Porous composite electrode and preparation method therefor

A composite electrode and porous metal technology, which is applied in hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, battery electrodes, etc., can solve the problems of high cost and difficulty in large-scale production, and achieve high utilization rate, charge and ion The effect of short transmission distance and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Example 1 Preparation of porous metal body

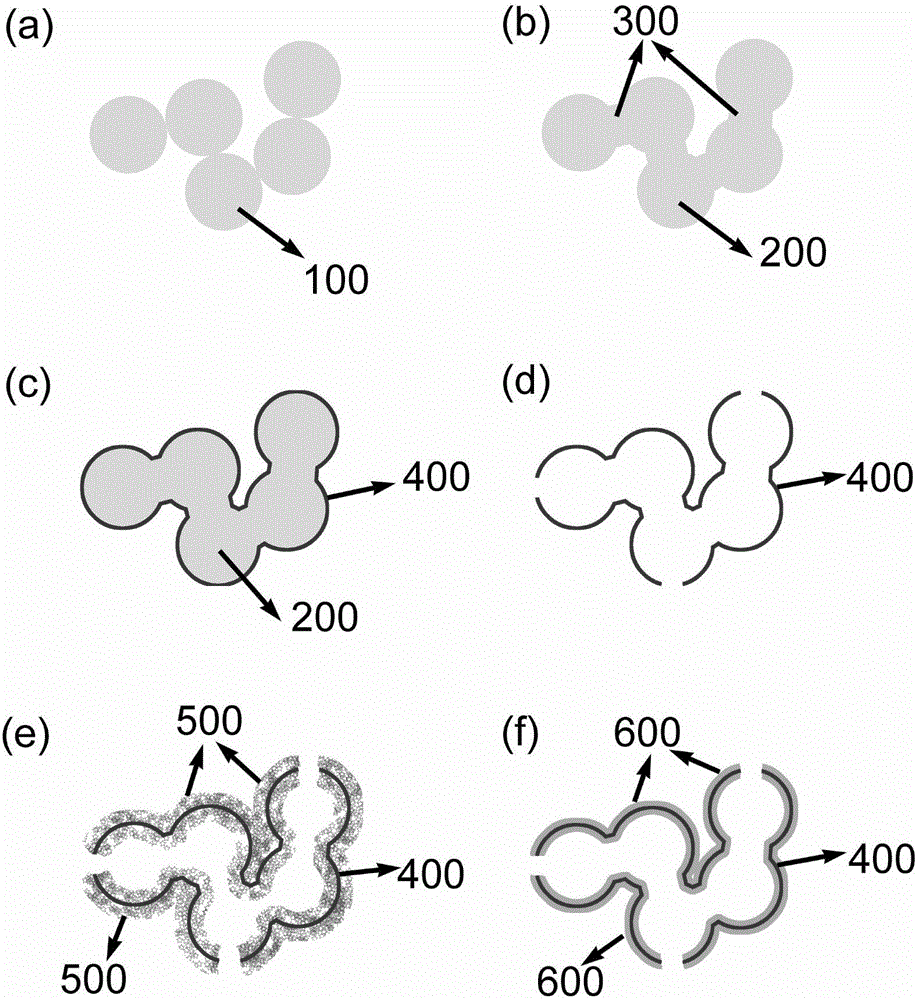

[0069] In this embodiment, the method for preparing a porous metal body includes the following steps:

[0070] Copper powder is used as template particles, and porous metal is prepared by electroplating nickel method:

