Preparation method of high-yield high-purity MoO2 powder

A high-purity, high-yield technology, used in molybdenum oxide/molybdenum hydroxide and other directions, can solve the problems of limited large-scale preparation and production, strict control requirements, complex chemical reactions, etc., to achieve easy storage and reprocessing, and easy process. Controlled, high-purity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] High-yield, high-purity MoO proposed by the present invention 2 The preparation method of powder comprises the following steps and content:

[0027] (1) The evaporation source used is commercially available analytically pure MoO 3 powder and S powder. Among them, the evaporation source MoO 3 The grain size of the powder is between 2 and 5 μm, the evaporation source S powder is high-purity sulfur or sublimed sulfur, and the raw material MoO 3 The mass ratio of powder and S powder is controlled between 1:1 and 1:5.

[0028] (2) In the horizontal vacuum tube furnace, vertical vacuum box furnace, vertical vacuum tube furnace or well type vacuum electric furnace, the evaporation source MoO 3 Alumina ceramic crucibles of powder and S powder are placed in the heating area in the center of the furnace. Among them, the alumina ceramic crucible filled with S powder is placed above the air flow, and the MoO 3 The powdered ceramic crucible is placed under the airflow, and the...

Embodiment 1

[0033] Embodiment 1: In the horizontal vacuum tube furnace, the alumina ceramic crucible with 1g high-purity S powder and 0.5g analytically pure MoO are housed 3 The powdered alumina ceramic crucibles are respectively placed in the central heating zone of the furnace, and the distance between the two is 5cm.

[0034] Before heating, evacuate the whole system to 10 with a vacuum pump -2 Below Pa, then feed 99.99vol.% argon into the system, and repeat 3 times to get rid of the residual air in the system. Then the temperature was raised to 950°C at a rate of 30°C / min, and kept for 1 hour. During the whole heating process, keep the carrier gas flow rate at 200 sccm under the premise of continuous operation of the vacuum pump, until the temperature is naturally cooled to room temperature, then the MoO 3 High-purity MoO was obtained in a crucible of powder 2 Powder.

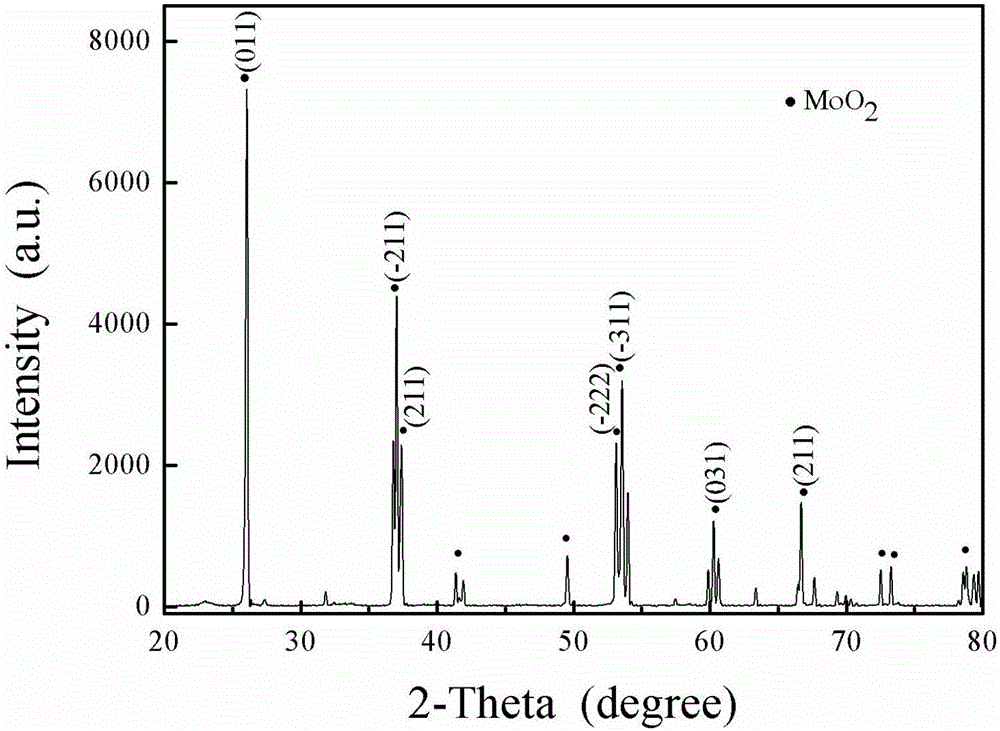

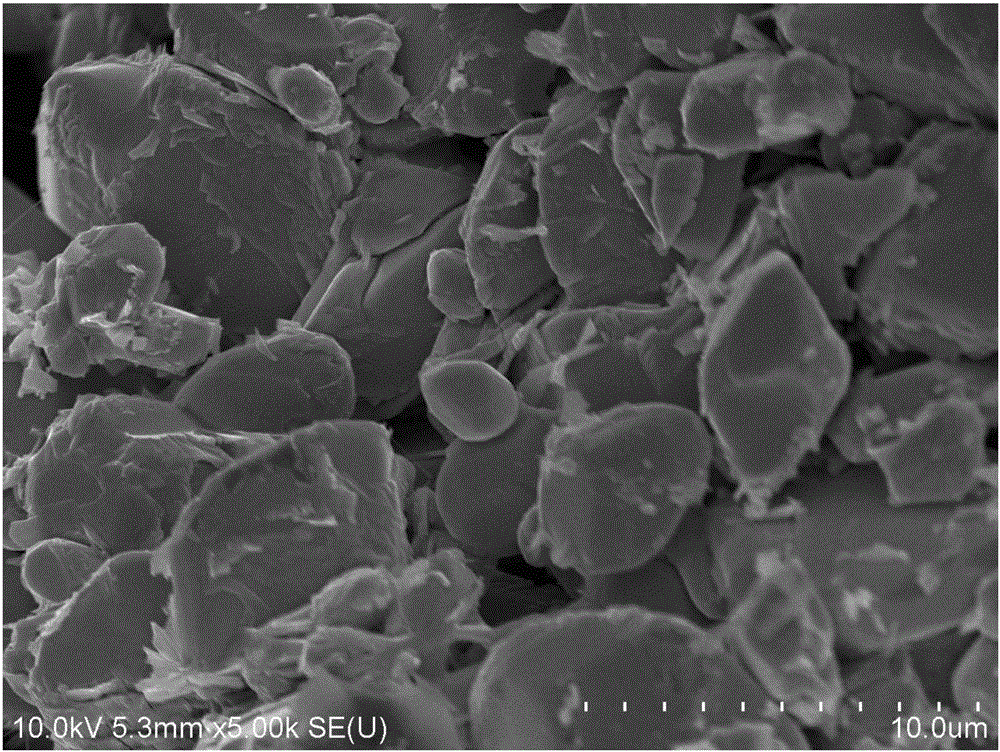

[0035] The obtained sample is crystalline MoO 2 , no impurity (see figure 1 ), showing obvious granular shape ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com