Preparation method of edible protein stable Pickering emulsion

A stable and emulsion technology, applied in the field of Pickering emulsion, can solve the problems of toxicity, human harm, inedibility, etc., and achieve the effects of simple operation, easy availability of raw materials, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method for edible protein stable Pickering emulsion, comprising the following steps:

[0033] (1) Prepare an acetic acid solution with a mass concentration of acetic acid of 1%, and add chitosan equivalent to 0.05% of the mass of the acetic acid solution into the acetic acid solution to fully hydrate it.

[0034] (2) An ethanol solution with a mass concentration of ethanol of 70% was prepared, and wheat prolamin equivalent to 2.5% of the mass of the ethanol solution was added into the ethanol solution to fully dissolve it.

[0035] (3) Get the material obtained in step (2) that is equivalent to 100% of the volume of the material obtained in step (1) and add it to the material in step (1), and shear and homogenize for 4 minutes at a rotating speed of 6000r / min.

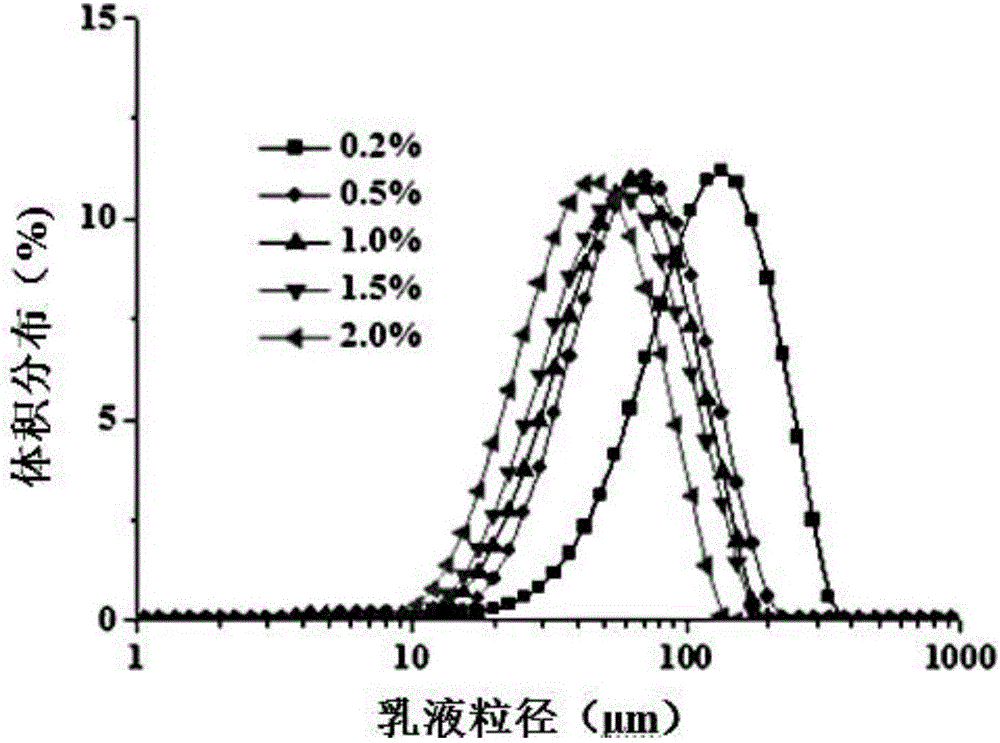

[0036] (4) The material obtained in the step (3) was rotatively evaporated in a water bath at 40° C. and 75 r / min until the mass concentration of wheat prolamin composite colloidal particles was 2%...

Embodiment 2

[0045] A preparation method for edible protein stable Pickering emulsion, comprising the following steps:

[0046] (1) Prepare an acetic acid solution with a mass concentration of acetic acid of 1%, and add chitosan equivalent to 0.05% of the mass of the acetic acid solution into the acetic acid solution to fully hydrate it.

[0047] (2) An ethanol solution with a mass concentration of ethanol of 70% was prepared, and wheat prolamin equivalent to 2.5% of the mass of the ethanol solution was added into the ethanol solution to fully dissolve it.

[0048] (3) Get the material obtained in step (2) that is equivalent to 100% of the volume of the material obtained in step (1) and add it to the material in step (1), and shear and homogenize for 4 minutes at a rotating speed of 6000r / min.