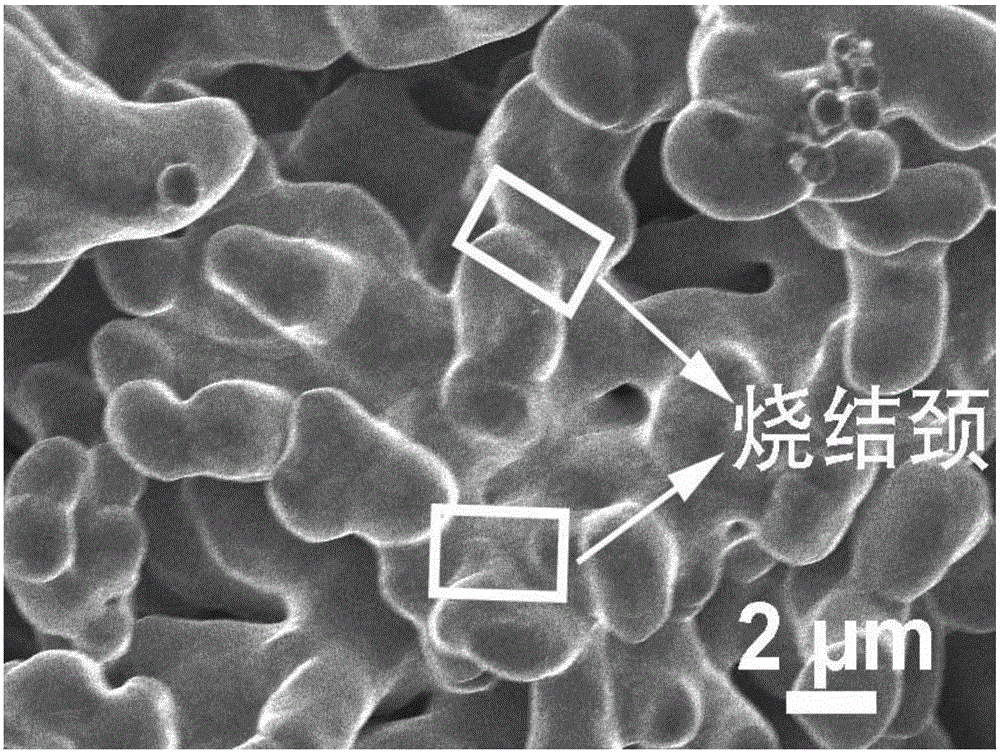

[0071] (1) Place commercial electrolytic copper powder with a particle size of about 50nm to 100 μm on a graphite plate of 3 cm×10 cm, and prepare a layer of electrolytic copper powder with a thickness of 1 μm to 100 μm using an adjustable membrane device. The graphite plate loaded with the electrolytic copper powder layer was placed in a vacuum tube furnace, vacuumed, heat-treated and sintered at 700° C. to 900° C. for 2 hours, and cooled naturally.

[0072] (2) Put the copper sheet template prepared in step (1) as the cathode into the nickel plating solution and fully soak it, and the nickel sheet as the anode, at a current density of 5mA cm -2 Electroplating is carried out for 1.5 to 2 hours under certain...

Embodiment 2

[0080] Example 2 Preparation of metallic nickel porous body MnO x Compound electrode

[0081] The preparation of the metal nickel porous body MnO in this embodiment x The method for compound electrode, comprises the steps:

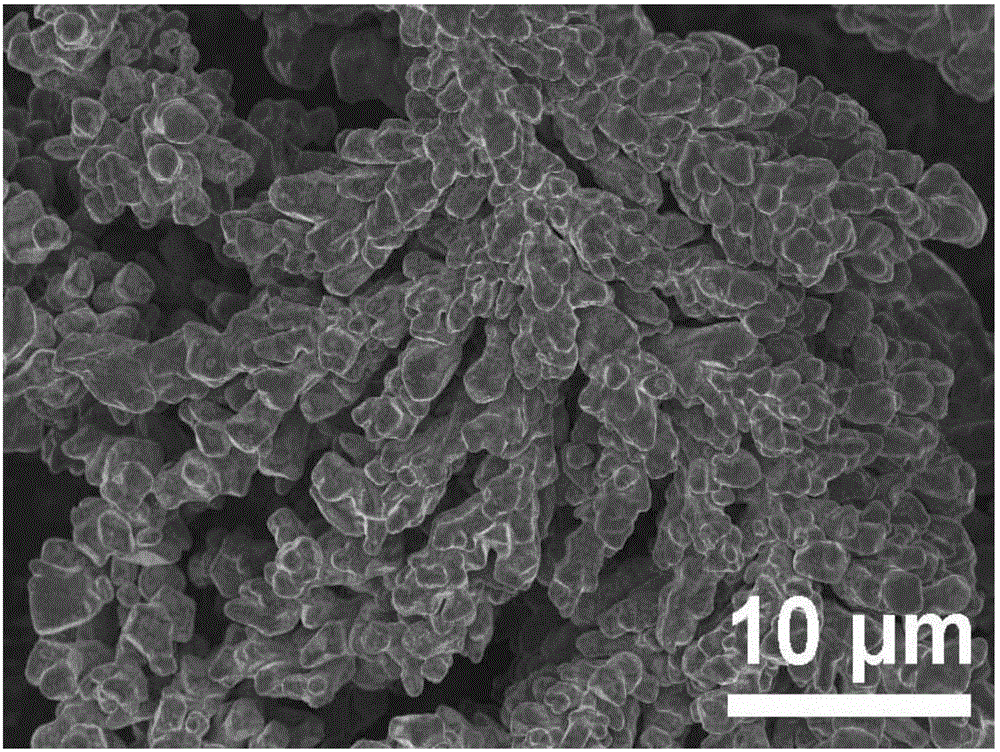

[0082] (1) In this experiment, a 20 μm electrolytic copper powder layer was prepared using an adjustable membrane device. The heat treatment and sintering process is carried out at 900°C to obtain a connected electrolytic copper powder template.

[0083] (2) Put the copper sheet template prepared in step (1) as the cathode into the nickel plating solution and fully soak it, and the metal nickel sheet as the anode, at a current density of 2mA cm -2 Electroplating is carried out for 1.5 to 2 hours under certain conditions.

[0084] (3) The material obtained in step (2) is fully cleaned, with 140g L -1 Sodium persulfate, 250g L -1 Ammonium sulfate, 140g L -1 The chemical copper-removing solution prepared by sodium hydroxide is subjected to copper-remov...

Embodiment 3

[0092] Example 3 Preparation of metallic nickel porous body NiCo 2 o 4 Compound electrode

[0093] The preparation of metal nickel porous body NiCo in this embodiment 2 o 4 The method for compound electrode, comprises the steps:

[0094] (1) In this experiment, a 20 μm electrolytic copper powder layer was prepared using an adjustable membrane device. The heat treatment and sintering process is carried out at 900°C to obtain a connected electrolytic copper powder template.

[0095] (2) Put the copper sheet prepared in step (1) as the cathode into the SN nickel plating solution and fully soak it, and the metal nickel sheet as the anode, at a current density of 2mA cm -2 Electroplating is carried out for 1.5 to 2 hours under certain conditions.

[0096] (3) The material obtained in step (2) is fully cleaned, with 140g L -1 Sodium persulfate, 250g L -1 Ammonium sulfate, 140g L -1 The chemical copper-removing solution prepared by sodium hydroxide is subjected to copper-rem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com