Device and method for stepwise extracting mixed organic matters in high-salinity wastewater by using combined membrane

A technology for high-salt wastewater and organic matter, applied in chemical instruments and methods, extraction water/sewage treatment, multi-stage water treatment, etc., can solve problems such as high cost and difficult treatment, achieve low cost, improve treatment efficiency, and efficiently remove Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

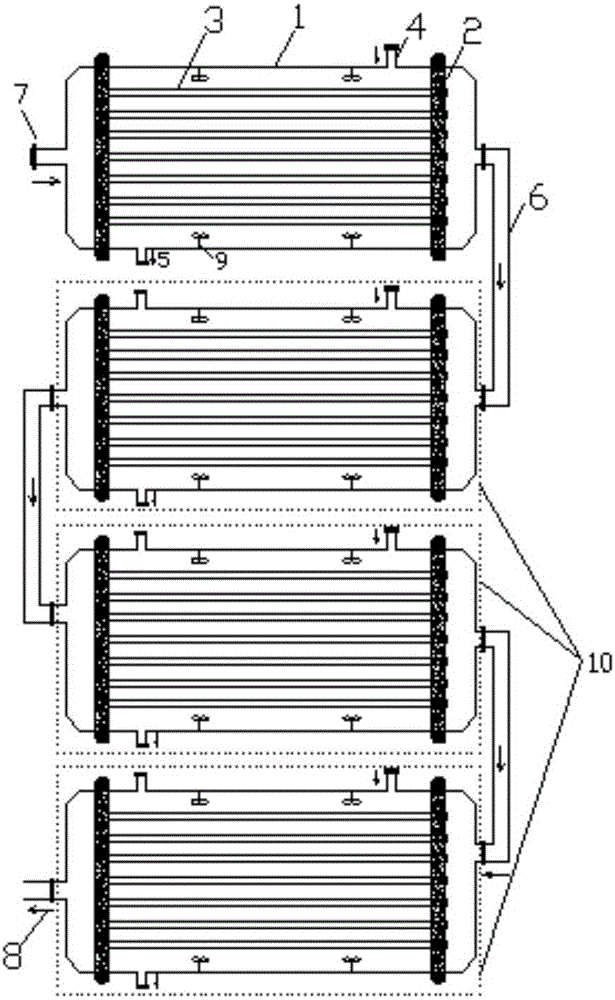

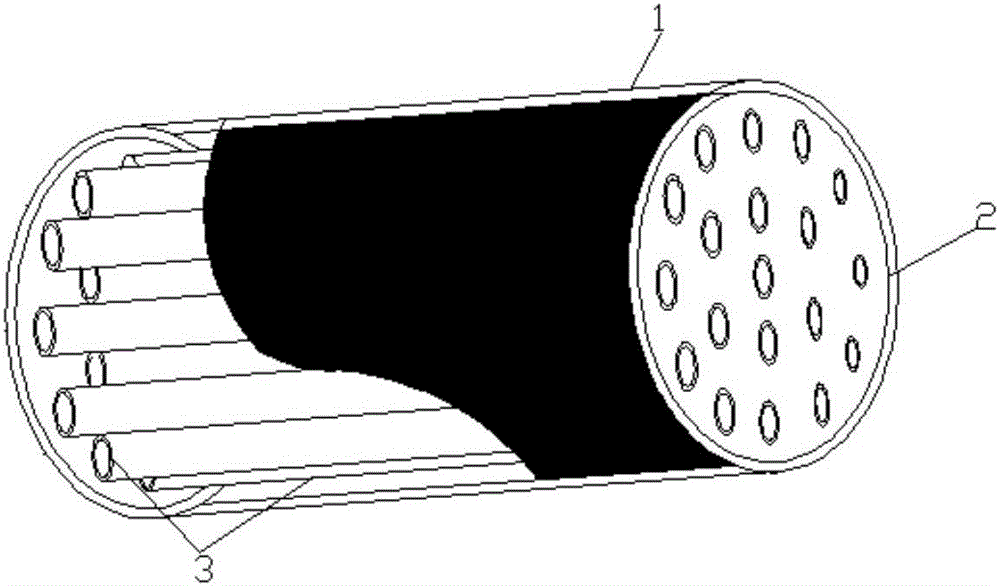

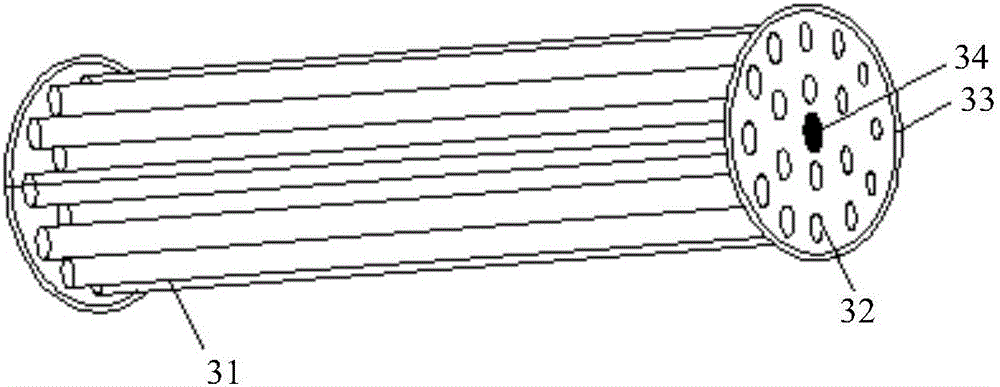

[0042] Embodiment 1, organic acid wastewater treatment of a certain chemical plant:

[0043] The enterprise wastewater mainly contains formic acid, acetic acid, propionic acid, benzoic acid and aromatic acid. The concentration is about 1000mg / L, and the salt content in the raw wastewater is about 6%. It cannot be treated by conventional biological methods. see Figure 4 In the present invention, after the waste water is pretreated, it is directly pumped into the membrane extraction system, the flow rate is controlled to 40L / h, and the temperature is room temperature. The membrane unit 10 is successively selected as a polydimethylsiloxane membrane unit, including 20 membrane modules 3, wherein the specification of the membrane tube 31 is 3mm (inner diameter) × 5mm (outer diameter), that is, the wall thickness is 2mm, and the length is 5m , the total number is 400; the polymethylvinylsiloxane membrane unit includes 20 membrane modules 3, wherein the specification of the membr...

Embodiment 2

[0044] Embodiment 2, a certain chemical plant organic wastewater treatment

