2-functionality-degree makrolon urethane acrylate and preparation method and application thereof

A technology of urethane acrylate and isocyanate ethyl acrylate, applied in the field of materials, can solve the problems of difficult control of the production process, many steps in the reaction process, cumbersome and other problems, and achieve the effects of easy control, reduction of reaction steps and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

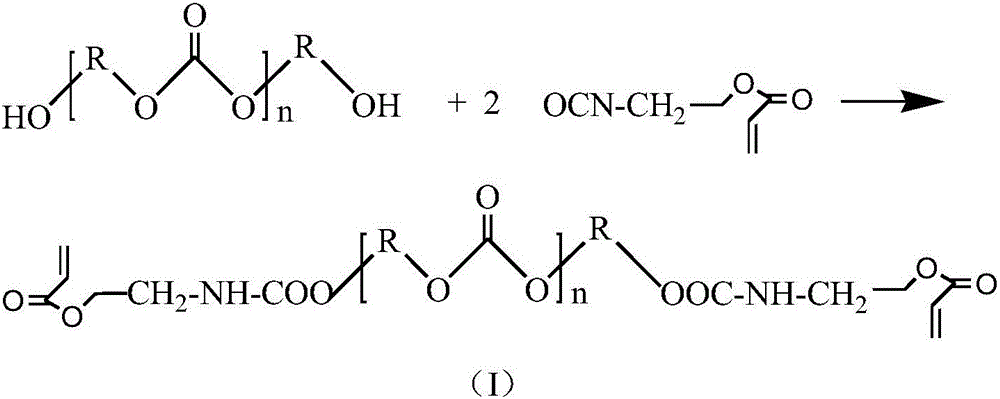

Method used

Image

Examples

Embodiment 1

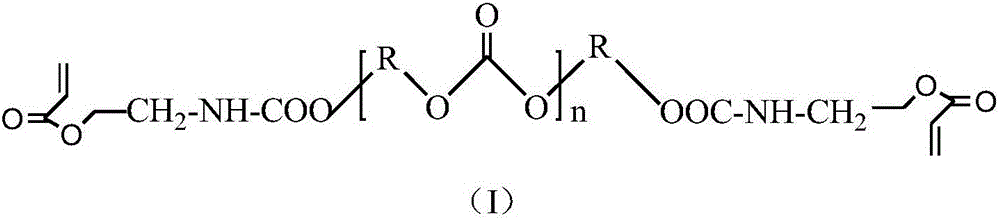

[0036] In a 1000mL four-necked flask, 500 grams of polycarbonate diol (UBE Ube Industrial Co., Ltd. UH-50, molecular weight 500), 282 grams (2mol) of isocyanate ethyl acrylate, 0.09 grams of catalyst dibutyltin dilaurate, and polymerization inhibition Add 0.9 g of p-hydroxyanisole, slowly heat up to 80°C-85°C for 0.5-4 hours, heat-retain and react for 3-5 hours, and then discharge the material to obtain a bifunctional polycarbonate urethane acrylate with the structure shown in the following formula.

[0037]

[0038] R is: -CH 2 CH 2 CH 2 CH 2 CH 2 CH 2 -, that is, the diol monomer in the polycarbonate diol is 1,6-hexanediol;

[0039] n=(500-118) / 144=2.6528.

Embodiment 2

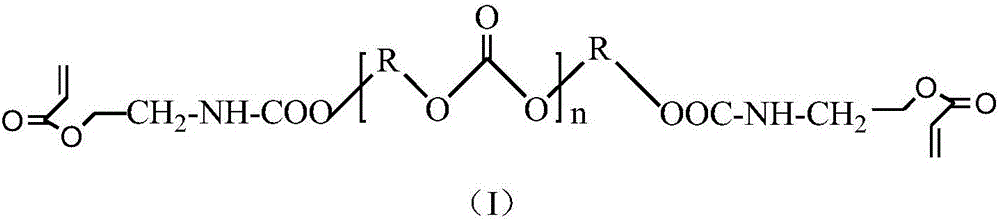

[0041] In a 1000mL four-necked flask, 500 grams of polycarbonate diol (UBE Ube Industrial Co., Ltd. UH-100, molecular weight 1000), 141 grams of isocyanate ethyl acrylate (1mol), 0.1 gram of dibutyltin dilaurate as a catalyst, and polymerization inhibition Add 0.7 g of p-hydroxyanisole, slowly heat up to 80°C-85°C for 0.5-4 hours, heat-retain and react for 3-5 hours, and then discharge the material to obtain a bifunctional polycarbonate urethane acrylate with the structure shown in the following formula.

[0042]

[0043] R is: -CH 2 CH 2 CH 2 CH 2 CH 2 CH 2 -, that is, the diol monomer in the polycarbonate diol is 1,6-hexanediol;

[0044] n=(1000-118) / 144=6.1250.

Embodiment 3

[0046] In a 1000mL four-necked flask, 500 grams of polycarbonate diol (UBE Ube Industrial Co., Ltd. UH-200, molecular weight 2000), 70.5 grams of isocyanate ethyl acrylate (0.5mol), 0.1 gram of dibutyltin dilaurate as a catalyst, and Polymerizing agent p-hydroxyanisole 0.6 g, slowly heating up to 80°C-85°C for 0.5-4 hours, heat-retaining reaction for 3-5 hours, and then discharging to prepare bifunctional polycarbonate urethane acrylate with the structure shown in the following formula.

[0047]

[0048] R is: -CH 2 CH 2 CH 2 CH 2 CH 2 CH 2 -, that is, the diol monomer in the polycarbonate diol is 1,6-hexanediol;

[0049] n=(2000-118) / 144=13.0694.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com