A quantum dot superluminescent light-emitting diode and its manufacturing method

A technology of superluminescence and fabrication method, applied in the field of quantum dot superluminescence light-emitting diodes and their fabrication, to achieve the effects of widening gain spectrum, reducing feedback, and optimizing output spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

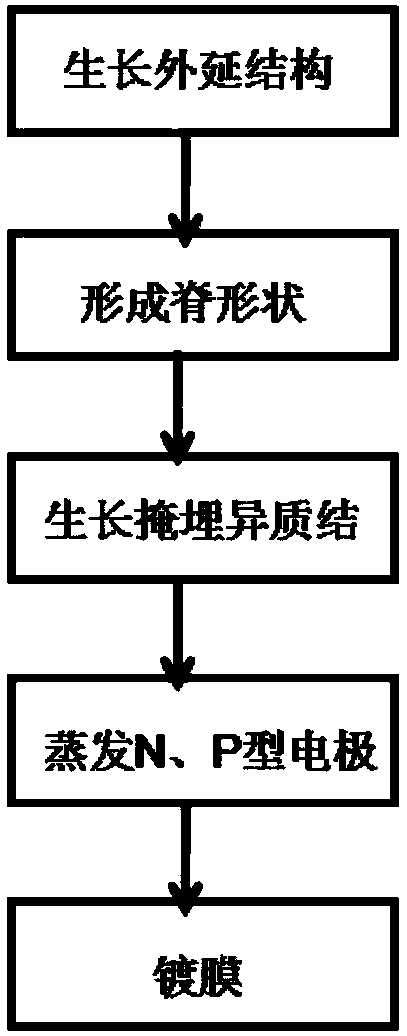

[0033] A kind of fabrication method of quantum dot superluminescent light-emitting diode that the present invention proposes, such as figure 1 As shown, the method includes the following steps:

