Method and device for removing mercury from flue gas through optical radiation chlorine atoms and hydroxide radicals

A technology of light radiation and chlorine atoms, which is applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of high application cost and unaffordable enterprises, and achieve simple equipment, small initial investment, and broad development and application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

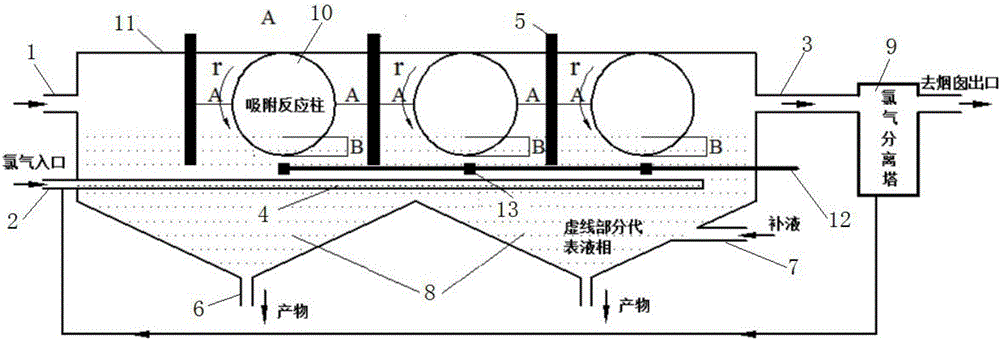

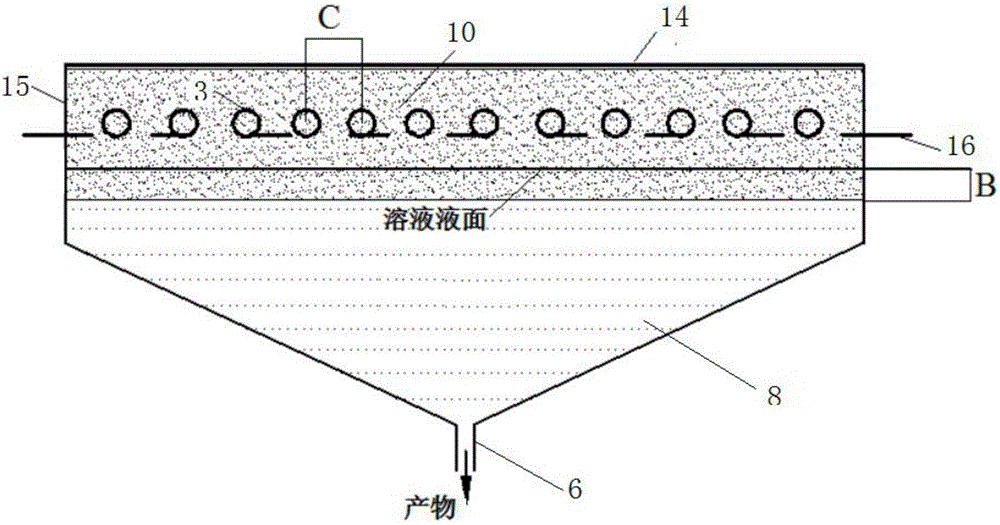

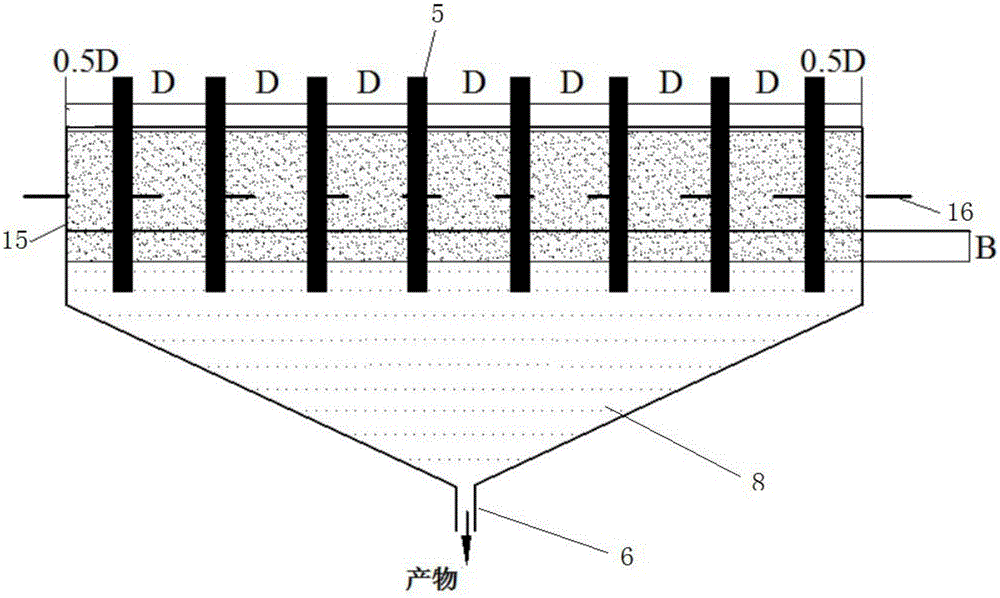

[0043] The vertical distance A between the adsorption reaction column 10 and the ultraviolet lamp 5 is 20 cm, the horizontal distance D between the ultraviolet lamp 5 and the ultraviolet lamp 5 is 20 cm, the distance C between the flue gas inlet 1 is 25 cm, and the chlorine gas aeration pipe 4 bulges out The average diameter of the small bubbles is 50 microns, the vertical distance or depth B of the adsorption reaction column 10 busbars entering the solution is 7cm, the ultraviolet lamp 5 and the quartz sleeve are inserted 15cm below the liquid surface, and the end surface of the ultrasonic transmitter and the bottommost part of the adsorption reaction column 10 Maintaining a vertical distance of 3 cm, the adsorption reaction column 10 rotates counterclockwise, the diameter of the adsorption reaction column 10 is 50 cm, and the rotational speed r is 15 rpm. The temperature of flue gas inlet 1 is 120°C, and the liquid-gas ratio is 8L / m 3 , the dosage of chlorine gas is 2.0L (ch...

Embodiment 2

