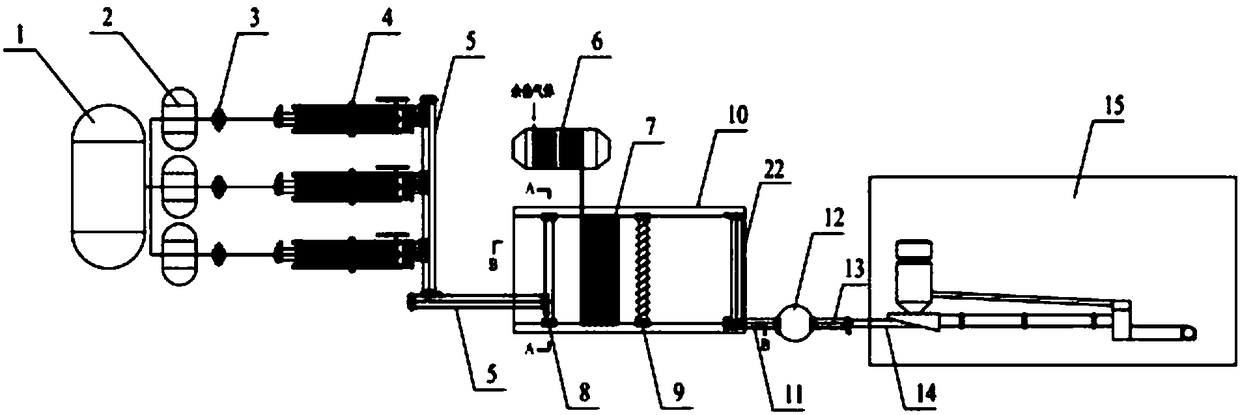

An integrated method and system for cement kiln cooperative sludge deep dehydration and sludge disposal

A deep dewatering, cement kiln technology, applied in dewatering/drying/concentrating sludge treatment, temperature-controlled sludge treatment, energy and wastewater treatment, etc. Sludge, cement clinker, etc., to avoid environmental pollution, avoid waste of resources, and realize the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

