A kind of red mud and fly ash geopolymer material formula and preparation method thereof

A geopolymer and fly ash technology, applied in cement production, etc., can solve the problems of red mud consumption capacity and secondary utilization, high processing cost, high cost, etc., to solve the problem of stockpiling and pollution, and to prepare The method is simple and the effect of not consuming energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

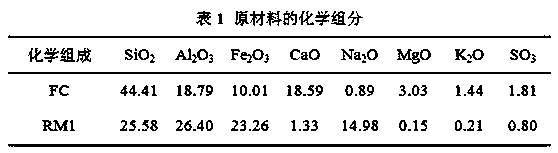

[0021] 1. Raw materials include undisturbed red mud (RM), Class C fly ash (FC) and NaOH solutions of different concentrations from Shandong Aluminum Power Plant. The chemical compositions of RM and FC are shown in Table 1.

[0022]

[0023] 2. Prepare a sufficient amount of red mud, fly ash and sodium hydroxide solution according to step (1);

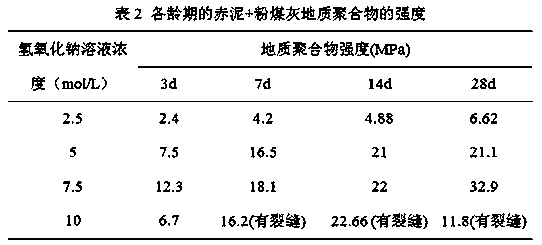

[0024] 3. According to the mass ratio of red mud: fly ash: sodium hydroxide solution = 1:1: (0.8~1), take a sufficient amount of raw materials, and the molar concentration of sodium hydroxide solution includes 2.5, 5, 7.5 and 10mol / L .

[0025] 4. Complete the production of the test piece according to step (3) and step (4);

[0026] 5. Take it out after 24-36 hours of curing in the oven at 50-80°C, demould, and cure at room temperature to the design age, including several different ages of 3d, 7d, 14d and 28d;

[0027] 6. According to the strain rate of 0.3mm / min, test the compressive strength of the specimens of different ages, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com