Humic acid soil conditioner and its composition, preparation method and use method

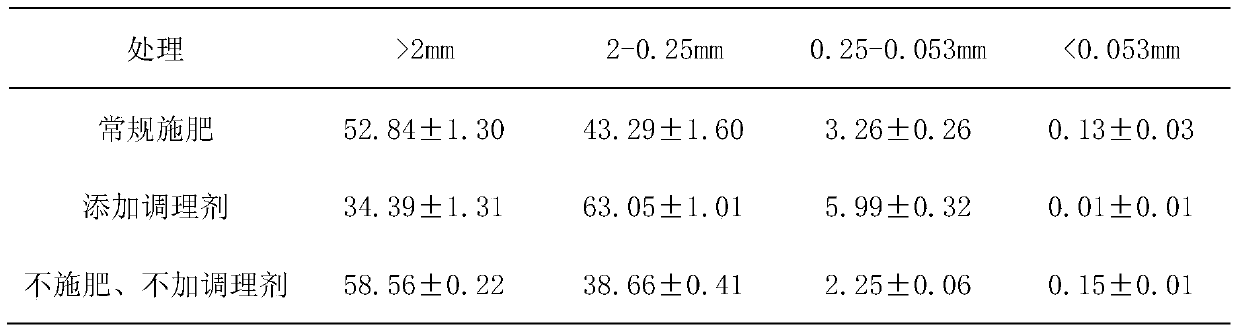

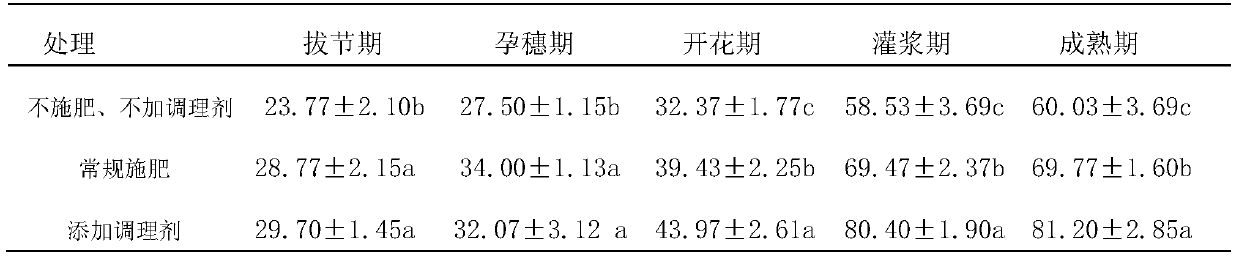

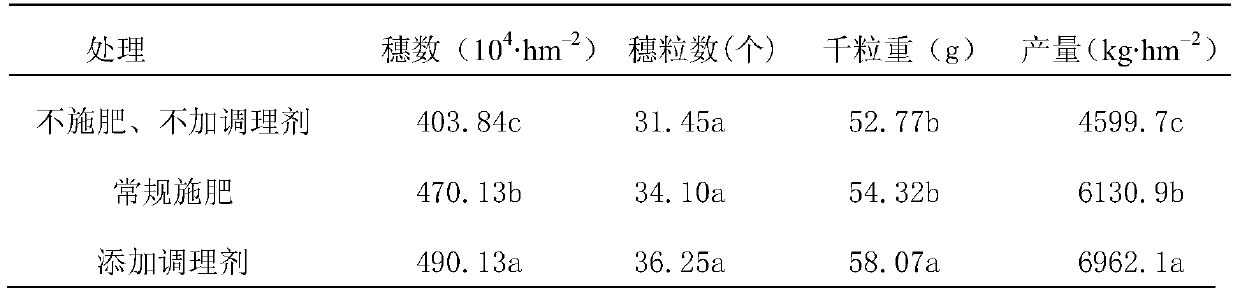

A technology of soil conditioner and humic acid, applied in the direction of soil conditioning materials, fertilizer mixtures, chemical instruments and methods, etc., can solve the problems of complex components, harmful crops, farmland pollution, etc., to improve the structure of soil aggregates and increase soil pores Degree, reduce the effect of soil bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh the components (kg) according to the following weights:

[0031] Cotton meal 12.0, KOH solution 2.5, polyacrylamide 1.3, urea 1.34, potassium dihydrogen phosphate 1.00, potassium sulfate 0.06.

[0032] A preparation method of humic acid soil conditioner:

[0033] (1) Grind 12.0kg of cottonseed meal, pass through a 80-mesh sieve, put the sieved fine powder into a reaction vessel, add 2.5kg of KOH solution and 25kg of distilled water in turn to obtain a mixed solution, heat the mixed solution to 70°C and keep stirring , stand still after reacting for 80min, and cool at the same time until the reaction materials are separated into layers to obtain cottonseed humic acid;

[0034] (2) Add 1.3kg polyacrylamide to cottonseed humic acid, stir to dissolve polyacrylamide completely, cool and filter to remove insoluble matter, mix 1.34kg urea, 1.00kg potassium dihydrogen phosphate, and 0.06kg potassium sulfate to obtain humic acid Acid soil conditioner.

[0035] A kind of...

Embodiment 2

[0041] Weigh the components (kg) according to the following weights:

[0042] Cotton meal 8.3, KOH solution 2, potassium polyacrylate 0.5, urea 0.1, potassium dihydrogen phosphate 0.04, potassium sulfate 0.02.

[0043] A preparation method of humic acid soil conditioner:

[0044] (1) Grind 8.3kg of cottonseed meal, pass through a 100-mesh sieve, put the sieved fine powder into a reaction vessel, add 2.0kg of KOH solution and then add 10kg of distilled water to obtain a mixed solution, heat the mixed solution to 80°C and Stir continuously, let stand after reacting for 40 minutes, and cool at the same time until the reaction materials are separated into layers to obtain cottonseed humic acid;

[0045] (2) Add 0.5kg potassium polyacrylate to cottonseed humic acid, stir to dissolve potassium polyacrylate completely, cool and filter to remove insoluble matter, mix 0.1kg urea, 0.04kg potassium dihydrogen phosphate, and 0.02kg potassium sulfate to obtain humic acid Acid soil condit...

Embodiment 3

[0053] Weigh the components (kg) according to the following weights:

[0054] Cotton meal 16.7, KOH solution 3, polyacrylic acid 1.9, urea 1.5, potassium dihydrogen phosphate 0.7, potassium sulfate 0.8.

[0055] A preparation method of humic acid soil conditioner:

[0056] (1) Crush 16.7kg of cottonseed meal, pass through a 80-mesh sieve, take the sieved fine powder and put it into a reaction container, add 3kg of KOH solution in turn, and then add 35kg of distilled water to obtain a mixed solution, heat the mixed solution to 100°C and keep stirring , stand still after reacting for 110min, and cool at the same time until the reaction materials are separated into layers to obtain cottonseed humic acid;

[0057] (2) Add 1.9kg polyacrylic acid to cottonseed humic acid, stir to dissolve polyacrylic acid completely, cool and filter to remove insoluble matter, mix 1.5kg urea, 0.7kg potassium dihydrogen phosphate, and 0.8kg potassium sulfate to obtain humic acid soil conditioner. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com