[0045] The vertical distance A between the adsorption reaction column 10 and the ultraviolet lamp 5 is 20 cm, the horizontal distance D between the ultraviolet lamp 5 and the ultraviolet lamp 5 is 20 cm, the distance C between the flue gas inlet 1 is 25 cm, and the chlorine gas aeration pipe 4 bulges out The average diameter of the small bubbles is 50 microns, the vertical distance or depth B of the adsorption reaction column 10 busbars entering the solution is 7cm, the ultraviolet lamp 5 and the quartz sleeve are inserted 15cm below the liquid surface, and the end surface of the ultrasonic transmitter and the bottommost part of the adsorption reaction column 10 Maintaining a vertical distance of 3 cm, the adsorption reaction column 10 rotates counterclockwise, the diameter of the adsorption reaction column 10 is 50 cm, and the rotational speed r is 15 rpm. The flue gas inlet 1 temperature is 120°C, and the liquid-gas ratio is 5L / m 3 , the dosage of chlorine gas is 3.0L (chlor...

Embodiment 3

[0047] The vertical distance A between the adsorption reaction column 10 and the ultraviolet lamp 5 is 20 cm, the horizontal distance D between the ultraviolet lamp 5 and the ultraviolet lamp 5 is 20 cm, the distance C between the flue gas inlet 1 is 25 cm, and the chlorine gas aeration pipe 4 bulges out The average diameter of the small bubbles is 50 microns, the vertical distance or depth B of the adsorption reaction column 10 busbars entering the solution is 7cm, the ultraviolet lamp 5 and the quartz sleeve are inserted 15cm below the liquid surface, and the end surface of the ultrasonic transmitter and the bottommost part of the adsorption reaction column 10 Maintaining a vertical distance of 3 cm, the adsorption reaction column 10 rotates counterclockwise, the diameter of the adsorption reaction column 10 is 50 cm, and the rotational speed r is 15 rpm. The flue gas inlet 1 temperature is 120°C, and the liquid-gas ratio is 5L / m 3 , the dosage of chlorine gas is 1.0L (chlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com