Method for fermenting cellulosic ethanol by thick mash semi-simultaneous saccharification by batch material supplementation

A cellulosic ethanol and fed-batch technology, which is applied in the field of biomass resource recycling and biomass energy, can solve problems such as unsatisfactory production efficiency and poor technical comprehensive indicators, and achieve the effect of reducing commercial costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Steam explosion treatment: Put corn stalks into a steam explosion reactor at 200°C for 10 minutes to obtain a solid-liquid separation, and dry the solid part at 60°C for 6 hours; after steam explosion treatment, the three major components are: fiber The content of xylan is 33%, the content of xylan is 3.32%, and the content of lignin is 36.1%.

[0024] 2) Treatment with alkaline hydrogen peroxide solution: then use 2% (w / w) hydrogen peroxide solution at pH 11.5, solid-to-liquid ratio 1:20, and temperature 25°C for 6 hours and 3 times . The obtained solid-liquid mixture is then subjected to solid-liquid separation, and then washed with hot water until neutral. Finally, dry it at 60°C to obtain a dry solid rich in cellulose. The content of the three major components after treatment with alkaline hydrogen peroxide solution is 61.2% of cellulose, 5.21% of hemicellulose and 9.26% of lignin.

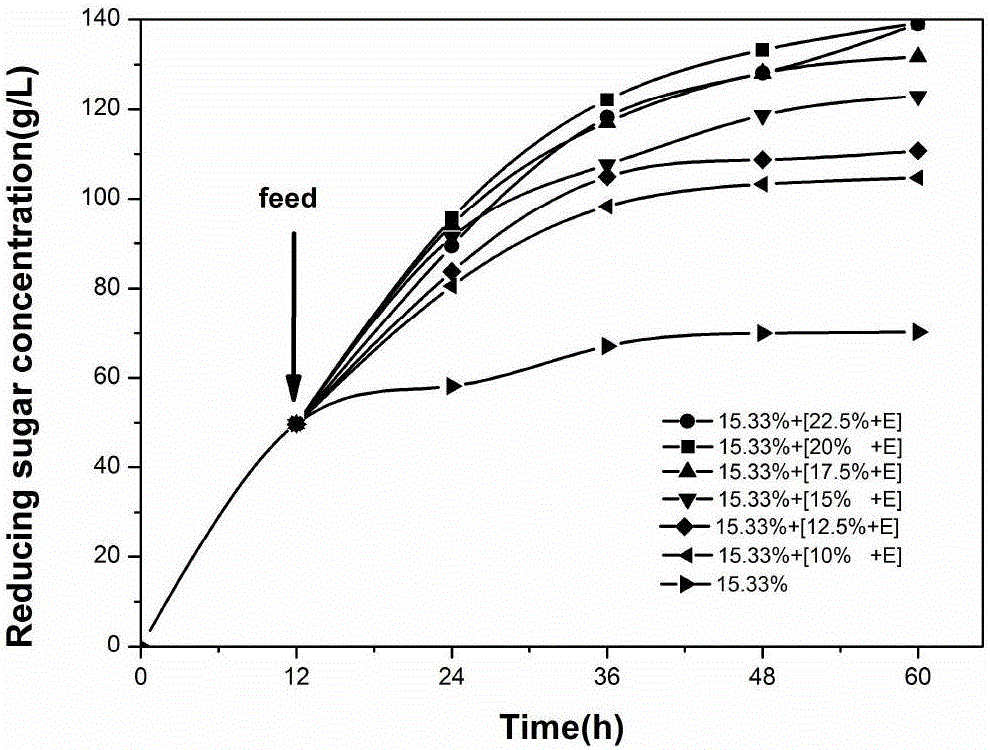

[0025] 3) Feed-batch semi-saccharification concentrated mash to ferment ethan...

Embodiment 2

[0027] 1) Steam explosion treatment: Put corn stalks into a steam explosion reactor at 200°C for 10 minutes to obtain a solid-liquid separation, and dry the solid part at 60°C for 6 hours; after steam explosion treatment, the three major components are: fiber The content of xylan is 33%, the content of xylan is 3.32%, and the content of lignin is 36.1%.

[0028] 2) Alkaline hydrogen peroxide solution treatment: then use 4% (w / w) hydrogen peroxide solution at pH 11.5, solid-to-liquid ratio 1:8, temperature 25°C, treatment time 6h, treatment 2 times . The obtained solid-liquid mixture is then subjected to solid-liquid separation, and then washed with hot water until neutral. Finally, dry it at 60°C to obtain a dry solid rich in cellulose. The content of the three major components after treatment with alkaline hydrogen peroxide solution is 62.6% of cellulose, 4.71% of hemicellulose and 8.54% of lignin.

[0029] 3) Fed-batch semi-simultaneous saccharification and fermenting con...

Embodiment 3

[0031] 1) Steam explosion treatment: Put corn stalks into a steam explosion reactor at 200°C for 10 minutes to obtain a solid-liquid separation, and dry the solid part at 60°C for 6 hours; after steam explosion treatment, the three major components are: fiber The content of xylan is 33%, the content of xylan is 3.32%, and the content of lignin is 36.1%.

[0032] 2) Alkaline hydrogen peroxide solution treatment: then use 4% (w / w) hydrogen peroxide solution at pH 11.5, solid-to-liquid ratio 1:8, temperature 25°C, treatment time 6h, treatment 2 times . The obtained solid-liquid mixture is then subjected to solid-liquid separation, and then washed with hot water until neutral. Finally, dry it at 60°C to obtain a dry solid rich in cellulose. The content of the three major components after treatment with alkaline hydrogen peroxide solution is 62.6% of cellulose, 4.71% of hemicellulose and 8.54% of lignin.

[0033]3) Feed-batch semi-saccharification concentrated mash to ferment et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com