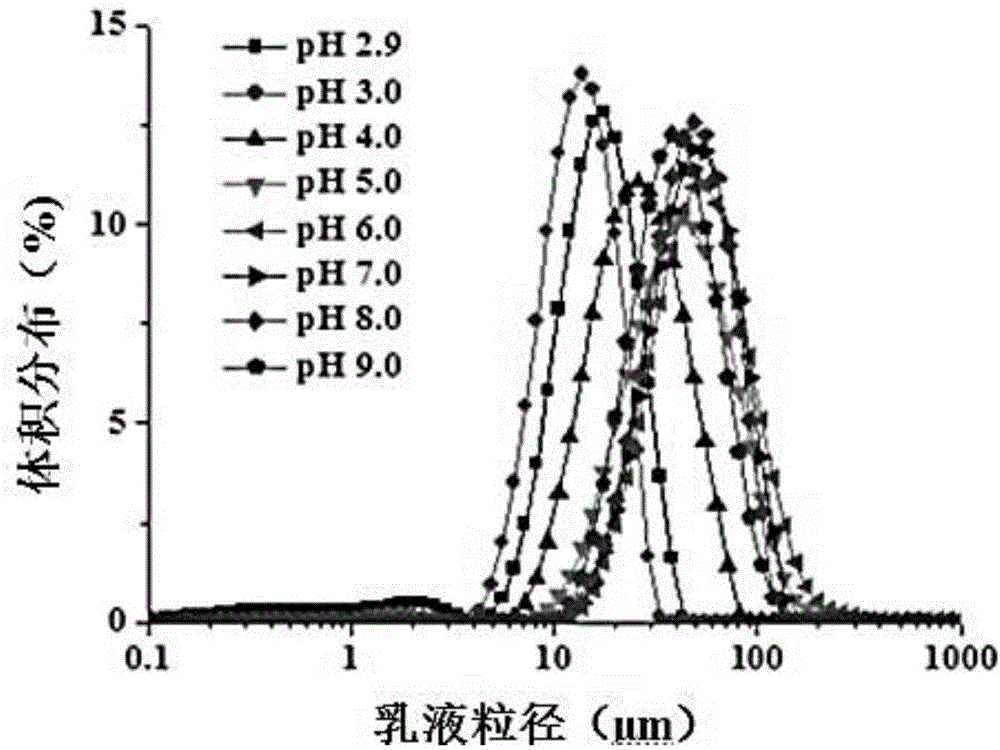

[0049] (4) The material obtained in the step (3) was rotatively evaporated in a water bath at 40° C. and 75 r / min until the mass concentration of wheat prolamin composite colloidal particles was 2%...

Embodiment 3

[0055] A preparation method for edible protein stable Pickering emulsion, comprising the following steps:

[0056] (1) Prepare an acetic acid solution with a mass concentration of acetic acid of 1%, and add chitosan equivalent to 0.05% of the mass of the acetic acid solution into the acetic acid solution to fully hydrate it.

[0057] (2) An ethanol solution with a mass concentration of ethanol of 70% was prepared, and wheat prolamin equivalent to 2.5% of the mass of the ethanol solution was added into the ethanol solution to fully dissolve it.

[0058] (3) Get the material obtained in step (2) that is equivalent to 100% of the volume of the material obtained in step (1) and add it to the material in step (1), and shear and homogenize for 4 minutes at a rotating speed of 6000r / min.

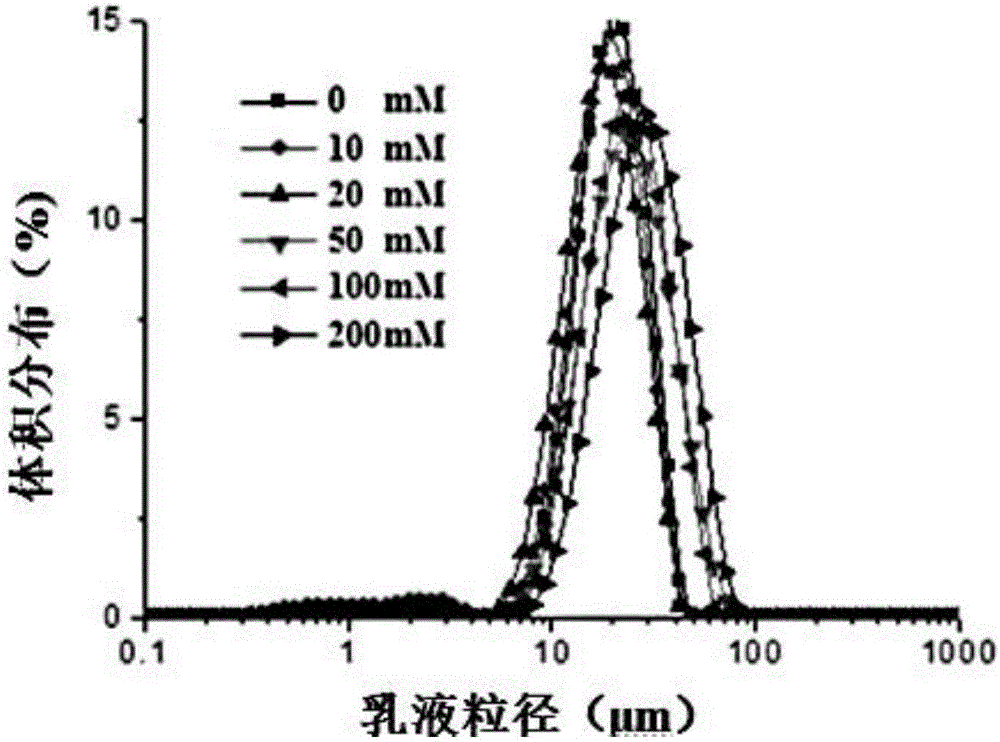

[0059] (4) The material obtained in the step (3) was rotatively evaporated in a water bath at 40° C. and 75 r / min until the mass concentration of wheat prolamin composite colloidal particles was 2%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com