Equipment and method for online pelletizing of dedusting dust

A kind of equipment and pelletizing technology, which is applied in the field of online pelletizing equipment for dust removal, can solve the problems of low service life of cloth bags and keels, inconvenient handling and utilization, and easy scattering of dust removal dust, etc., and achieve the effect of saving procedures, saving manpower, and simple procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

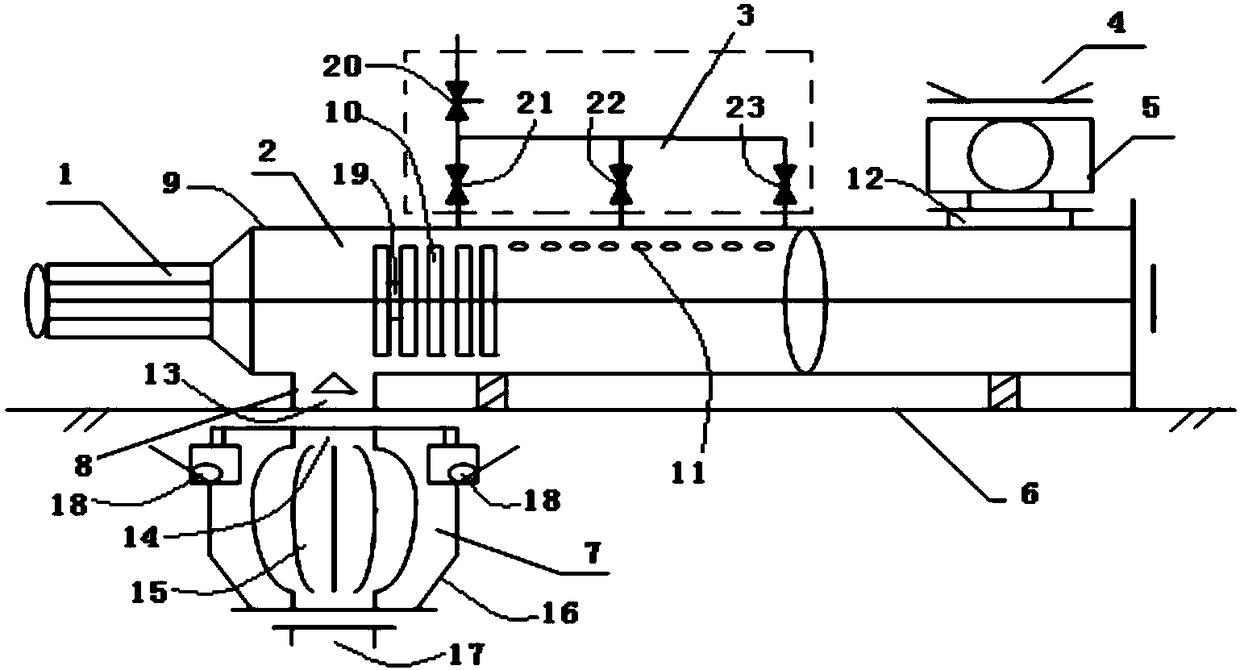

[0020] Below with the accompanying drawings ( figure 1 ) to illustrate the present invention.

[0021] figure 1 It is a structural schematic diagram of the dedusting online pelletizing equipment implementing the present invention. Such as figure 1 As shown, the dedusting ash online pelletizing equipment includes a mixer 2, and the mixer inlet 12 of the mixer 2 is connected to the ash silo 4, and the ash silo 4 has an online connection to the iron and steel smelting dust collector. Connection interface, the mixer outlet 13 of the mixer 2 is connected to the pelletizer 7 . The feed port 14 of the pelletizer of the pelletizer 7 corresponds to the discharge port 13 of the mixer, and the discharge port 13 of the mixer is provided with a hopper 8, and the hopper 8 is connected to the pelletizer. Material mouth 14. The pelletizing machine discharge port 17 of the pelletizing machine 7 is an interface connected with a cloth bag, and the cloth bag is used for collecting dedusted a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com