Communication method and data interaction device for robots

A data interaction and communication method technology, applied in the field of communication control, can solve the problems of poor versatility and high cost of data interaction methods, and achieve the effect of simple wiring and ensuring correctness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

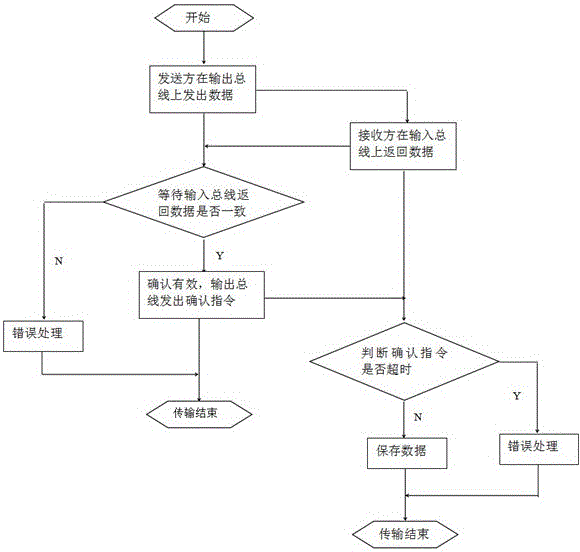

[0033] like figure 1 Shown is a flow chart of the communication method of the present invention, a communication method for a robot, comprising the following steps:

[0034] Step 1: The sender sends a data signal on the output bus, and the data signal is composed of command + data. The 16-bit output bus can be separated into two 8-bit data signals, and the signals can be respectively the agreed command and the subsequent data, and the instruction is a control instruction of the robot;

[0035] Step 2: The receiver receives the data sent on the output bus, and returns the data to the sender through the input bus;

[0036] Step 3: The sender receives the data returned by the input bus, and compares whether it is consistent with the currently sent data; if the returned data is consistent with the currently sent data, it is confirmed as valid data, and the output bus sends a confirmation command; if the returned data is consistent with the current If the sent data is inconsisten...

Embodiment 2

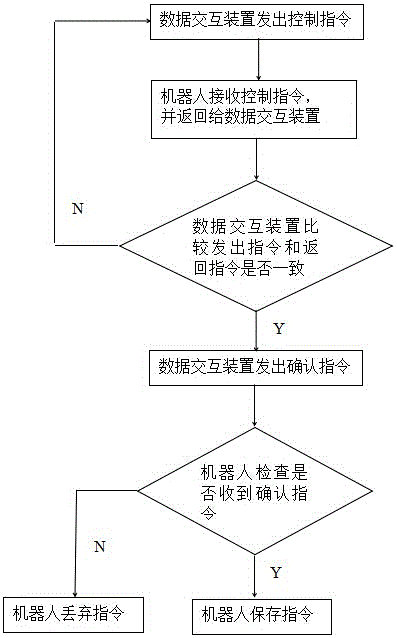

[0040] A communication system for a robot, characterized in that it includes a data sending module, and the sender sends data to the data receiving and feedback module on the output bus through the data sending module;

[0041] Data receiving and feedback module, the receiver receives the data sent on the output bus through the data receiving and feedback module, and returns the data to the sender through the input bus;

[0042] Data verification module, the sender receives the data returned by the input bus, and compares whether the data returned by the input bus is consistent with the currently sent data through the data verification module; if the returned data is consistent with the currently sent data, it is confirmed as valid data, The output bus sends a confirmation command; if the returned data is inconsistent with the currently sent data, it is confirmed as invalid data, and the output bus sends out error processing;

[0043] Data confirmation module, the receiver rec...

Embodiment 3

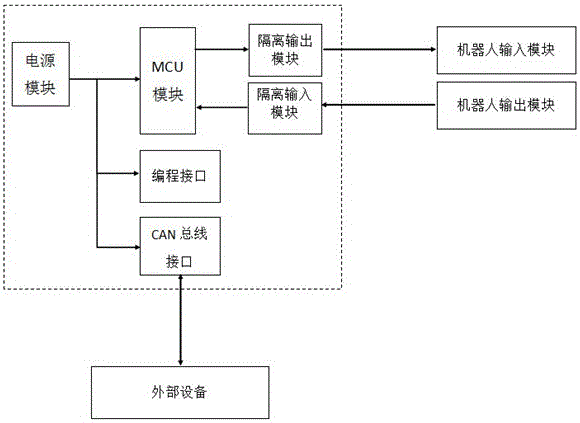

[0046] like figure 2Shown is a diagram of the data interaction device of the present invention, a data interaction device for robots, including a power supply module, the power supply module is a DC power supply, capable of stepping down and stabilizing the forward voltage, and its input voltage range is 20 ~28V; MCU module, based on embedded industrial-grade ARM processor STM32F103, the processor has 48 general-purpose GPIOs, 32 of which are selected and divided into two groups to connect to the isolated input module and isolated output module respectively. The MCU module controls The entire process of data interaction, including the selection of transmission objects, the initiation of transmission behavior, the storage of transmission data, the targeted conversion of transmission data, and the verification of transmission data, this module ensures the accuracy of the entire data interaction process; the isolation input module and An isolated output module, the power supply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com