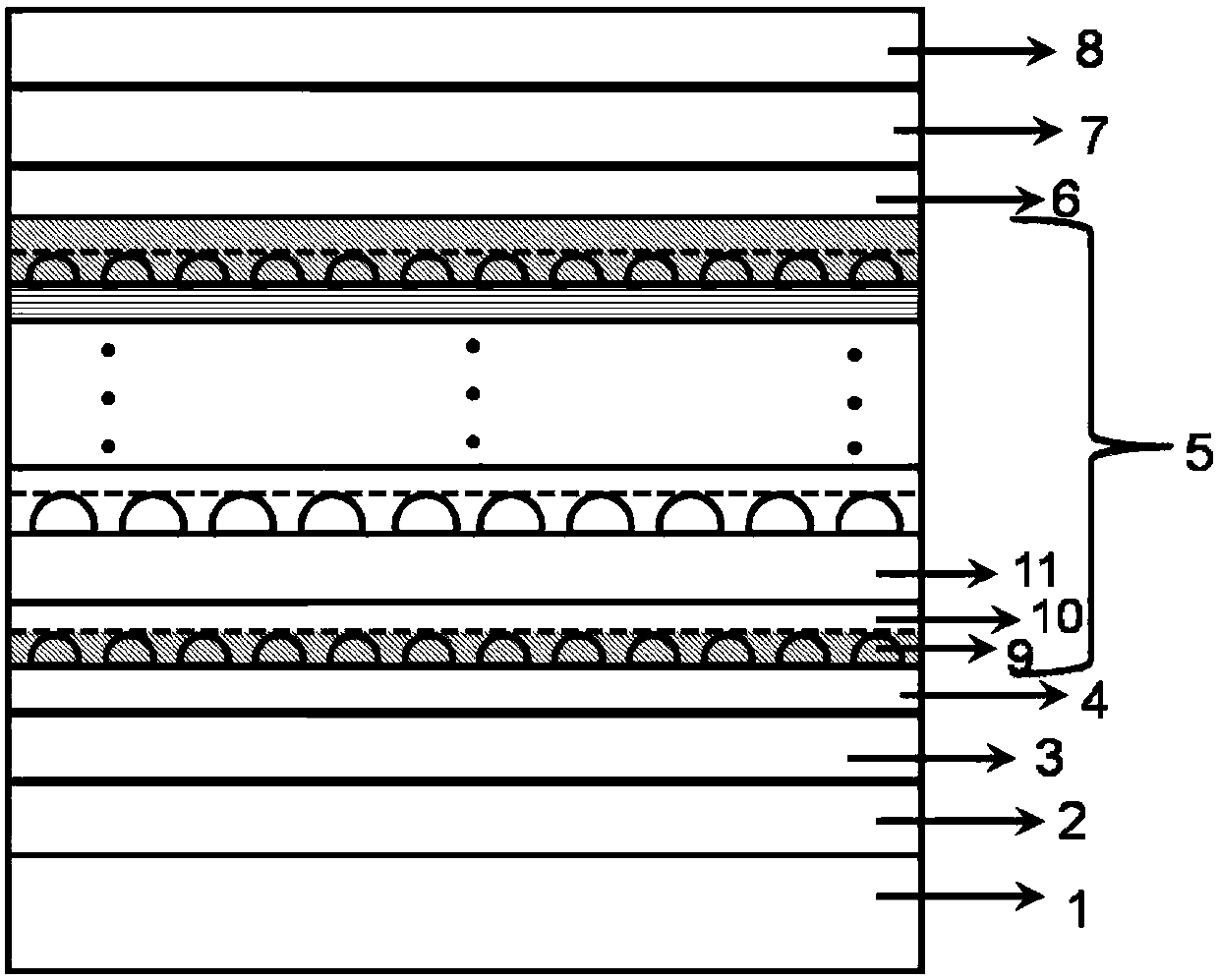

[0034] 1. One epitaxial growth step: such as figure 2 As shown, the epitaxial structure is grown once by MBE, and its structure is sequential along the crystal direction (such as figure 2 shown bottom to top) including N + -GaAs substrate layer 1, N-GaAs buffer layer 2, N-AlGaAs cladding layer 3, AlGaAs lower confinement layer 4, active region 5 containing four layers of InAs quantum dots, AlGaAs upper confinement layer 6, P-AlGaAs cladding layer 7 , P-GaAs protective layer 8 .

[0035] The active region 5 includes a first undoped GaAs layer, four layers of InAs quantum dots and a second undoped GaAs layer, each layer of InAs quantum dots includes InAs quantum dots 9 , an InGaAs capping layer 10 and a GaAs capping layer 11 .

[0036] During the growth of the active region, the l...

Embodiment 2

[0042] This embodiment is a preferred embodiment based on Embodiment 1. The fabrication method of the quantum dot superluminescent light-emitting diode proposed by the present invention is as follows: figure 1 As shown, the method includes:

[0043] 1. One epitaxial growth step: such as figure 2 shown, at N + -GaAs substrate 1, MBE growth doping concentration 1×10 at 500°C 18 200nm N-GaAs buffer layer 2, doping concentration 1×10 18 100nm N-AlGaAs cladding layer 3, 200nm AlGaAs lower confinement layer 4, active region 5 containing four layers of InAs quantum dots, then 200nm AlGaAs upper confinement layer 6 grown at 500°C, doping concentration 1×10 18 100nm P-AlGaAs cladding layer 7, doping concentration 1×10 18 The 10nm P-GaAs protective layer 8 completes an epitaxial growth, and its structure is as follows figure 2 shown.

[0044] The growth method of the active region 5 is as follows: grow a 100nm undoped GaAs layer at 500°C, grow 2ML (ML: atomic layer) InAs qu...

