Gallium nitride-based transistor with high electron mobility

A high electron mobility, gallium nitride-based technology, applied in the field of gallium nitride-based high electron mobility transistors, can solve the problems of output power drop, charge imbalance of superjunction GaN HEMT, etc., to improve charge imbalance, improve current Collapse effect, effect of suppressing current collapse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

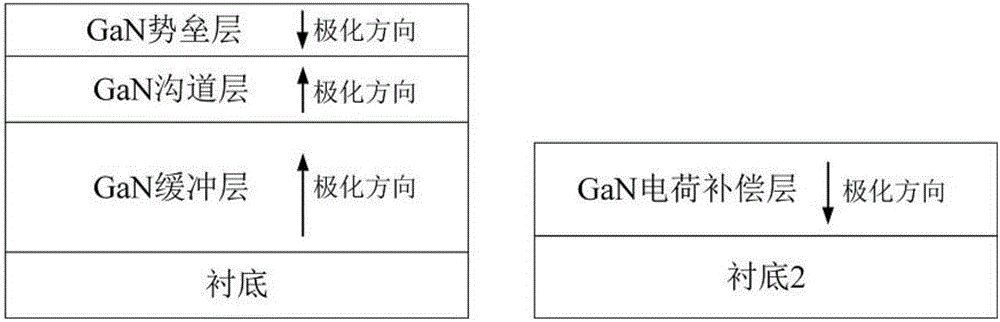

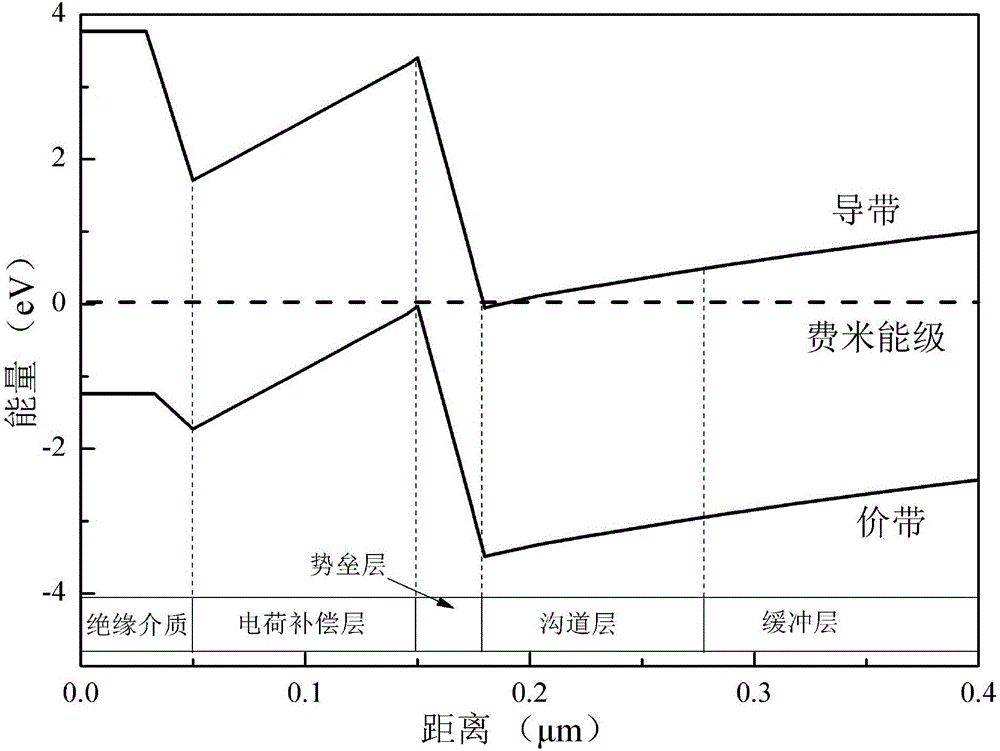

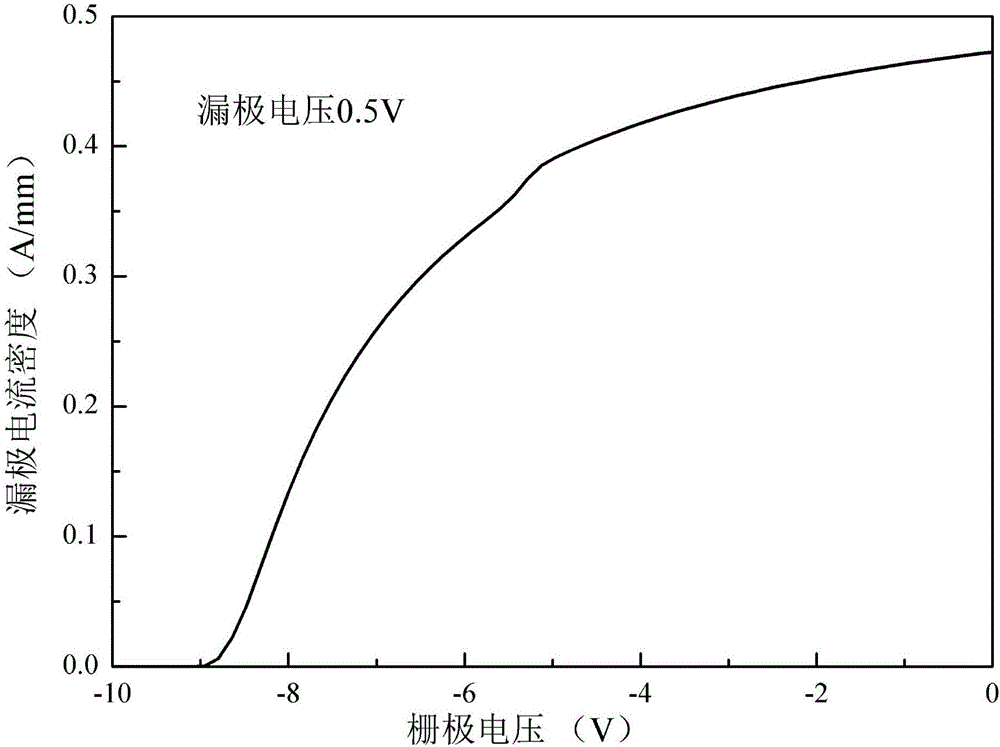

[0037] Figure 4A ~ Figure 4G It is a schematic diagram of the fabrication process of the device structure proposed by the present invention. Figure 4A In preparation for device epitaxy, the GaN buffer layer 102 and the GaN channel layer 103 are prepared on the substrate 101, and their polarization directions are both upward, and the GaN barrier layer 104 is prepared on the substrate 1011, and their polarization direction is also upward. Figure 4B, the GaN channel layer 103 and the GaN barrier layer 104 are combined together through a bonding process. At this time, the polarization direction of the GaN buffer layer 102 and the GaN channel layer 103 is upward, while the polarization direction of the GaN barrier layer 104 becomes Downward, at the interface of the GaN channel layer 103 and the GaN barrier layer 104 , due to the imbalance of po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com