A kind of phenolic glass fiber prepreg with light color and high-quality surface effect and preparation method thereof

A phenolic glass fiber prepreg and surface effect technology, which is applied in the field of phenolic glass fiber prepreg and its preparation, functionally modified phenolic glass fiber prepreg and its preparation, can solve the problem of deep color, low surface quality, poor shading effect, etc. problem, to achieve the effect of uniform color, good effect and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

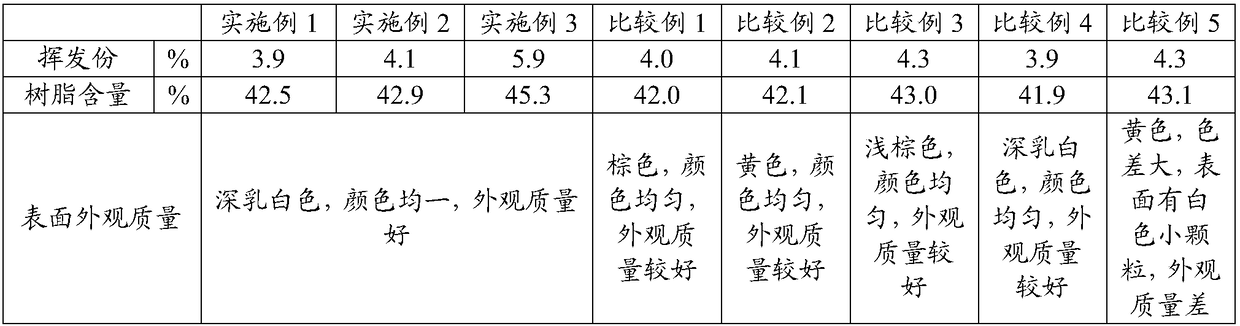

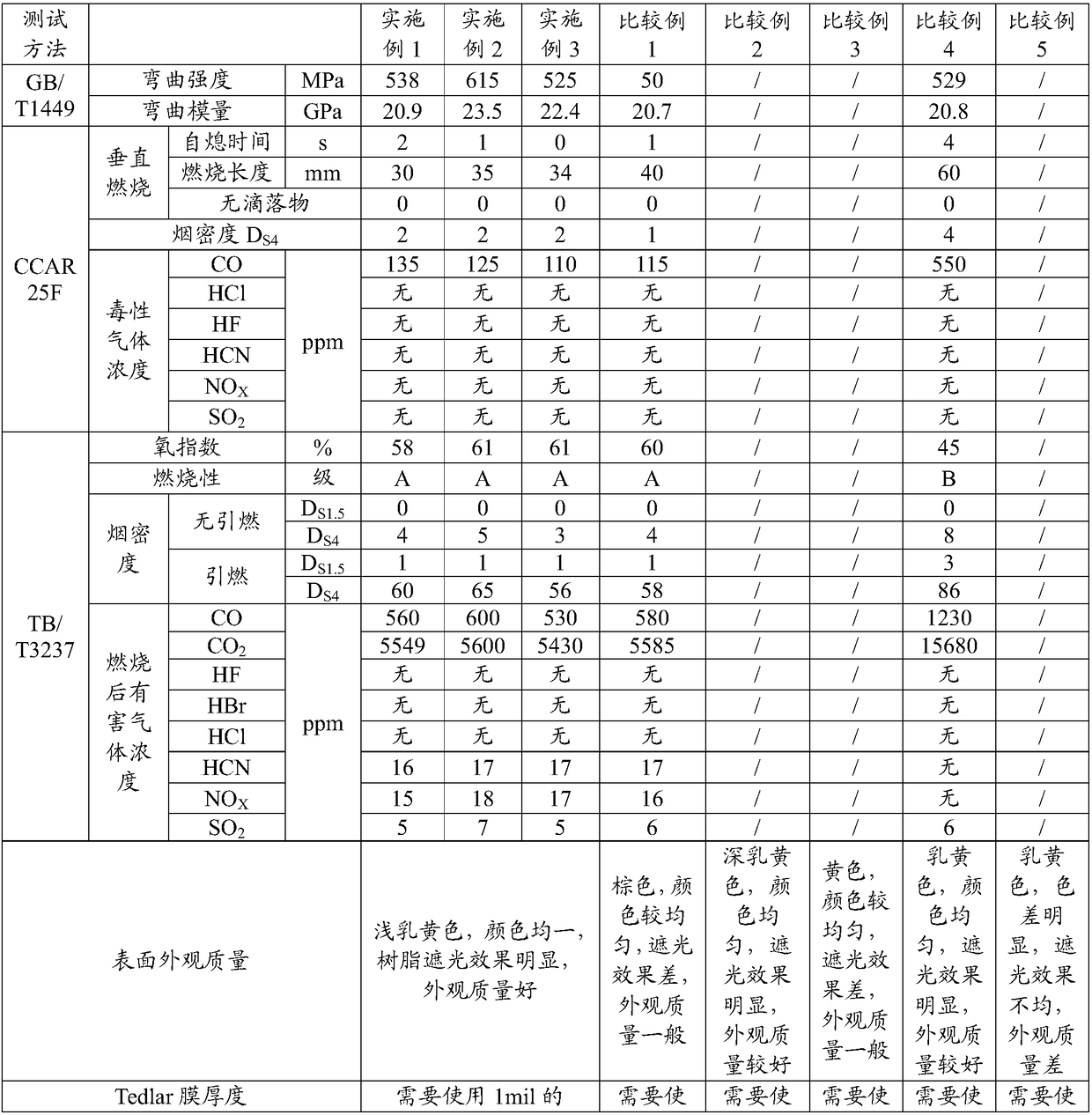

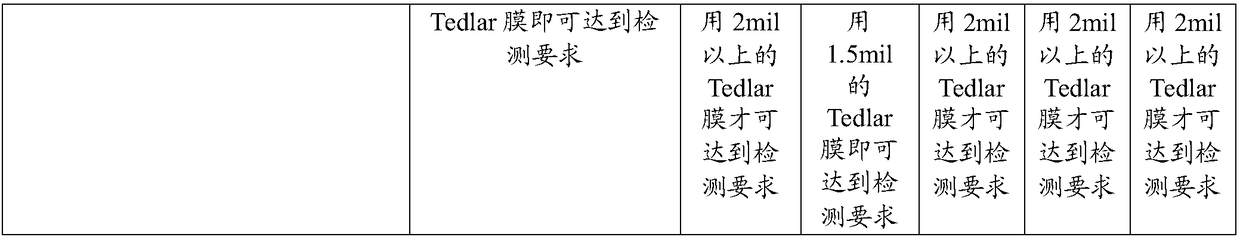

Examples

Embodiment 1

[0033] 1) In a reaction kettle with an effective volume of 200L, add phenol and formaldehyde solution in sequence at a molar ratio of 1:1.8, stir at a speed of 100r / min, and add Ba(OH) 2 ·8H 2 O to adjust the pH value to 8, then slowly raise the temperature to about 95°C and react at a constant temperature for more than 2 hours, then vacuum dehydrate for more than 1 hour, add phosphoric acid to neutralize until the pH value reaches 7, precipitate and cool to room temperature, and the obtained is the basic phenolic resin , keep 100kg in the kettle for standby;

[0034] 2) Add 1kg of titanium dioxide, 1kg of polymerized ammonium phosphate and 5kg of E51 epoxy resin into a 10L reaction kettle with heating function, stir at a speed of 300r / min, then heat to 90°C and keep it warm for more than 30min, then move into three The roller grinder stops after grinding 2 times, and it is used for standby;

[0035]3) add 50kg ethanol in step 1) gained base phenolic resin, under the stirrin...

Embodiment 2

