12kV current-carrying 1250A solid insulation switchgear

A solid-insulated switch and current-carrying technology, applied in switchgear, switchgear setting, switchgear setting with resin casing, etc., can solve the problem of insufficient distance between connecting busbars, too many edges and corners of conductive parts, and deformation of key parts. Aging and other problems, to achieve the effect of improving the ability and service life of breaking current, avoiding uneven conduction problems, and high dielectric strength recovery speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

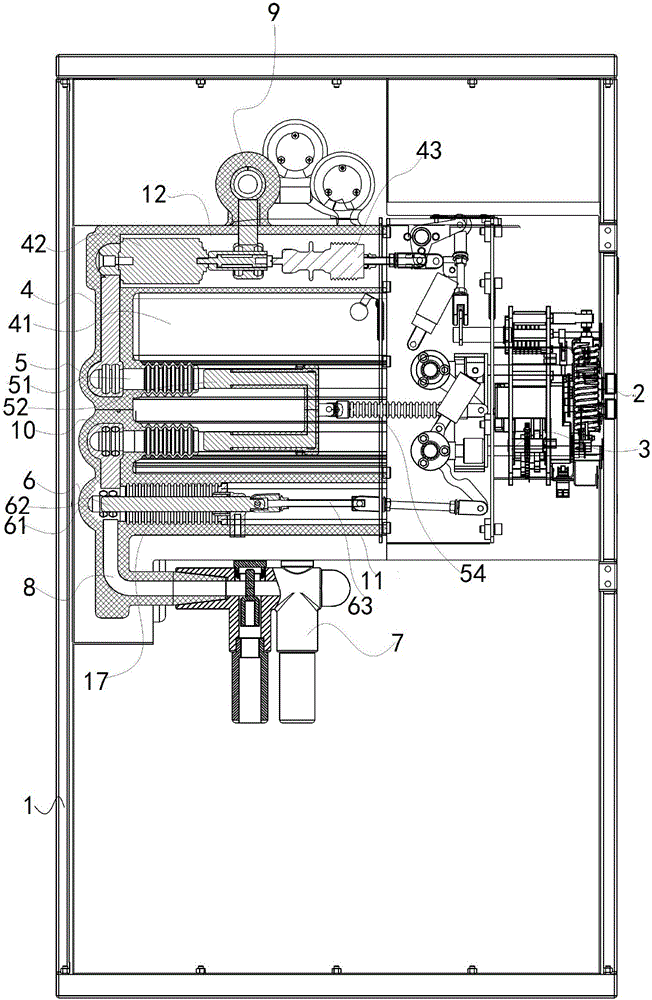

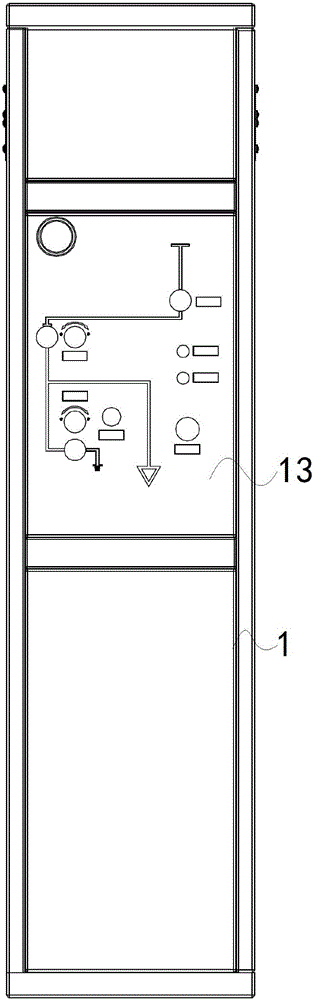

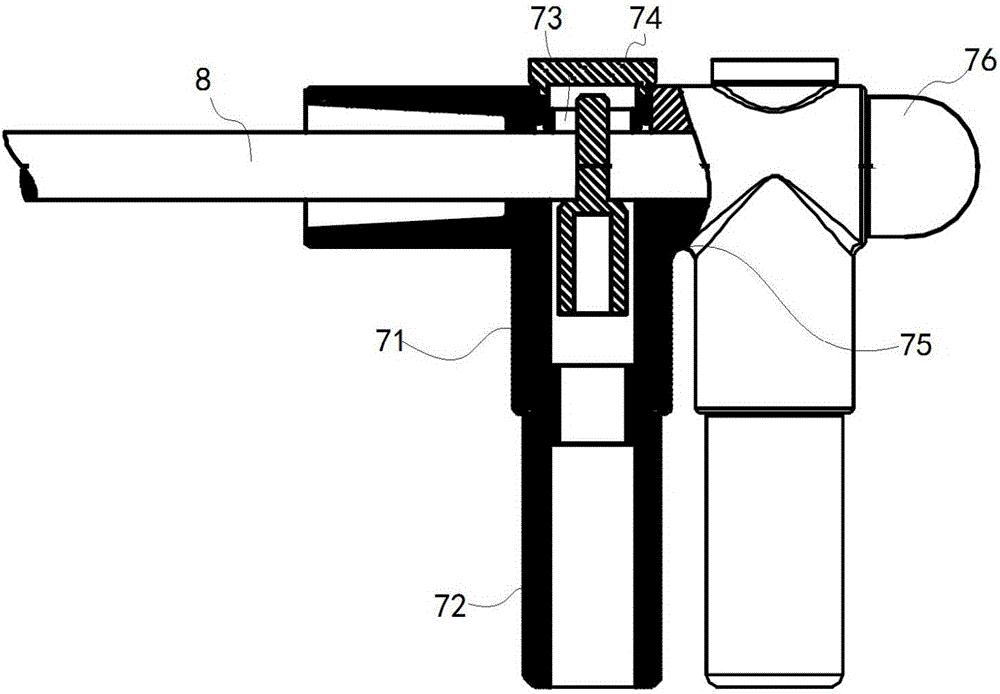

[0036] Such as Figure 1-7 As shown, the specific embodiment of the present invention is a 12kV current-carrying 1250A solid insulated switchgear, including a box body 1, a panel 13, a locking mechanism 3, a spring energy storage operating mechanism 2, a busbar seat 9, and an outgoing line insulating seat 7 , the middle part of the box body 1 is provided with an insulating square cylinder composed of an upper insulating base 12 and a lower insulating base 11, and the labyrinth of increasing the insulating creepage distance between the upper insulating base 12 and the lower insulating base 11 A polytetrafluoroethylene insulating board 14 is arranged in the groove, and a vacuum switch 4, a disconnector 5, a grounding switch 6, a bus bar seat 9, and an outgoing line insulating seat 7 are respectively arranged in the upper insulating base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com