Embodiment 3

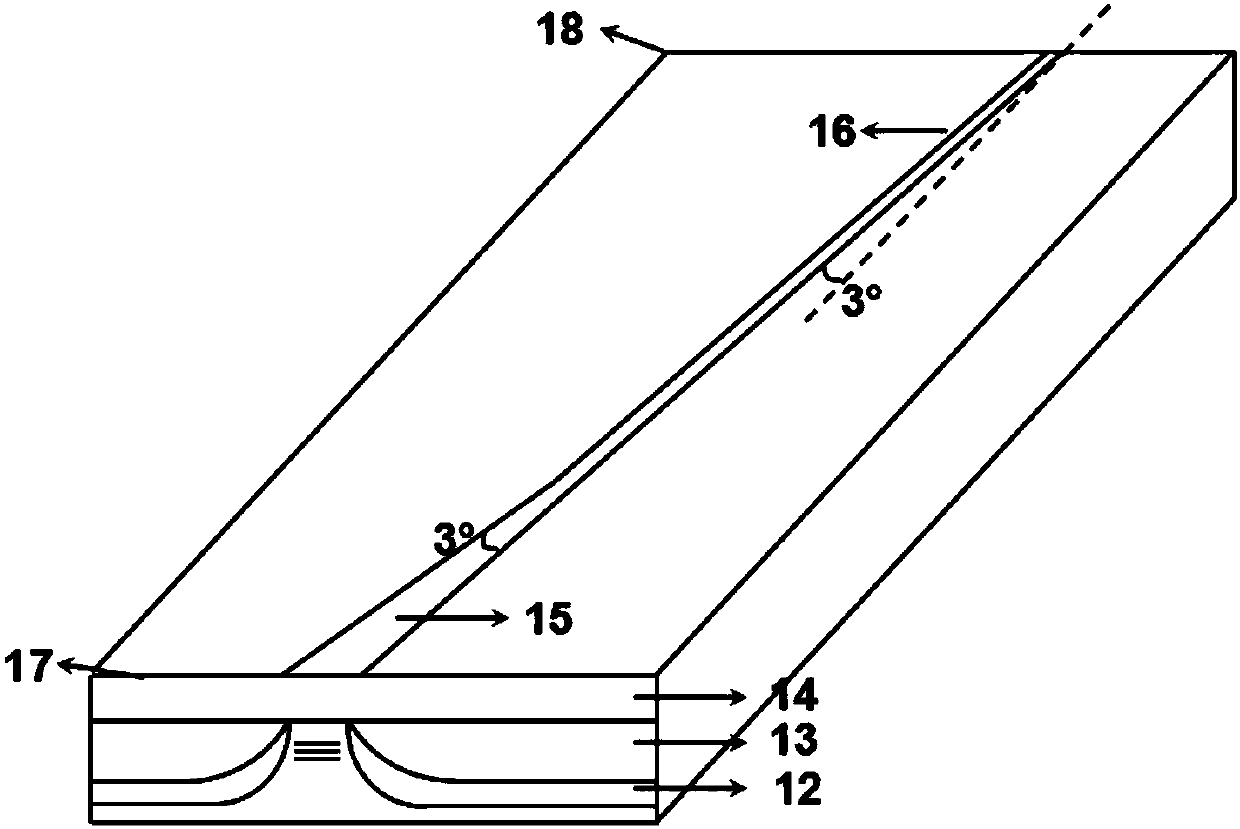

[0050] The quantum dot superluminescent light-emitting diode proposed by the present invention is as figure 2 and image 3 As shown, the quantum dot superluminescent light-emitting diode includes: a primary epitaxial structure and a buried heterojunction structure, wherein the primary epitaxial structure includes: N + -GaAs substrate layer 1, N-GaAs buffer layer 2, N-AlGaAs cladding layer 3, AlGaAs lower confinement layer 4, active region 5 containing four layers of InAs quantum dots, AlGaAs upper confinement layer 6 and P-AlGaAs cladding layer 7 ; Wherein the active region 5 includes a first undoped GaAs layer, four layers of InAs quantum dots and a second undoped GaAs layer arranged in sequence along the crystal direction.

[0051] The N-AlGaAs cladding layer 3, the AlGaAs lower confinement layer 4, the active region 5 containing four layers of InAs quantum dots, the AlGaAs upper confinement layer 6 and the P-AlGaAs cladding layer 7 form a ridge structure along the crystal d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com