A Porous Rectangular Waveguide Directional Coupler

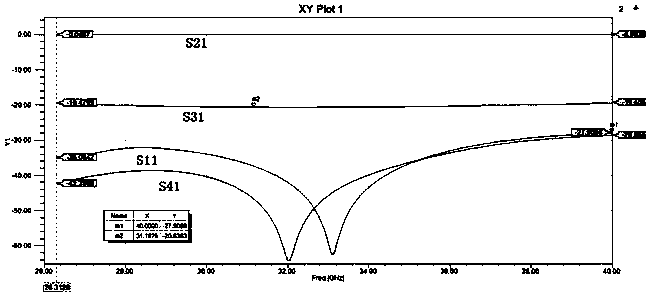

A technology of directional coupler and rectangular waveguide, which is applied in the direction of waveguide devices, circuits, connecting devices, etc., can solve the problems of high insertion loss, low directivity, difficult integration and processing, etc., and achieve small insertion loss, wide operating bandwidth, and directional The effect of sexual optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

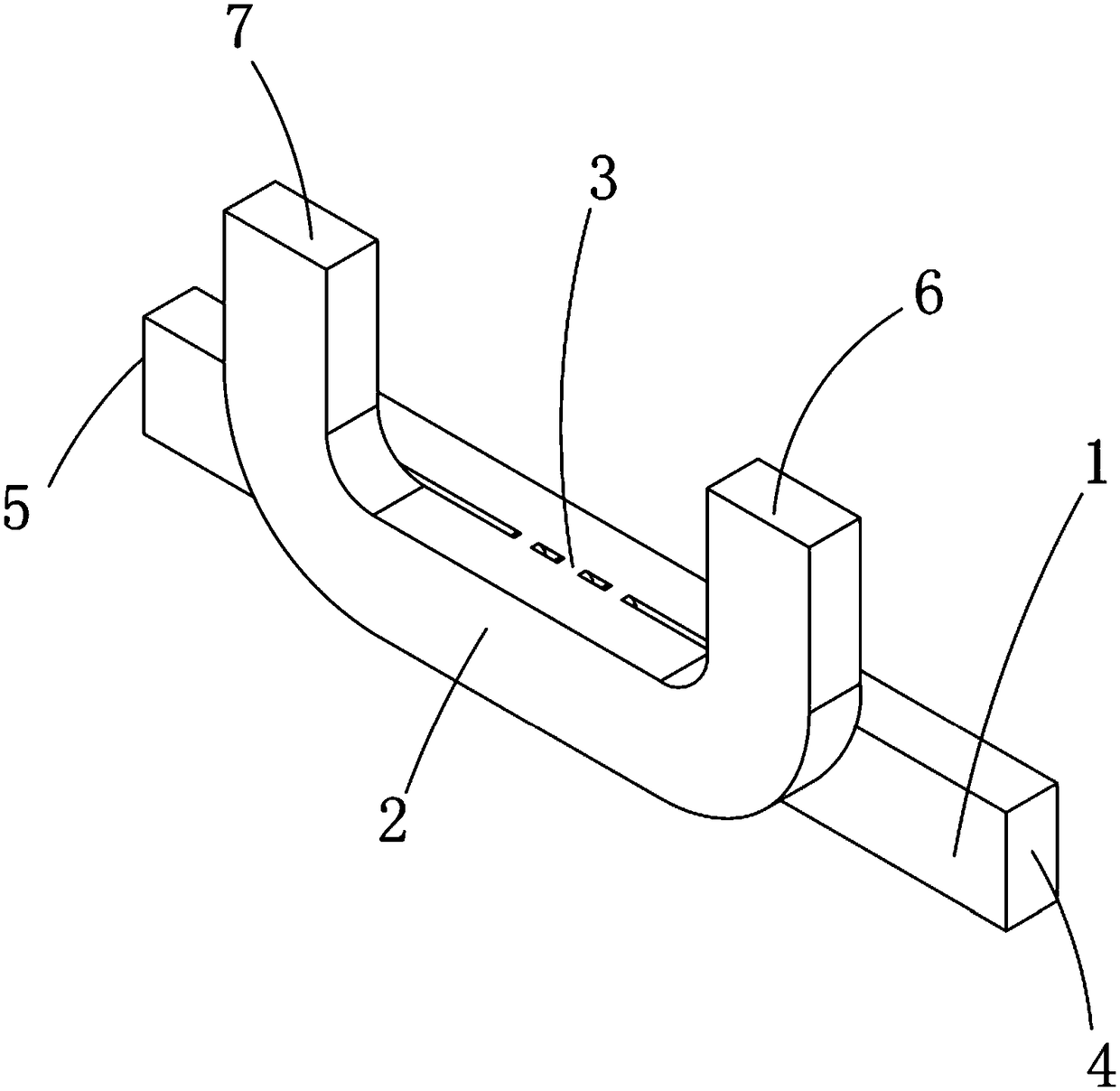

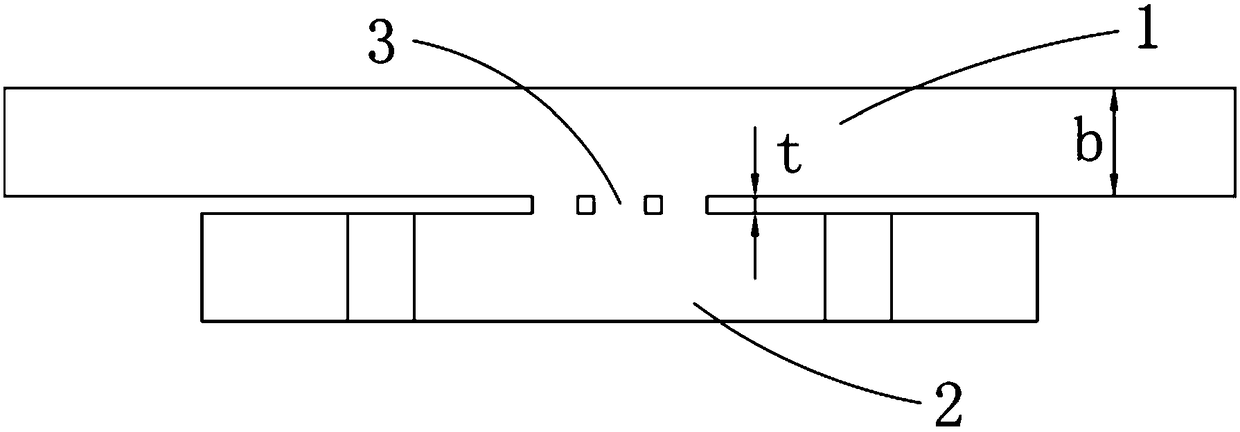

[0031] Such as figure 1 As shown, a kind of porous rectangular waveguide directional coupler of the present invention includes the main rectangular waveguide 1 as the microwave main channel, the secondary rectangular waveguide 2 as the sampling signal channel and the coupling hole 3 as the coupling channel; the main rectangular waveguide 1 of the main The mode H plane and the main mode H plane of the secondary rectangular waveguide 2 are parallel to each other, the main mode H plane mentioned here is the magnetic field plane; the main rectangular waveguide 1 and the sub rectangular waveguide 2 are isolated from each other, and the two are arranged along the axis of the main rectangular waveguide The coupling hole 3 of the main rectangular waveguide 1 is connected; one end of the main rectangular waveguide 1 is the input end 4, and the other end is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com