Preparation method and application of suspension type material of starch modified nanoscale zero-valent iron

A nano-zero-valent iron, modification and modification technology, applied in the field of nanomaterials and water environment pollution remediation, can solve problems such as shortening migration distance, easy particle agglomeration, oxidation, etc., and achieves broad implementation prospects, good environmental friendliness, and feasibility. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Selection of dispersant ratio and synthesis of modified nano zero-valent iron

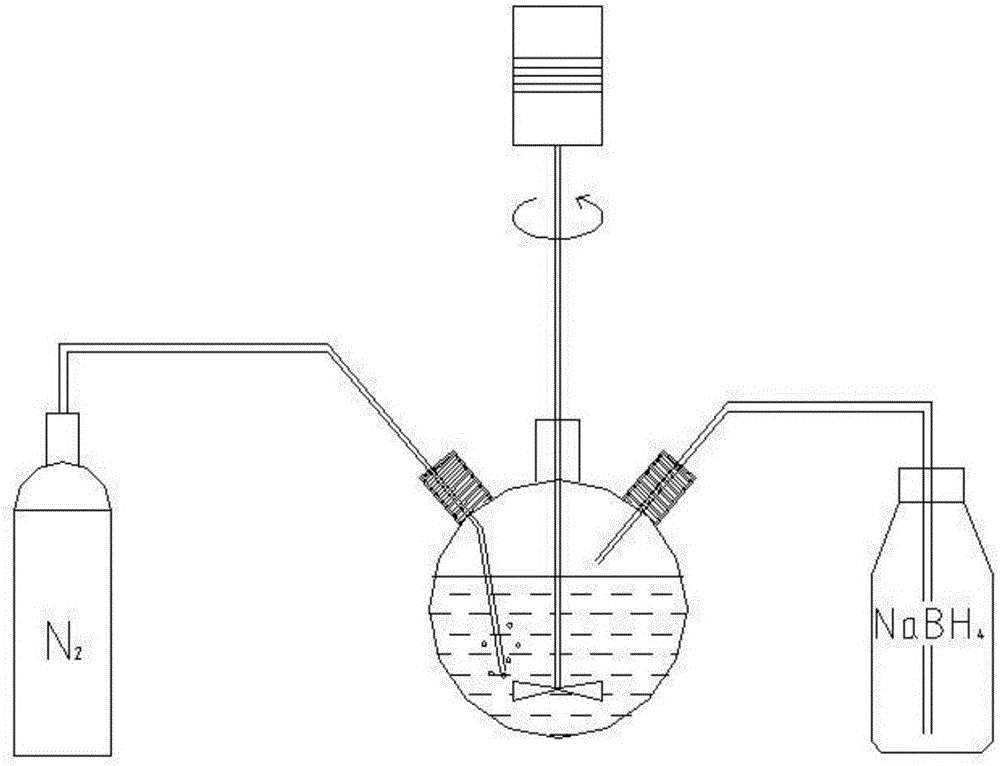

[0026] (1) Preparation of sodium carboxymethyl starch modified zero-valent nano-iron suspension

