A platinum-supported catalyst based on a porous graphene/nanoceramic sandwich structure and its preparation method

A technology of porous graphene and nano-ceramic, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc. It can solve the problems of expensive and complicated preparation and achieve deposition Uniform, uniform particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

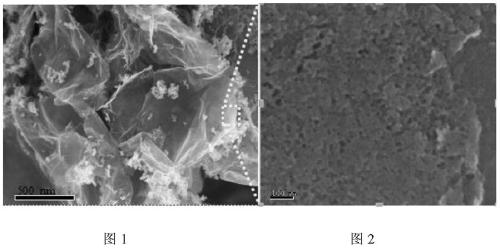

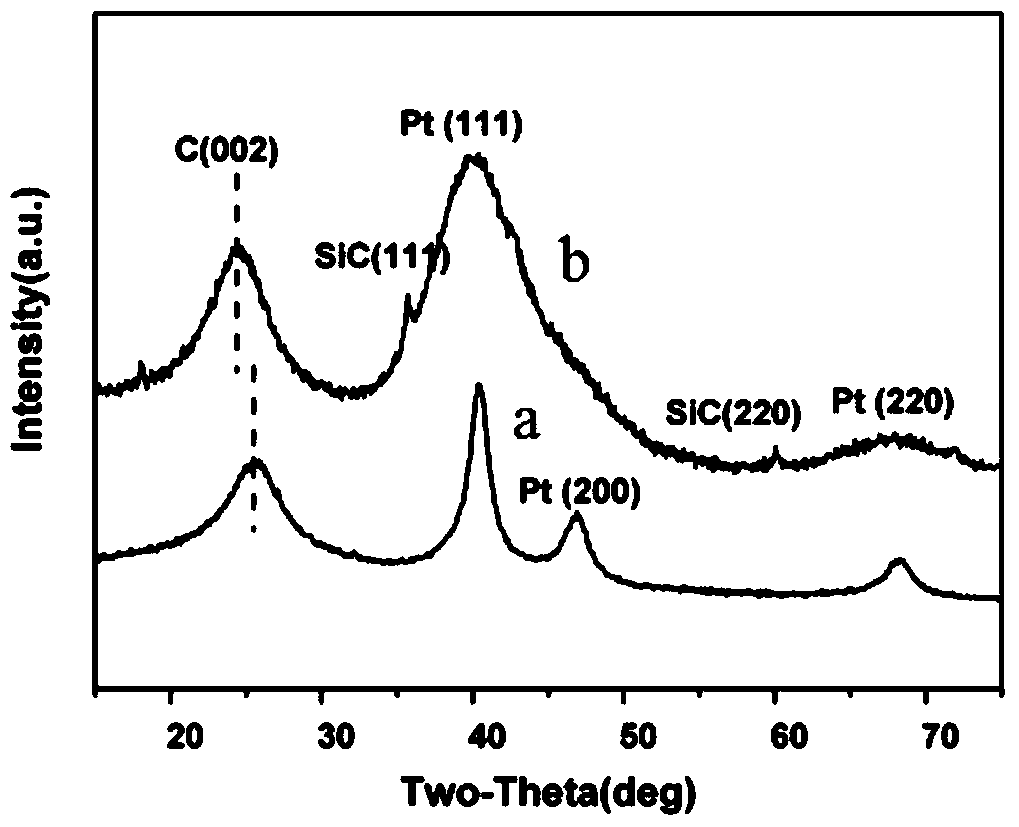

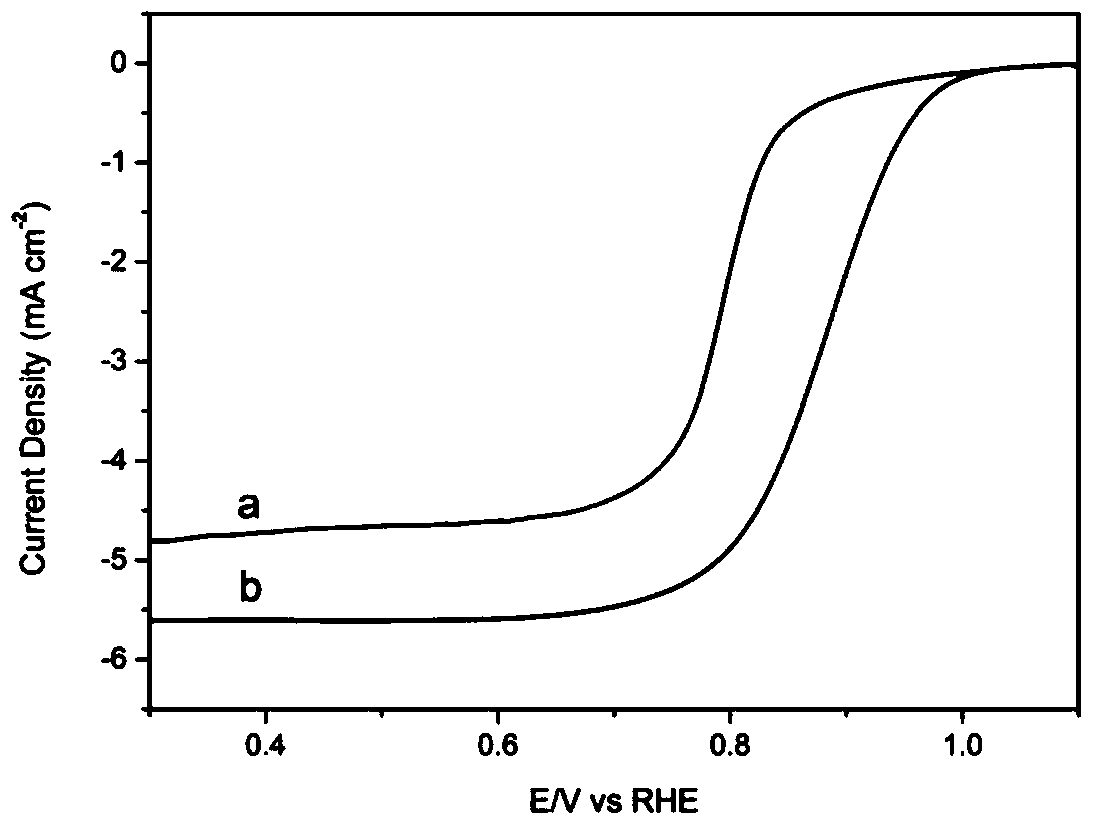

[0031] The preparation of embodiment 1 porous graphene / silicon carbide supported platinum catalyst

[0032] (1) Weigh 0.25g of porous graphene (PG), add 100mL of deionized water, and disperse ultrasonically for 30min at 150W; add 0.25g of silicon carbide (SiC, 40nm), mix and stir at 60°C for 4h, freeze After drying, a porous graphene / silicon carbide carrier with a sandwich structure is obtained;

[0033] (2) Put the carrier in (1) into an atomic layer deposition device, and use trimethyl(methylcyclopentadienyl) platinum (IV) as a platinum source and oxygen to deposit platinum nanoparticles on the surface of the carrier. During the entire atomic deposition reaction process, high-purity nitrogen is continuously fed as a carrier gas, and the pressure in the chamber is controlled below 4mbar. The atomic layer deposition reaction temperature is 250°C. In order to ensure sufficient vapor pressure, the platinum source was heated to 65°C. To prevent condensation in the pipeline, the...

Embodiment 2

