A kind of viscous solid waste treatment device and its treatment method and application

A solid waste and treatment method technology, applied in the direction of grain treatment, etc., can solve the problems of fast heat transfer speed, difficult treatment of high-viscosity solid waste, high heat conduction efficiency, etc., and achieve the effect of non-uniform fluidization at the bottom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

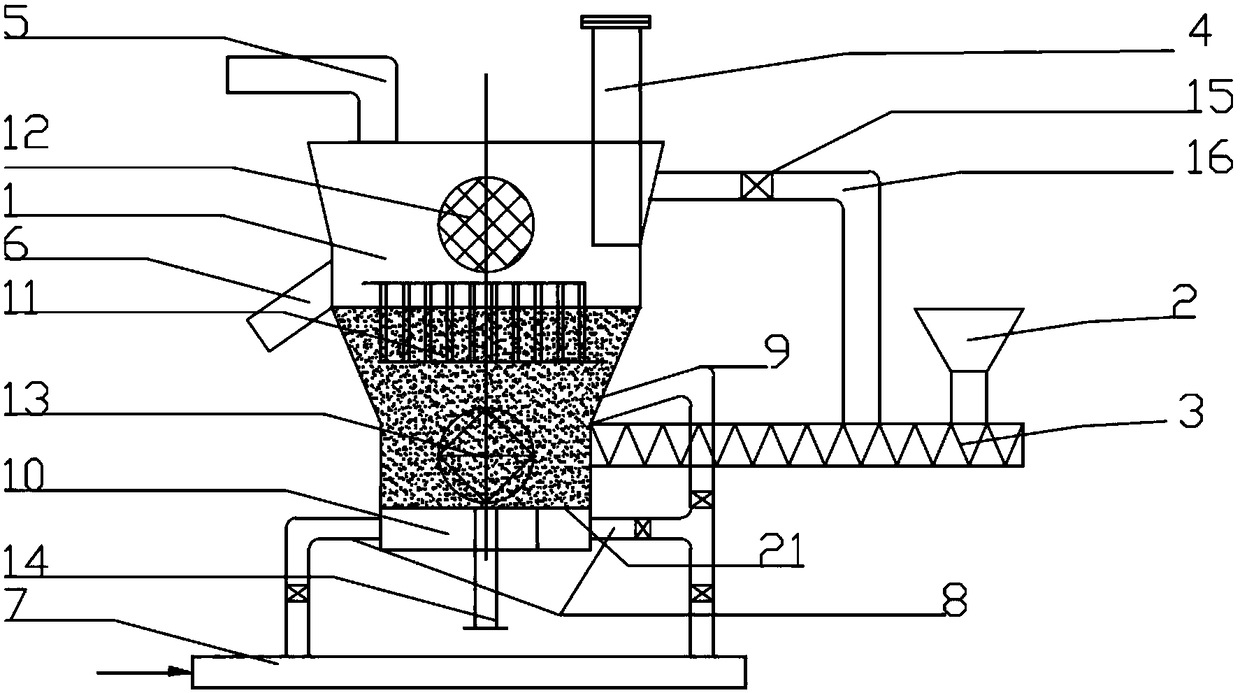

[0070] Such as figure 1 As shown, this embodiment provides a high-concentration viscous solid waste treatment device with a heat exchange unit 11 inside, wherein the heat exchange unit 11 is a wear-resistant oil bath heat exchanger.

