer of acrylamide, dimethyldiallylammonium chloride and 3-(methacryloyloxy)propyltrimethoxysilane are added. The temperature of the water bath was adjusted to 40° C., and the product was taken out after 6 hours of reaction to obtain a colorless viscous sand suppressing and anti-swelling agent p...

Embodiment 2

[0022] Example 2, weigh 30.85g of N,N-dimethylethylenediamine and add it into a four-neck flask. Turn on stir bar (medium speed) and condensed water. The water bath is filled with clear water to control the reaction temperature. Weigh 69.15g hydrochloric acid (effective content is 37%), join in the constant pressure funnel, control the opening degree of piston, make hydrochloric acid drip in the flask slowly. In this process, pay attention to controlling the rate of addition of hydrochloric acid not to be too fast, and ensure that the reaction temperature is always within 50°C. When the pH is between 5 and 6, stop the dropwise addition and continue the reaction for 0.5h. Then 2 g of a terpolymer of acrylamide, dimethyldiallylammonium chloride and vinyltrimethoxysilane are added. Adjust the temperature of the water bath to 45° C., and take out the product after reacting for 5 hours to obtain a light yellow viscous sand suppressing and antiswelling agent product with an effec...

Embodiment 3

[0023] Example 3, weigh 27.28g of 1,2-propanediamine, and add it into a four-necked flask. Turn on stir bar (medium speed) and condensed water. The water bath is filled with clear water to control the reaction temperature. Weigh 72.72g hydrochloric acid (effective content is 37%), join in the constant pressure funnel, control the opening degree of piston, make hydrochloric acid drip in the flask slowly. In this process, pay attention to controlling the rate of addition of hydrochloric acid not to be too fast, and ensure that the reaction temperature is always within 50°C. When the pH is between 5 and 6, stop the dropwise addition and continue the reaction for 0.5h. Then 2 g of a terpolymer of acrylamide, dimethyldiallylammonium chloride and vinyltris(2-methoxyethoxy)silane are added. The temperature of the water bath was adjusted to 50° C., and the product was taken out after 4 hours of reaction to obtain a transparent viscous anti-sand and anti-swelling agent product with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com