Method for preparing dihydro-dehydro-di(coniferyl alcohol)glucoside (HMZG) through biotransformation

A technology for coniferyl glycoside and biotransformation, applied in the biological field, can solve the problems of high cost, difficult to prepare in large quantities, pollute the environment, etc., and achieve the effects of low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

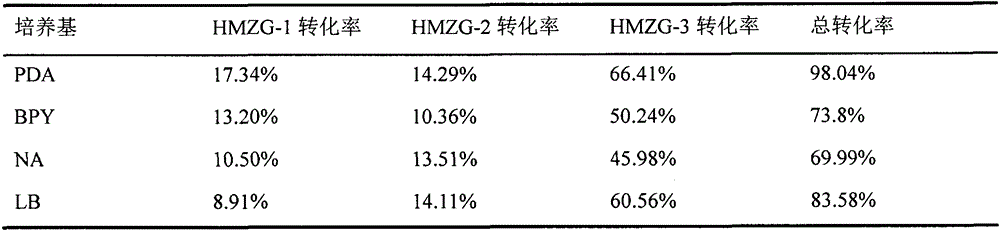

[0020] Preparation of HMZG-1, HMZG-2 and HMZG-3 (cultured with PDA medium)

[0021] The slant (i.e. bacterial classification) was inoculated in the shake flask seed medium, cultivated for 24 hours at 26°C, and the shake flask rotating speed was 180r / min; access the PDA transformation medium (potato 200g / L, KH 2 PO 4 3g / L, MgSO 4 0.73g / L, VB 1 10mg / L, sucrose 25g / L, pH 7.0), while adding 0.2mg / mL of substrate, at 26°C, the rotation speed was 180r / min for 72h. The conversion rate of the three conversion products HMZG-1, HMZG-2 and HMZG-3 was detected by HPLC. The detection condition was acetonitrile-water gradient elution, and the elution program was: 0-10min 15%-24% acetonitrile, 10-25min 24%-30% acetonitrile, 30% acetonitrile for 25-30min; flow rate 1.0mL / min; column temperature 25°C; detection wavelength 203nm; injection volume 10μL. The retention times of HMZG-1, HMZG-2 and HMZG-3 were 12.306min, 14.817min and 15.359min respectively, and the conversion rates were 17.3...

Embodiment 2

[0023] Preparation of HMZG-1, HMZG-2 and HMZG-3 (cultured with BPY medium)

[0024] The slant (i.e. bacterial classification) was inoculated in the shake flask seed medium, cultivated at 26°C for 24 hours, and the shake flask rotating speed was 180r / min; insert BPY transformation medium (beef extract 5.0g / L) by 2% inoculum , peptone 10.0g / L, yeast extract 5.0g / L, NaCl 5.0g / L, glucose 10.0g / L, pH 7.0), add 0.2mg / mL substrate at the same time, at 26°C, the speed is 180r / min Fermentation and culture under the conditions for 72h. The conversion rates of the three conversion products HMZG-1, HMZG-2 and HMZG-3 were detected by HPLC. The detection conditions were the same as in Example 1, and the conversion rates were 13.20%, 10.36%, and 50.24%, respectively.

Embodiment 3

[0026] Preparation of HMZG-1, HMZG-2 and HMZG-3 (cultured with NA medium)

[0027] The slant (i.e. bacterial classification) was inoculated in the shake flask seed medium, cultivated at 26°C for 24 hours, and the shake flask rotating speed was 180r / min; insert NA transformation medium (beef extract 3.0g / L) by 2% inoculum , peptone 10.0g / L, NaCl 5.0g / L, agar 18.0g / L, pH 7.0), and 0.2mg / mL substrate was added at the same time, and the fermentation was carried out at 26°C and the rotation speed was 180r / min for 72h. The conversion rates of the three conversion products HMZG-1, HMZG-2 and HMZG-3 were detected by HPLC. The detection conditions were the same as in Example 1, and the conversion rates were 10.50%, 13.51%, and 45.98%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com