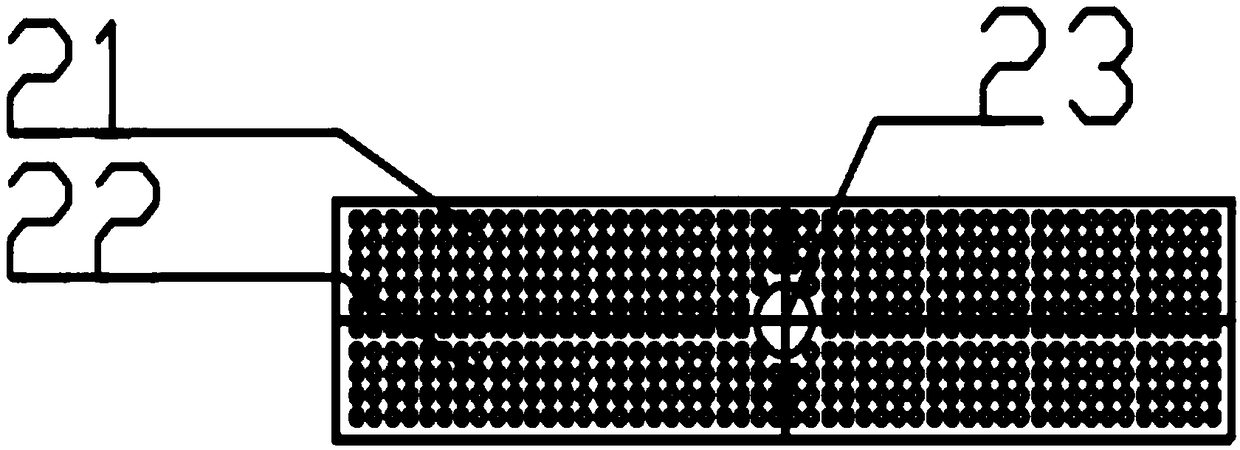

[0071] The device includes a dense phase reactor 1, feeding equipment 3, heat carrier feed channel 4, gas outlet 5, solid outlet 6, air chamber 10, distribution plate 21, primary air inlet 8, secondary air inlet 9 and slagging pipe 14; wherein, the feeding equipment 3 is arranged in the middle of the dense phase reactor 1, the heat carrier feed channel 4 is located at the top of the dense phase reactor 1 and extends into the dense phase reactor 1, and the gas outlet 5 is arranged at On the top of the dense phase reactor 1 and on the side opposite to the heat carrier feed channel (4), the solid outlet 6 is arranged in the middle of the dense phase reactor 1, the air chamber 10 is located at the bottom of the dense phase reactor 1, and the distribu...

Embodiment 2

[0081] This embodiment provides the treatment method of the high-concentration viscous solid waste treatment device described in Example 1. In this embodiment, bagasse is used as the high-viscosity solid waste, and the specific method is as follows:

[0082]The heat carrier particles enter the dense phase reactor 1 through the heat carrier feed channel 4, and at this time, the shut-off valve of the slag discharge pipe 14 of the dense phase reactor 1 is in a closed state to prevent the heat carrier particles from flowing out. Simultaneously, the fluidizing air is passed into the dense phase reactor 1 through the air chamber 10, so that the heat carrier particles are in the shape of bubbling bubbles, the temperature in the dense phase reactor 1 begins to rise, and the shut-off valve of the slag discharge pipe 14 is opened to make the Cold ash flows out of the shut-off valve. When the temperature of the heat carrier particles rises to 500°C, close the shut-off valve of the slag d...

Embodiment 3

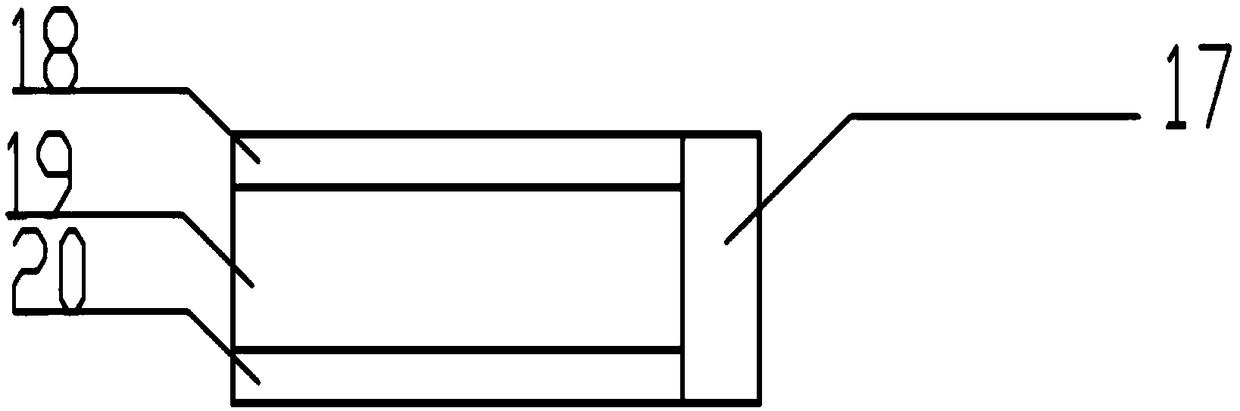

[0085] Such as Figure 4 As shown, this embodiment provides a high-concentration viscous solid waste treatment device with a heat exchange unit 11 inside, wherein the heat exchange unit 11 is a gas phase heat exchanger.

[0086] In this embodiment, the structure of the high-concentration viscous solid waste treatment device is the same as that of the device in embodiment 1 except that the gas phase heat exchanger is arranged in the gas phase.

[0087] The treatment method of the high-concentration viscous solid waste treatment device described in this embodiment is the same as that in Example 2.

[0088] Through the treatment method described in this embodiment, the material thermal conversion efficiency can reach 95%, the CO concentration in the discharged flue gas is far lower than the national standard requirement, and the energy conversion efficiency can reach more than 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com