Sludge drying system and drying method achieved through shallow layer geothermal energy

A sludge system and shallow surface technology, applied in chemical instruments and methods, dehydration/drying/concentrated sludge treatment, water/sludge/sewage treatment, etc., can solve the problem of large area of solar drying and drying process Insufficient safety, high equipment operation requirements, etc., to achieve full and effective use of new energy, fast and convenient process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in further detail below in conjunction with accompanying drawing:

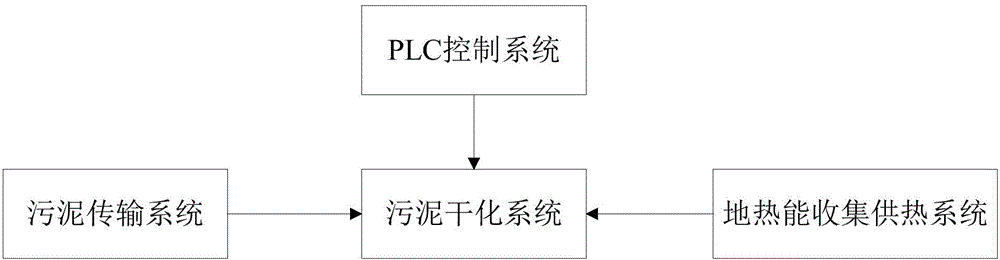

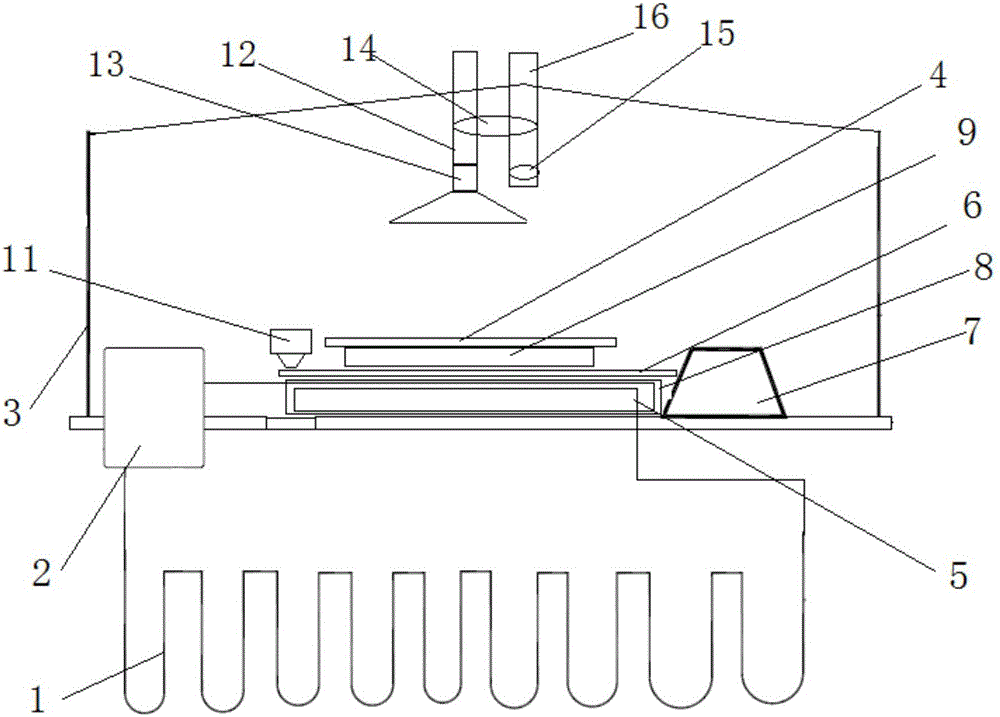

[0026] Such as figure 1 , 2 As shown, a shallow surface geothermal energy drying sludge system includes a geothermal energy collection heating system, a sludge drying system, a sludge transmission system, a PLC control system, and an exhaust system; the geothermal energy collection system includes a ground source heat pump 2 and a buried U-shaped pipe 1 buried underground; the sludge drying system includes a sludge drying room 3 and a partition 8 arranged in the sludge drying room 3, and the surroundings of the sludge drying room 3 and the partition A geothermal energy heating pipeline 5 is installed on the plate 8, and the exhaust system includes a gas transmission pipeline 12 installed on the upper end of the sludge drying room 3, a gas introduction pipeline 16 and a heat exchanger 14, and the heat exchangers 14 are respectively installed on the gas transmission pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com