Composite material of nanoscale cobalt based particles and nitrogen doped carbon, synthetic method and application

A composite material, nitrogen-doped carbon technology, applied in chemical instruments and methods, electrical components, circuits, etc., can solve the problems of restricting large-scale production, poor durability, scarce output, etc., and achieve commercial large-scale production , simple operation and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] In the invention, a certain amount of ethylenediaminetetraacetic acid is added to raw materials to synthesize a composite of nano-scale cobalt-based particles / nitrogen-doped carbon, and the oxygen reduction performance is evaluated.

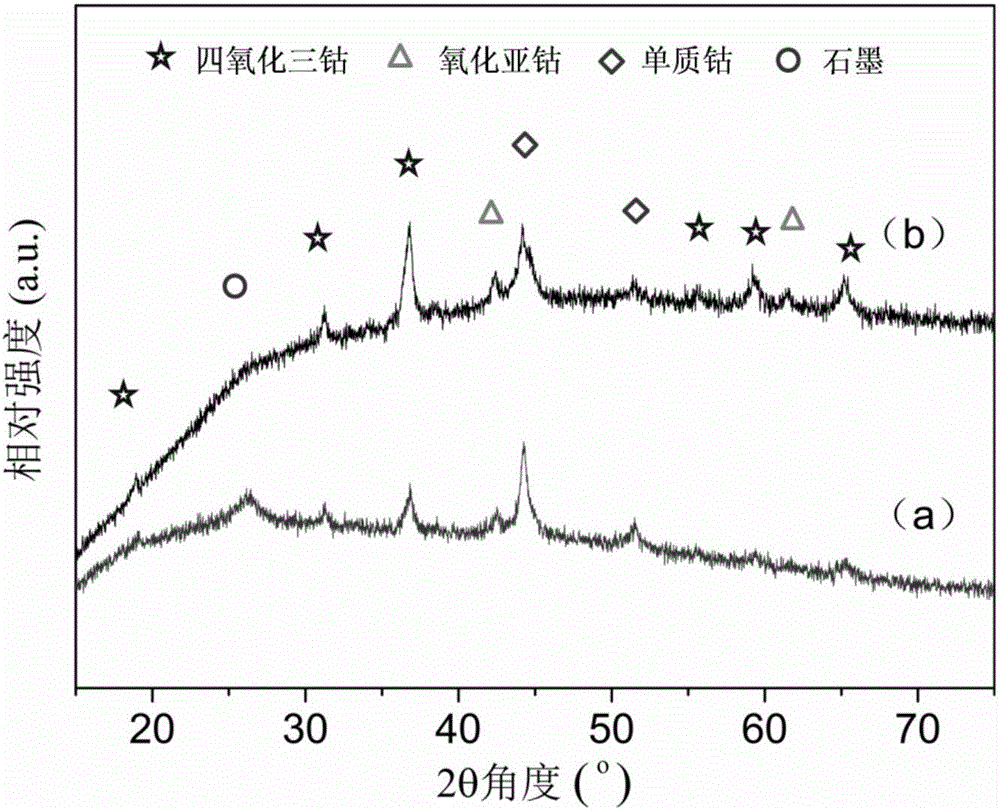

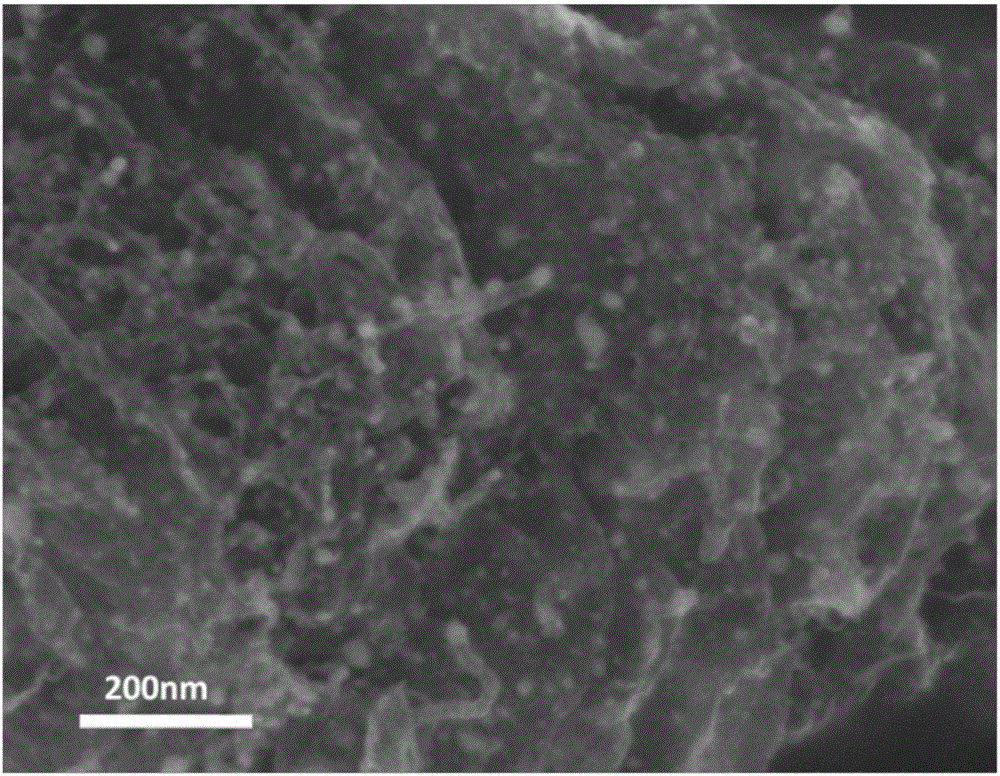

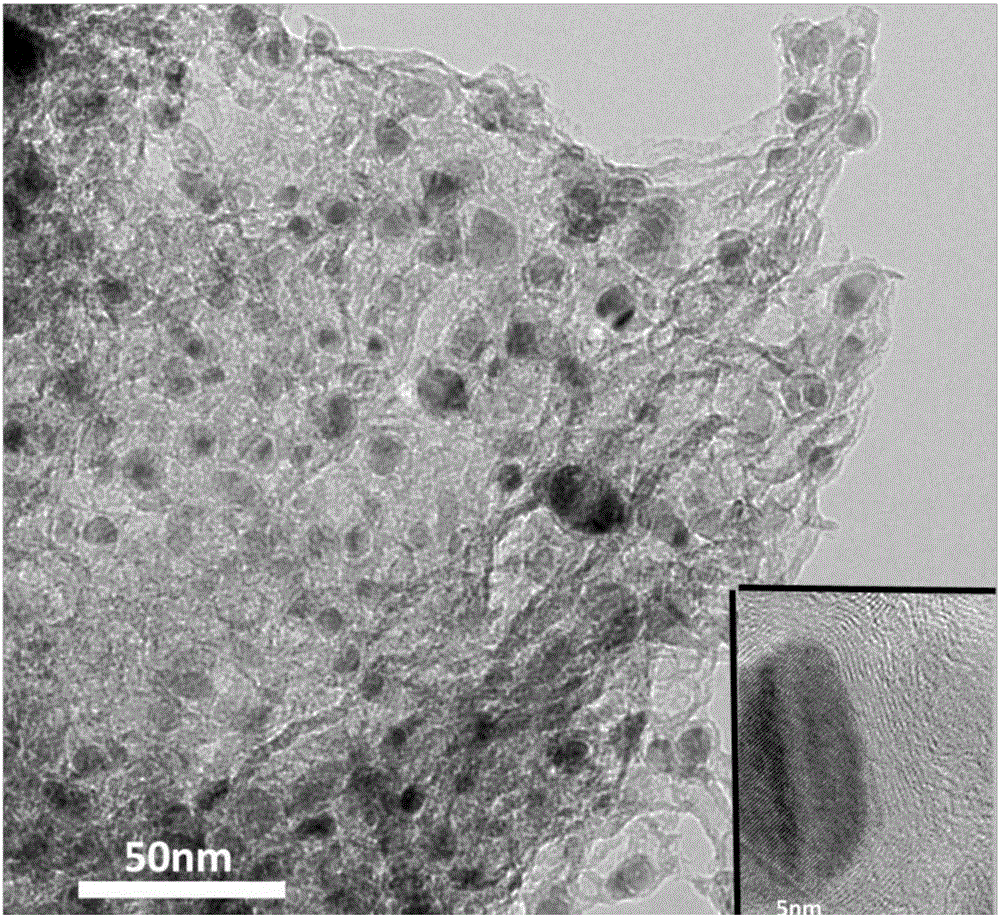

[0051] 30g of melamine and 1g of glucosamine hydrochloride were uniformly mixed in an aqueous solution to form solution A. In addition, 1 g of ethylenediamine tetraacetic acid was dissolved in the aqueous solution, and 1 g of cobalt nitrate was added thereto, and mixed uniformly to form solution B. Mix solution A and solution B evenly, heat and stir until dry. The obtained solid mixture was calcined at 800° C. for 2 h under a nitrogen atmosphere to finally obtain a composite of nano-sized cobalt-based particles and nitrogen-doped carbon. The mass content of cobalt-based particles in the composite reaches 58%, and the content of pyridine nitrogen in the product is 57% (the percentage of pyridine nitrogen in the total nitrogen), and a dense...

Embodiment 2

[0054] In the invention, a certain amount of ethylenediaminetetraacetic acid is added to raw materials to synthesize a composite of nano-scale cobalt-based particles / nitrogen-doped carbon, and the oxygen reduction performance is evaluated.

