Method for preparing magnetic carbon material by activating hydrothermal liquified biochar through CO2 and application of method

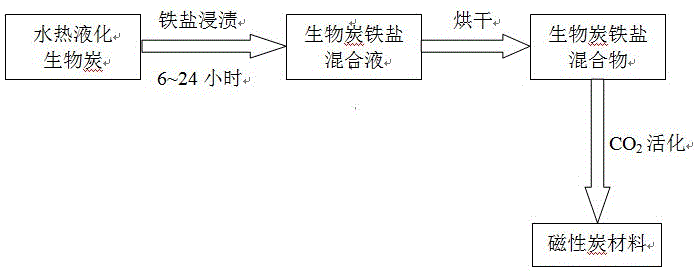

A hydrothermal liquefaction and biochar technology is applied in the fields of environmental protection and solid waste resource utilization, which can solve problems such as inconvenient separation, and achieve the effects of low cost, high porosity, and avoiding secondary pollution and resource waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Sieve dry Salix salix liquefaction biochar at 260°C with 20 meshes; add the sieved material into ferric chloride solution and soak for 12 hours, and filter, wherein the mass ratio of material to ferric chloride is 1:3.7 , the concentration of ferric chloride is 50 g / L. The impregnated material was dried in air at 80 °C for 4 h. The dried material was placed in a porcelain boat and placed in a tube-type atmosphere furnace under CO 2 Under atmosphere, the temperature was increased to 700 °C at a rate of 10 °C / min and maintained for 120 min. After the temperature is cooled to room temperature, take it out, wash with water, dry, and grind through a 100-mesh sieve to obtain the magnetic carbon material MC-1. Measured by the specific surface area measuring instrument, its specific surface area is 565 m 2 / g, the pore volumes of total pores and micropores are 0.31 and 0.21 cm, respectively 3 / g.

Embodiment 2

[0020] Sieve dry Salix salix liquefaction biochar at 260°C with 20 meshes; add the sieved material into ferric chloride solution and soak for 12 hours, and filter, wherein the mass ratio of material to ferric chloride is 1:3.7 , the concentration of ferric chloride is 50 g / L. The impregnated material was dried in air at 80 °C for 4 h. The dried material was placed in a porcelain boat and placed in a tube-type atmosphere furnace under CO 2 Under atmosphere, the temperature was increased to 750 °C at a rate of 10 °C / min and maintained for 120 min. After the temperature is cooled to room temperature, take it out, wash with water, dry, and grind through a 100-mesh sieve to obtain the magnetic carbon material MC-2. Measured by the specific surface area measuring instrument, its specific surface area is 664 m 2 / g, the pore volumes of total pores and micropores are 0.39 and 0.21 cm, respectively 3 / g.

Embodiment 3

[0022] Sieve dry Salix salix liquefaction biochar at 260°C with 20 meshes; add the sieved material into ferric chloride solution and soak for 12 hours, and filter, wherein the mass ratio of material to ferric chloride is 1:3.7 , the concentration of ferric chloride is 50 g / L. The impregnated material was dried in air at 80 °C for 4 h. The dried material was placed in a porcelain boat and placed in a tube-type atmosphere furnace under CO 2 Under atmosphere, the temperature was increased to 750 °C at a rate of 10 °C / min and maintained for 60 min. After the temperature is cooled to room temperature, take it out, wash it with water, dry it, and grind it through a 100-mesh sieve to obtain the magnetic carbon material MC-3. Measured by the specific surface area measuring instrument, its specific surface area is 402 m 2 / g, the pore volumes of total pores and micropores are 0.20 and 0.16 cm, respectively 3 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com