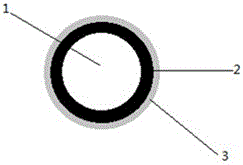

Monodisperse composite magnetic microsphere and preparation method thereof

A composite magnetic and monodisperse technology, applied in the field of magnetic materials, can solve the problems of time-consuming, complex preparation, and low temperature of monodisperse magnetic microspheres, and achieve the effects of simple process, simple preparation and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

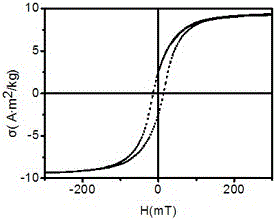

Embodiment 1

[0030] (1) Fe 2+ and Ni 2+ Adsorption: Disperse 6g of MF microspheres (particle size 2mm, molar ratio of melamine / formaldehyde = 1 / 3.3) in 250mL dissolved in 0.4mol / L FeCl 2 and 0.1mol / L NiCl 2 solution, ultrasonically dispersed for 10 min. Raise the temperature to 60°C and stir the reaction for 1 hour, centrifuge and wash with deionized water to obtain the adsorbed Fe 2+ and Ni 2+ MF microspheres.

[0031] (2) Fe 2+ , Fe 3+ and Ni 2+ Reduction of: the adsorbed Fe 2+ and Ni 2+ The MF microspheres were added to 78g of 40% hydrazine hydrate, ammonia water was added dropwise to adjust the pH to 10, the reaction was stirred in a water bath at 60°C for 4 hours, and iron-nickel-coated MF microspheres were obtained after magnetic separation.

[0032] (3) SiO 3 2- Adsorption: Add 250 mL of 1mol / L Na to the MF microspheres coated with iron and nickel 2 SiO 3 In the aqueous solution, stir and react in a water bath at 60°C for 1 hour. After magnetic separation, SiO is adsor...

Embodiment 2

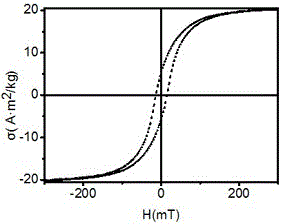

[0036] (1) Fe 2+ and Ni 2+ Adsorption: Disperse 6g of MF microspheres (particle size 3mm, molar ratio of melamine / formaldehyde = 1 / 3.3) in 250mL dissolved in 0.45mol / L FeSO 4 and 0.05mol / L Ni(AC) 2 solution, ultrasonically dispersed for 15 minutes. Raise the temperature to 50°C and stir the reaction for 1.5h, centrifuge and wash with deionized water to obtain the adsorbed Fe 2+ and Ni 2+ MF microspheres.

[0037] (2) Fe 2+ , Fe 3+ and Ni 2+ Reduction of: the adsorbed Fe 2+ and Ni 2+ The MF microspheres were added to 78g of 40% hydrazine hydrate, ammonia water was added dropwise to adjust the pH to 12, the reaction was stirred in a water bath at 60°C for 5 hours, and iron-nickel-coated MF microspheres were obtained after magnetic separation.

[0038] (3) SiO 3 2- Adsorption: Add the above-mentioned iron-nickel-coated MF microspheres to 250mL of 1mol / L Na 2 SiO 3 In an aqueous solution, stir and react in a water bath at 80°C for 1.5 hours. After magnetic separation...

Embodiment 3

[0043] (1) Fe 2+ and Ni 2+ Adsorption: Disperse 6g of MF microspheres (particle size 4mm, molar ratio of melamine / formaldehyde = 1 / 3.3) in 250mL dissolved in 0.4mol / L FeCl 2 , 0.4mol / L FeSO 4 and 0.2mol / L NiSO 4 solution, ultrasonically dispersed for 12 minutes. Raise the temperature to 80°C and stir the reaction for 1 hour, centrifuge and wash with deionized water to obtain the adsorbed Fe 2+ and Ni 2+ MF microspheres.

[0044] (2) Fe 2+ , Fe 3+ and Ni 2+ Reduction: Fe is adsorbed to the above 2+ and Ni 2+ Add 189g of sodium borohydride to the MF microspheres, add ammonia water dropwise to adjust the pH=10, stir and react in a water bath at 60°C for 3.5h, and obtain iron-nickel-coated MF microspheres after magnetic separation.

[0045] (3) SiO 3 2- Adsorption: Add the above-mentioned iron-nickel-coated MF microspheres to 250mL1.3mol / L Na 2 SiO 3 In an aqueous solution, stir and react in a water bath at 50°C for 1.5 hours, and SiO will be adsorbed after magnetic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com