[0042] 1) In a reaction kettle with an effective volume of 200L, add phenol and formaldehyde solution in sequence at a molar ratio of 1:1.8, stir at a speed of 100r / min, and add Ba(OH) 2 ·8H 2 O to adjust the pH value to 8, then slowly raise the temperature to about 95°C and react at a constant temperature for more than 2 hours, then vacuum dehydrate for more than 1 hour, add a certain amount of phosphoric acid to neutralize until the pH value reaches 7, precipitate and cool to room temperature, and the obtained is the basis Phenolic resin, keep 100kg in the kettle for subsequent use;

[0043] 2) Add 1kg of titanium dioxide, 1kg of polymerized ammonium phosphate and 5kg of E51 epoxy resin into a 10L reaction kettle with heating function, stir at a speed of 300r / min, then heat to 90°C and keep it warm for more than 30min, then move into three The roller grinder stops after grinding 2 times, and it is used for standby;

[0044] 3) Add 50kg ethanol in step 1) gained basic pheno...

Embodiment 3

[0051] 1) In a reaction kettle with an effective volume of 200L, add phenol and formaldehyde solution in sequence at a molar ratio of 1:1.8, stir at a speed of 100r / min, and add Ba(OH) 2 ·8H 2 O to adjust the pH value to 8, then slowly raise the temperature to about 95°C and react at a constant temperature for more than 2 hours, then vacuum dehydrate for more than 1 hour, add a certain amount of phosphoric acid to neutralize until the pH value reaches 7, precipitate and cool to room temperature, and the obtained is the basis Phenolic resin, keep 100kg in the kettle for subsequent use;

[0052] 2) Add 1kg of titanium dioxide, 1kg of polymerized ammonium phosphate and 5kg of E51 epoxy resin into a 10L reaction kettle with heating function, stir at a speed of 300r / min, then heat to 90°C and keep it warm for more than 30min, then move into three The roller grinder stops after grinding 2 times, and it is used for standby;

[0053] 3) Add 50kg ethanol in step 1) gained basic pheno...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com