[0045] The enterprise's wastewater mainly contains phenolic compounds, organic acid compounds, and a small amount of ester compounds and aromatic hydrocarbons. The concentration is 1200mg / L, and the salt content in the raw wastewater is about 8%. After the wastewater is pretreated, it is pumped into the membrane extraction system, the flow rate is controlled at 60L / h, and the temperature is 20°C. The membrane material is successively selected as a polydimethylsiloxane membrane unit, including 25 membrane modules 3, wherein the specification of the membrane tube 31 is 3mm (inner diameter) × 5mm (outer diameter), the length is 5m, and the total number is 500; Methyl vinyl siloxane membrane unit, including 25 membrane modules 3, wherein the specification of the membrane tube 31 is 3mm (inner diameter) × 5mm (outer diameter), the length is 5m, and the total number is 500 pieces; polyphenylmethoxy The si...

Embodiment 3

[0046] Embodiment 3, a chemical plant organic wastewater treatment:

[0047] The enterprise's wastewater mainly contains methyl orange, benzoic acid and o-toluic acid. The concentration is about 500mg / L, and the salt content in the raw wastewater is about 10%. It cannot be treated by conventional biological methods. In the present invention, after the wastewater is pretreated, it is directly pumped into the membrane extraction system, the flow rate is controlled at 25L / h, and the temperature is 40°C. The membrane unit 10 is four polydimethylsiloxane membrane units connected in series, and each polydimethylsiloxane membrane unit includes 10 membrane modules 3, wherein the specification of the membrane tube 31 is 5 mm (inner diameter) × 6 mm (outer diameter), length is 5m, and the total number is 200; assemble the membrane module 3 and the membrane unit 10, then connect the membrane unit 10 in series, and the extract solution in the polydimethylsiloxane membrane unit is extrac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com