Method for preparing thiol-functionalized polyester with micro-reaction unit

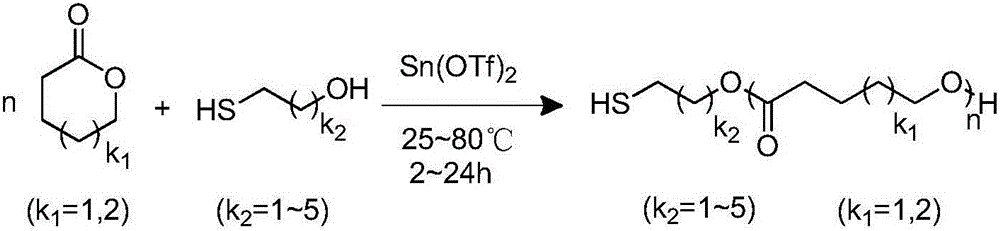

A micro-reaction device and functionalized technology, which is applied in the field of polymer chemistry, can solve the problems of poor molecular weight distribution control, harsh reaction conditions, and low thiol introduction rate, and achieve high thiol introduction rate, low cost, and strong operability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

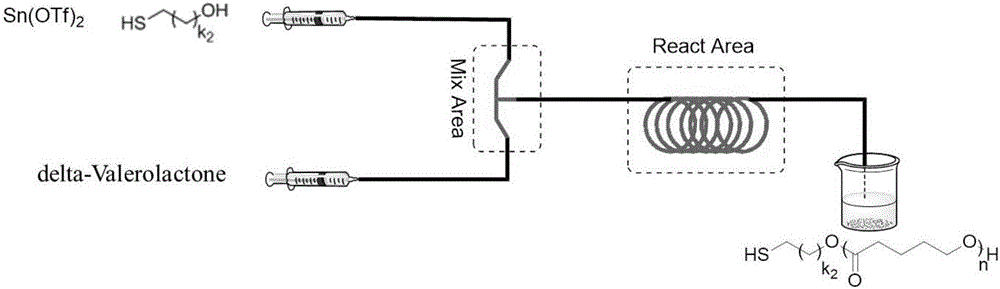

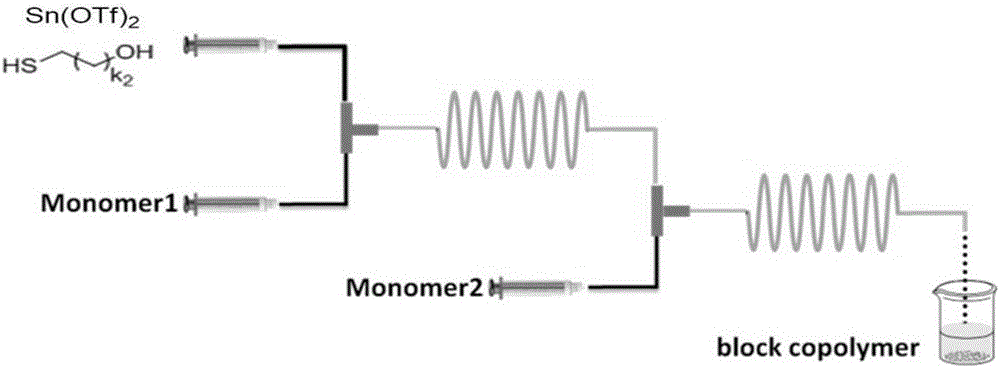

Method used

Image

Examples

Embodiment 1

[0038] Before the experiment, argon and freshly steamed toluene were used to remove water and air from the micro-reaction device.

[0039] Two groups of samples were injected, and two 20mL schlenk bottles were taken, corresponding to bottle number A and bottle B. Bake under a high temperature oven, and use a schlenk device to replace the gas three times, so that the inside of the two schlenk bottles is in an argon atmosphere. Liquid A is a mixed organic solvent solution of catalyst and initiator, and solid catalyst Sn(OTf) is added in the glove box 2 (55.2mg, 0.1324mmol, 1eq), then add the initiator 6-mercapto-1-hexanol MH (1777.3mg, 13.24mmol, 100eq) with a micro syringe, and finally add 10mL of newly steamed toluene and tetrahydrofuran mixed solvent (4: 1), A solution is prepared and kept for use. Liquid B is pure δ-valerolactone, add pure δ-VL to bottle B with a syringe for future use.

[0040] To carry out the reaction, pump liquid A and liquid B into two 50mL syringes ...

Embodiment 2

[0042] Before the experiment, argon and freshly steamed toluene were used to remove water and air from the micro-reaction device.

[0043] Two groups of samples were injected, and two 20mL schlenk bottles were taken, corresponding to bottle number A and bottle B. Bake under a high temperature oven, and use a schlenk device to replace the gas three times, so that the inside of the two schlenk bottles is in an argon atmosphere. Liquid A is a mixed organic solvent solution of catalyst and initiator, and solid catalyst Sn(OTf) is added in the glove box 2 (55.2mg, 0.1324mmol, 1eq), then add the initiator 6-mercapto-1-hexanol MH (1777.3mg, 13.24mmol, 100eq) with a micro syringe, and finally add 10mL of newly steamed toluene and tetrahydrofuran mixed solvent (4: 1), A solution is prepared and kept for use. Liquid B is pure δ-valerolactone, add pure δ-VL to bottle B with a syringe for future use.

[0044] To carry out the reaction, pump liquid A and liquid B into two 50mL syringes ...

Embodiment 3

[0046] Before the experiment, argon and freshly steamed toluene were used to remove water and air from the micro-reaction device.

[0047] Two groups of samples were injected, and two 50mL schlenk bottles were taken, corresponding to bottle number A and bottle B. Bake under a high temperature oven, and use a schlenk device to replace the gas three times, so that the inside of the two schlenk bottles is in an argon atmosphere. Liquid A is a mixed organic solvent solution of catalyst and initiator, and solid catalyst Sn(OTf) is added in the glove box 2 (55.2mg, 0.1324mmol, 1eq), then add initiator 6-mercapto-1-hexanol MH (1777.3mg, 13.24mmol, 100eq) with a micro syringe, finally add 34mL of newly steamed toluene and tetrahydrofuran mixed solvent (4: 1), A solution is prepared and kept for use. Liquid B is pure δ-valerolactone, add pure δ-VL to bottle B with a syringe for future use.

[0048] To carry out the reaction, pump liquid A and liquid B into two 50mL syringes respecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dispersity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com