3D printing based method for preparing antibacterial cobalt based dental crown

A 3D printing and antibacterial cobalt technology, which is applied in the field of preparation of antibacterial cobalt-based crown products, can solve the problems of excessive heavy metal release and substandard mechanical properties, and achieve the effect of improving compactness, high strength and reducing the formation of pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

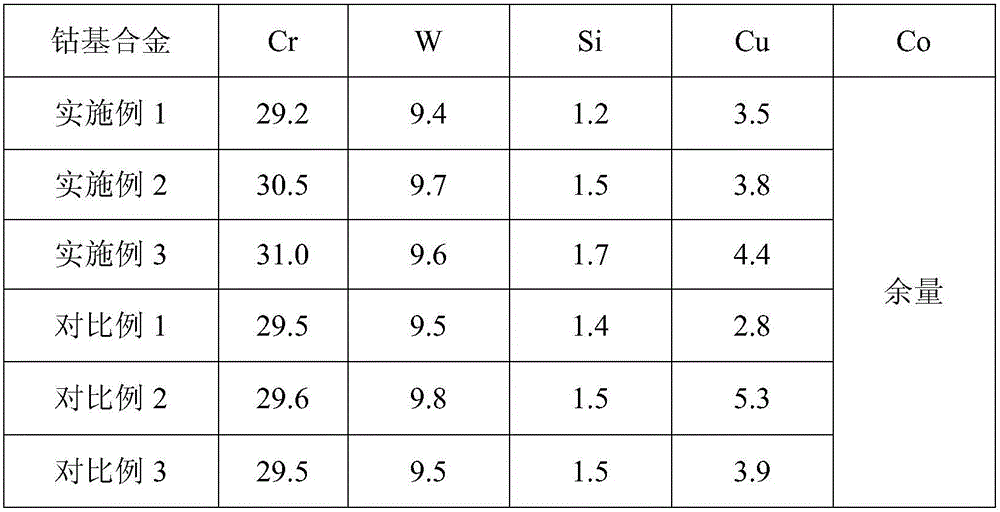

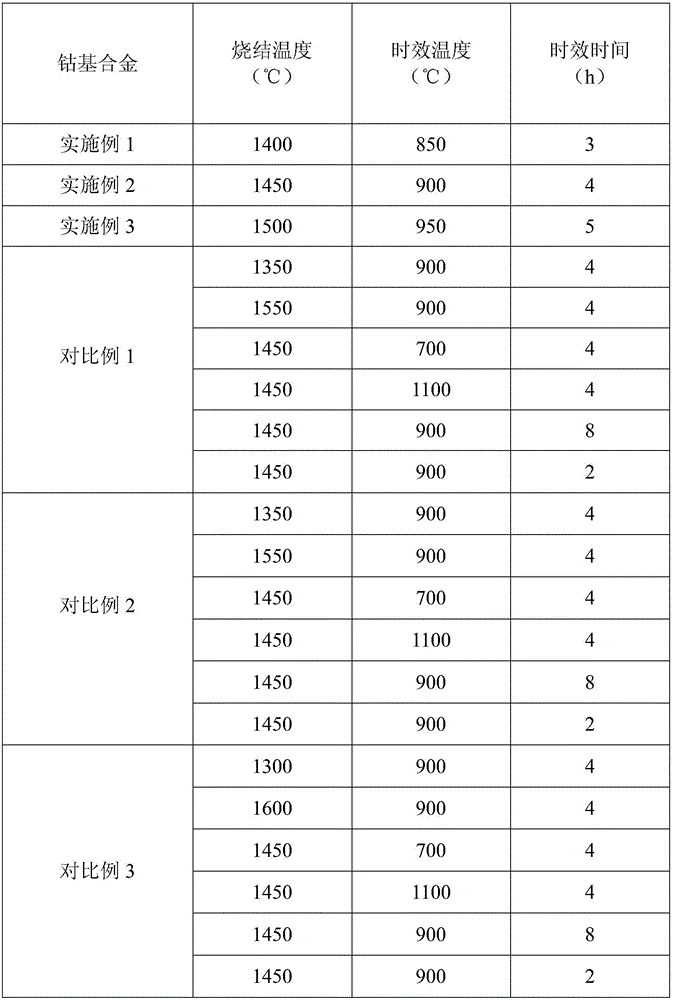

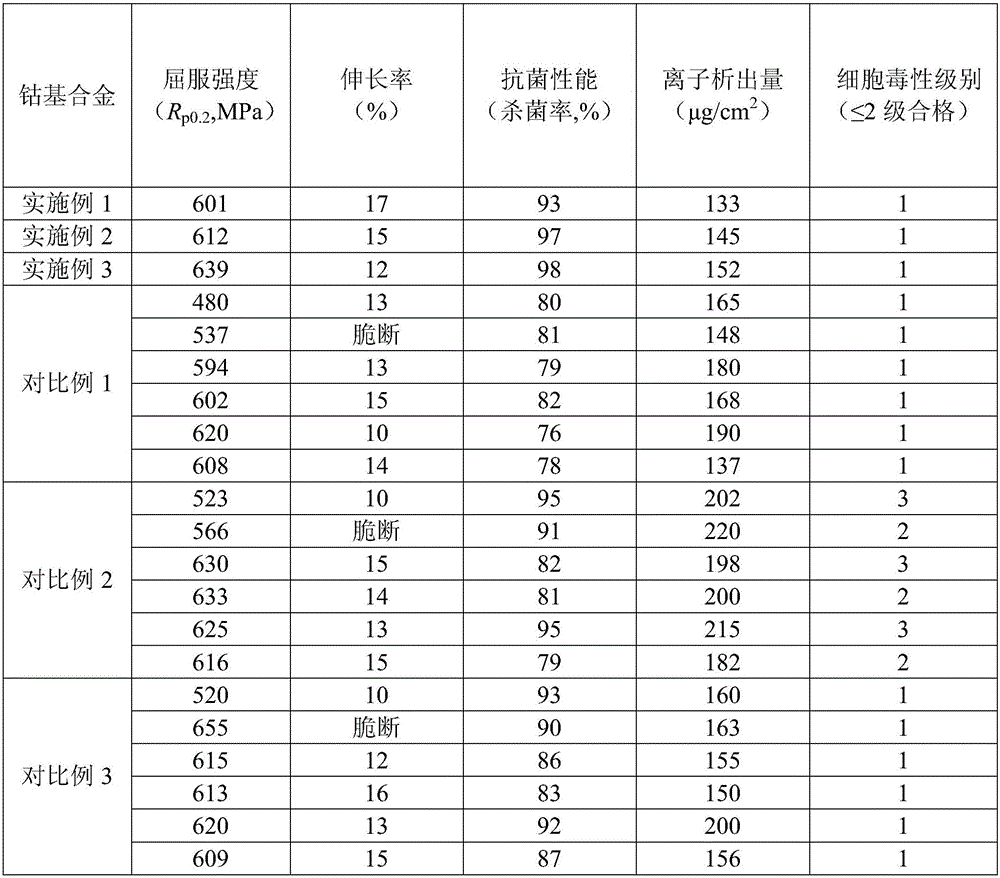

[0020] According to the chemical composition range set by the antibacterial cobalt-based alloy material for crown products of the present invention, 15 kilograms of vacuum induction furnaces are used to smelt 10 kilograms of cobalt-based alloys in each of Example 1-3 and Comparative Example 1-3. The chemical composition is shown in the table. 1.

[0021] Table 1 The chemical composition of the antibacterial cobalt-based alloys of the examples and comparative examples (wt.%)

[0022]

[0023] The preparation steps are:

[0024] Step 1, by vacuum induction melting, the antibacterial metal copper in the embodiment and the comparative example is added to the cobalt-based alloy, so that it is fully homogenized, and the antibacterial cobalt-based alloy is obtained;

[0025] Step 2, using an inert gas atomization to obtain a spherical cobalt-based alloy powder, and sieving to prepare an antibacterial cobalt-based alloy powder with an average particle size of 30 microns;

[0026]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com