Microwave dielectric ceramic material doped with ReAlO3 and preparation method thereof.

A technology of microwave dielectric ceramics and formulations, applied in the field of electronic component materials, can solve the problems of system dielectric constant reduction and achieve the effects of promoting grain growth, performance improvement, and high dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

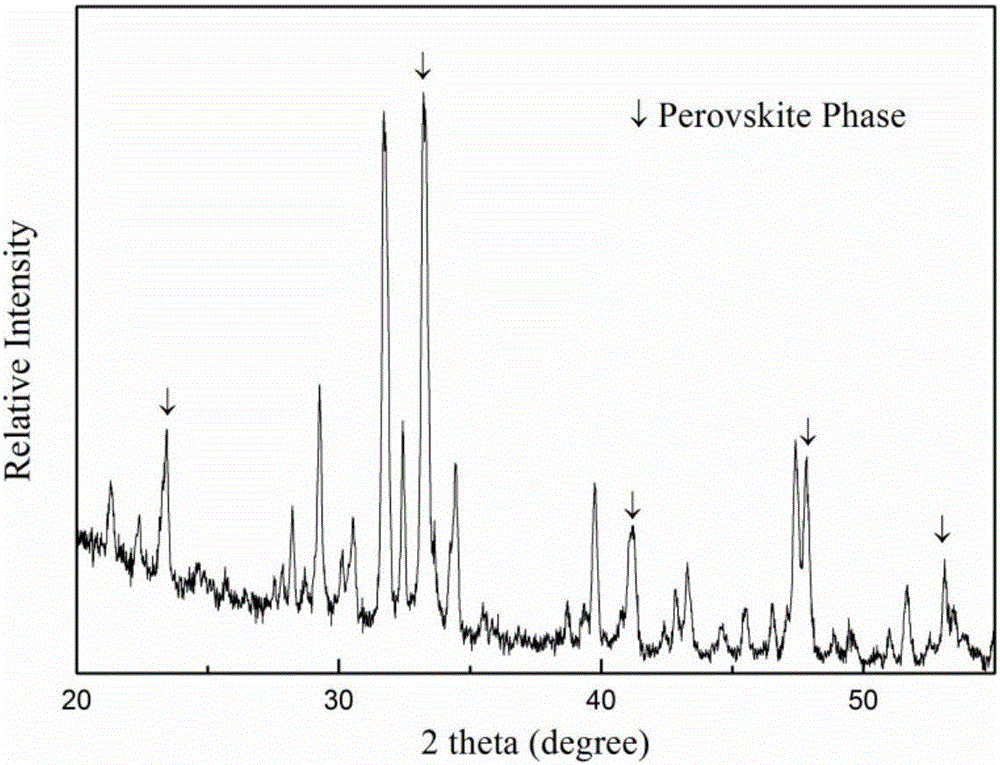

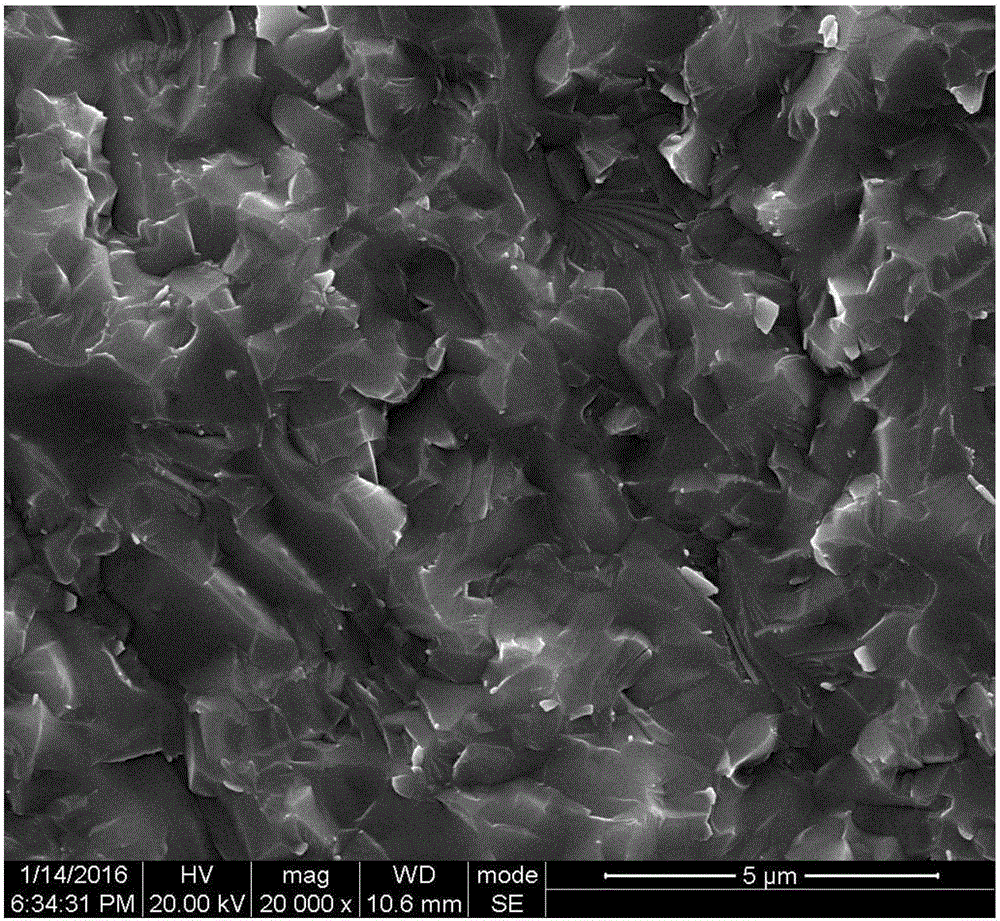

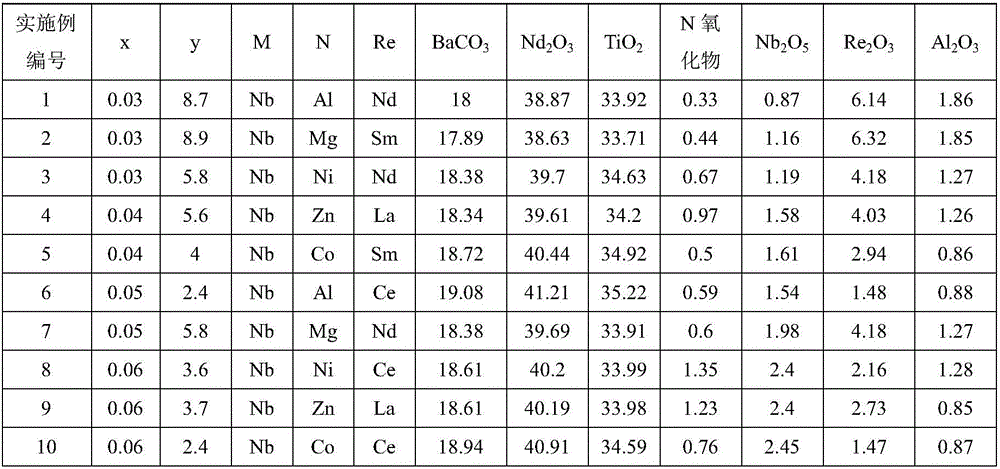

[0037] The invention provides a kind of adding ReAlO 3 (high temperature pre-fired) high-performance microwave-based dielectric ceramic material, the material formula is Ba 3.75 Nd 9.5 (Ti 1-x C x ) 18 o 54 +y wt%ReAlO 3 , C=MN, where x is the molar content ratio, 0.03≤x≤0.06; 2≤y≤9, y is in Ba 3.75 Nd 9.5 (Ti 1-x C x )18 o 54 Based on the addition of ReAlO 3 The mass percent content (ie y wt% represents every 100 grams of Ba 3.75 Nd 9.5 (Ti 1-x C x ) 18 o 54 Material added y grams of ReAlO 3 ); M represents Nb whose valence is higher than tetravalent, N represents another element (Zn, Mg, Ni, Co, Al) whose valence is lower than tetravalent and whose ionic radius is similar to Ti, M and N are substituted at the same time, Re is a common rare earth element (Re=Nd, Sm, La, Ce).

[0038] N is one of Zn, Co, Ni, Mg and Al. When MN is substituted at the same time, if N is Al, then the molar ratio N:M=1:1, if N is one of Zn, Co, Ni, Mg, then the total molar ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com