[0055] 40g of melamine and 1g of glucosamine hydrochloride were uniformly mixed in an aqueous solution to form solution A. In addition, 4 g of ethylenediaminetetraacetic acid was dissolved in the aqueous solution, and 2 g of cobalt acetate was added thereto, and mixed uniformly to form solution B. Mix solution A and solution B evenly, heat and stir until dry. The obtained solid mixture was calcined at 700° C. for 3 h under an argon atmosphere to finally obtain a composite of nano-sized cobalt-based particles and nitrogen-doped carbon. The mass content of cobalt-based particles in the composite reaches 47%, and the mass content of pyridine nitrogen in the product is 55% (the percentage of pyridine nitrogen in the total nitrogen), and a den...

Embodiment 3

[0058] In the invention, a certain amount of ethylenediaminetetraacetic acid is added to raw materials to synthesize a composite of nano-scale cobalt-based particles / nitrogen-doped carbon, and the oxygen reduction performance is evaluated.

[0059] 20g of melamine and 1g of glucosamine hydrochloride were uniformly mixed in an aqueous solution to form solution A. In addition, 0.25 g of ethylenediamine tetraacetic acid was dissolved in the aqueous solution, and 0.5 g of cobalt chloride was added thereto, and mixed uniformly to form solution B. Mix solution A and solution B evenly, heat and stir until dry. The obtained solid mixture was calcined at 600° C. for 5 h under a helium atmosphere, and finally a composite of nano-scale cobalt-based particles and nitrogen-doped carbon was obtained. The mass content of cobalt-based particles in the composite reaches 51%, and the mass content of pyridine nitrogen in the product is 51% (the percentage of pyridine nitrogen in the total nitro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com