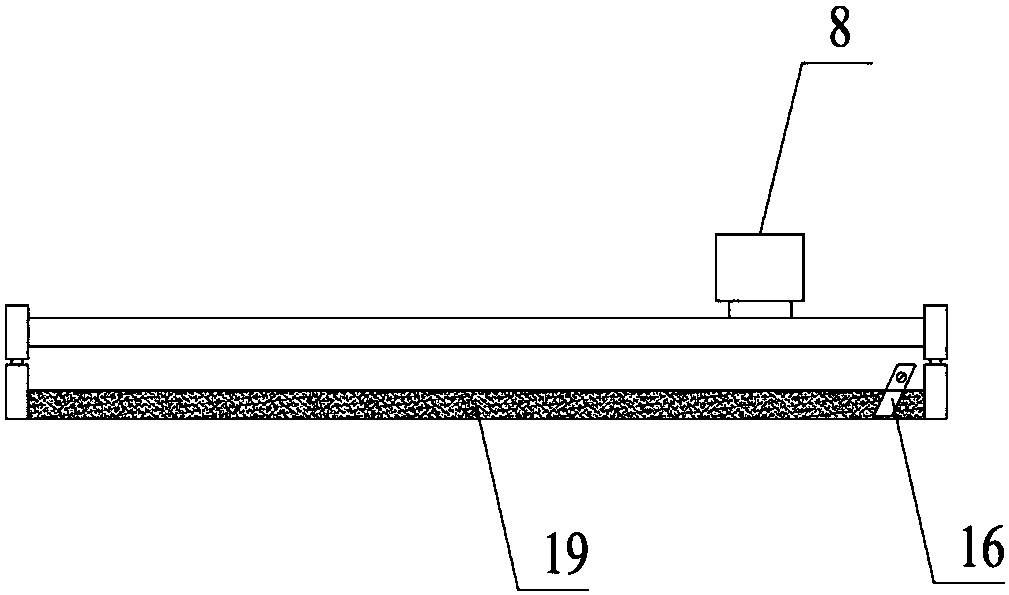

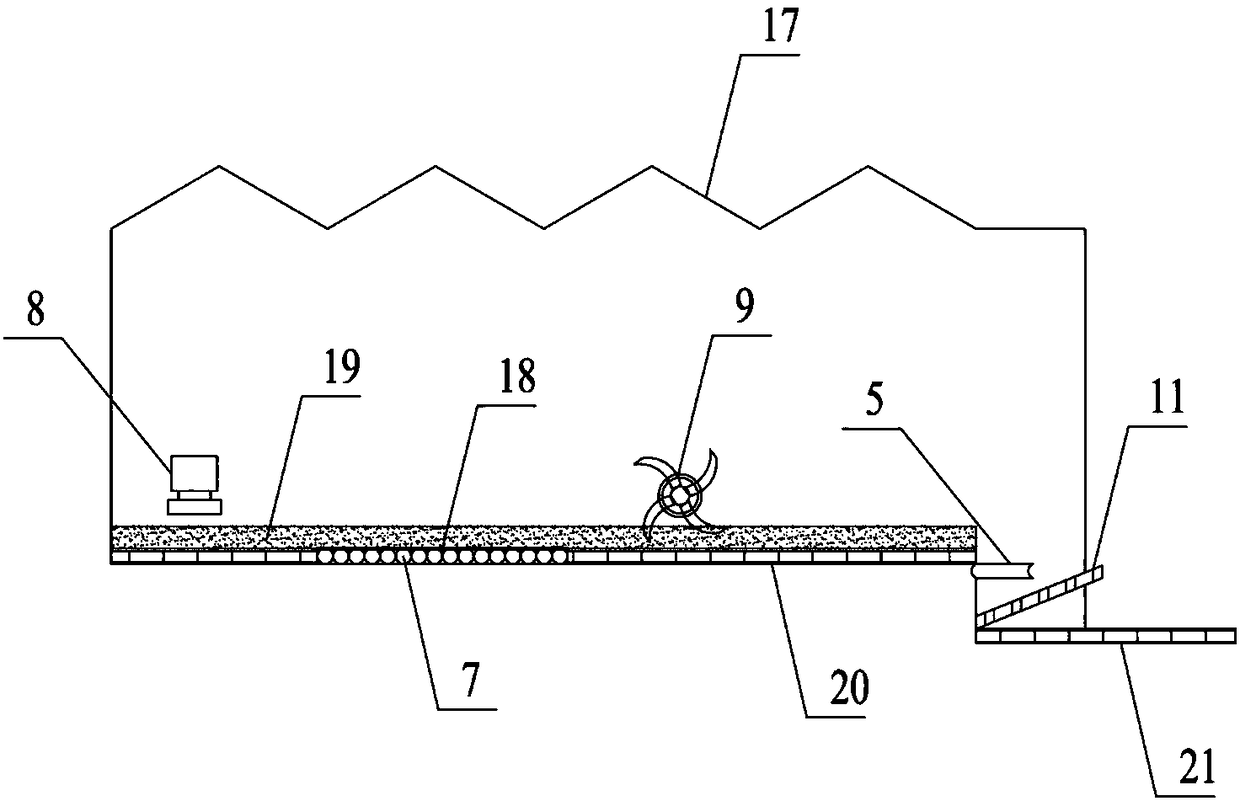

Method used

Image

Examples

Embodiment 1

[0056] 1. Dehydration pretreatment of sludge:

[0057] 1.1. Dilution and homogenization of raw sludge

[0058] The sludge from a sewage treatment plant A in Wuhan has a water content of 87% and is colloidal. The sludge from this sewage treatment plant A is pumped into the homogenizing mixing tank (effective volume is 150m 3 ), add water, in addition to adding tap water for the first homogenization and stirring, add the tail water produced by the mechanical filter press each time after homogenization and stirring, use a mixer (size Φ900×1545mm, stirring power 8.5kW) to stir and dilute To obtain fluid mud, the mud properties are uniform, and its concentration is 10%, where the concentration is the ratio of the quality of the dry matter in the mud to the total mass of the mud.

[0059] 1.2. Conditioning and modification of mud:

[0060] Pump the mud into each modified mixing tank (the effective volume is 24m 3 ), the dosing device in each modified mixing tank adds a compound c...

Embodiment 2

[0079] 1. Dehydration pretreatment of sludge:

[0080] 1.1. Dilution and homogenization of raw sludge

[0081] The moisture content of the sludge from a sewage treatment plant B in Wuhan City is 84%, and it is colloidal. The sludge from the sewage treatment plant B is pumped into the homogenization mixing tank (effective volume is 150m 3 ), add water, in addition to adding tap water for the first homogenization and stirring, add the tail water produced by the mechanical filter press each time after homogenization and stirring, use a mixer (size Φ900×1545mm, stirring power 8.5kW) to stir and dilute To obtain fluid mud, the mud properties are uniform, and its concentration is 10%.

[0082] 1.2. Conditioning and modification of mud:

[0083] Pump the mud into each modified mixing tank (the effective volume is 24m 3 ), the dosing device in each modified mixing tank adds a compound conditioner to the mud to condition and modify the mud. The compound conditioner is one of acrylam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com