[0035] The preparation of embodiment 2 porous graphene / tungsten carbide supported platinum catalyst

[0036] (1) Weigh 0.25g of porous graphene (PG), add 100mL of deionized water, and disperse ultrasonically for 90min at 100W; add 0.05g of tungsten carbide (WC, 50nm), mix and stir at 80°C for 6h, freeze After drying, a porous graphene / tungsten carbide carrier with a sandwich structure is obtained;

[0037] (2) Put the carrier in (1) into the atomic layer deposition equipment, the whole atomic deposition reaction process is the same as step (2) in Example 1, the difference is that the atomic layer deposition reaction temperature is 275 ° C, repeat 120 times Cycle, that is, obtain porous graphene / tungsten carbide supported platinum catalyst.

Embodiment 3

[0038] The preparation of embodiment 3 porous graphene / boron carbide supported platinum catalyst

[0039] (1) Weigh 0.25g porous graphene (PG), add 100mL deionized water, and disperse ultrasonically for 60min at 120W; add 0.1g boron carbide (B 4 C, 50nm), after fully mixing and stirring at 80°C for 6h, freeze-drying to obtain a porous graphene / boron carbide carrier with a sandwich structure;

[0040] (2) Put the carrier in (1) into the atomic layer deposition equipment, the whole atomic deposition reaction process is the same as step (2) in Example 1, the difference is that the atomic layer deposition reaction temperature is 260 ° C, repeat 110 times Cycle, that is, to obtain porous graphene / boron carbide-supported platinum catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com