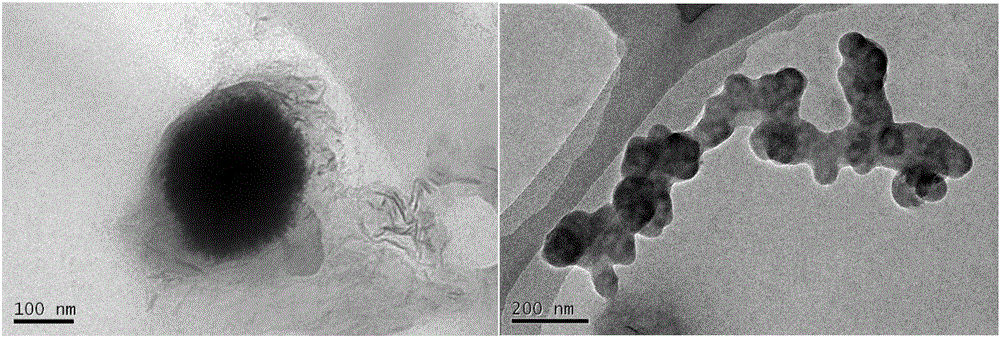

[0027] with FeSO 4 ·7H 2 FeSO with a concentration of 17.86mmol / L was prepared with O and deoxygenated deionized water 4 Solution 100mL, stirred for 5min under the condition of 300rpm / min; configuration concentration is 2.22g / L, 2.50g / L, 2.67g / L, 2.78g / L carboxymethyl starch sodium (CMS-Na) solution 150mL, respectively The two solutions were mixed and stirred evenly, and stirred for 15 minutes under nitrogen at the same speed; 4 Prepare 250 mL of NaBH with a concentration of 15.72 mmol / L and deionized water 4 solution, FeSO was pumped at a rate of 4000 μL / min with a peristaltic pump 4 and CMS-Na mixed solution, while pumping, use an electric stirrer to stir the mixed solution at a speed of 600rpm, and wait for the NaBH 4 After the solution is all pumped into the mixture, continu...

Embodiment 2

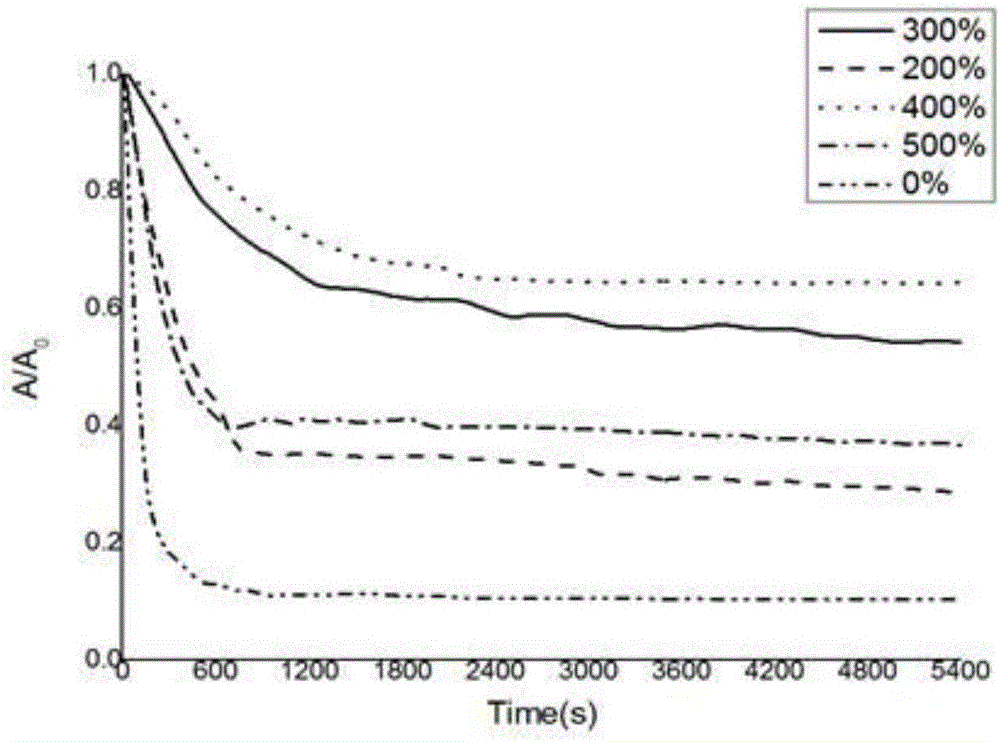

[0033] Example 2: Preparation of sodium carboxymethyl starch modified nano-iron and removal of 2,4-DCP in water

[0034] with FeSO 4 ·7H 2 FeSO with a concentration of 0.179 mol / L was prepared with O and deoxygenated deionized water 4 Solution 100mL, stir 5min under the situation of 300rpm / min; Concentration is the carboxymethyl starch sodium (CMS-Na) solution 150mL of 16g / L, 25g / L, 26g / L, mix and stir two kinds of solutions respectively, Stir with nitrogen gas at the same speed for 15 min; then use NaBH 4 Prepare 250 mL of NaBH with a concentration of 0.157 mol / L and deionized water 4 solution, FeSO was pumped at a rate of 4000 μL / min with a peristaltic pump 4 and CMS-Na mixed solution, while pumping, use an electric stirrer to stir the mixed solution at a speed of 600rpm, and wait for the NaBH 4After the solution is all pumped into the mixture, continue to stir for 15 minutes and use nitrogen to make NaBH 4 with FeSO 4 After complete mixing and reaction, a modified na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com