Podiform silicon @ amorphous carbon @ graphene nanoscroll composite material for lithium ion battery negative material

A lithium-ion battery and composite material technology, applied in the field of pod-shaped silicon@amorphous carbon@graphene nano-roll composite materials, can solve the problems of easy cracking of the carbon protective layer, avoid pulverization, maintain integrity, and improve storage capacity. Effect of Lithium Capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

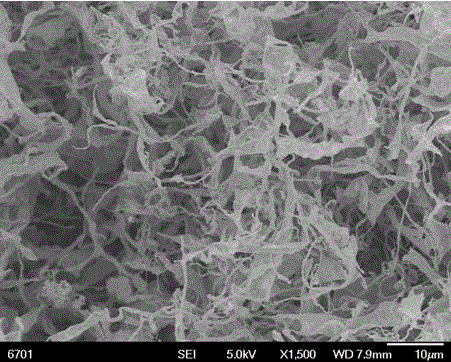

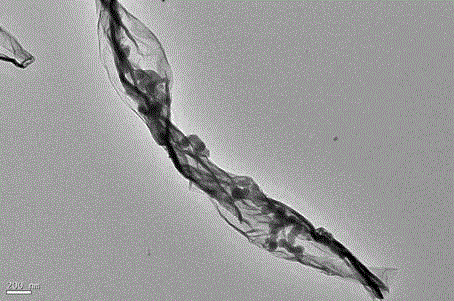

[0030] Take 500mg of commercial silicon nanopowder and stir and disperse it in absolute ethanol at a stirring rate of 200-1000rpm to form a uniform suspension. Then add 25mL Tris-HCl (10mM, pH=8.5) buffer solution and 50mg dopamine, After stirring and reacting at room temperature for 24 hours, the remaining unreacted dopamine was removed by filtration. The filtered product was washed repeatedly with distilled water and ethanol and dried in a vacuum oven for 24 hours. The dopamine-modified silicon nanopowder was named silicon@dopamine. Take 100mL graphene suspension (0.05mg / mL), add 73.5μL hydrazine hydrate to 60 o Reduce graphene under C conditions for 30 minutes, then add 5mg of silicon@dopamine prepared in the above steps, stir and heat for 10 minutes, transfer the above mixed suspension to a tubular plastic container, freeze, and place in a freeze dryer to vacuum freeze Lyophilization; the lyophilized silicon@dopamine@graphene nano-volume cylindrical body is annealed in a red...

Embodiment 2

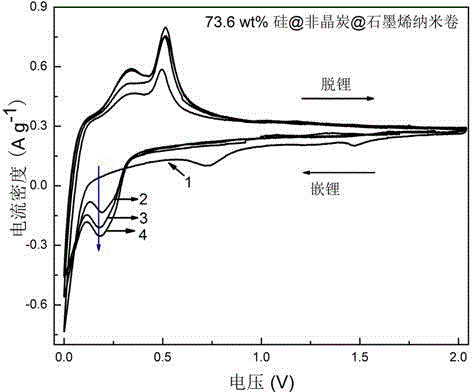

[0033] Take 100mL graphene suspension (0.05mg / mL), add 73.5μL hydrazine hydrate to 60 o Reduce graphene under C condition for 30 minutes, then add 10mg of silicon@dopamine powder prepared in Example 1, stir and heat for 10 minutes, transfer the above mixed suspension to a tubular plastic container, freeze and place it in lyophilization Freeze and freeze-dry in a vacuum machine; the freeze-dried silicon@dopamine@graphene nano-volume cylindrical body is annealed in a reducing atmosphere at a temperature of 700 o C, the annealing time is 2 hours, and the composite material is taken out after natural cooling, which is the silicon@amorphous carbon@graphene nanovolume composite material. The thermogravimetric analysis results show that the actual mass fraction of silicon in the composite material is 73.6%.

[0034] According to the electrode preparation method in Example 1, the prepared silicon@amorphous carbon@graphene nanovolume composite material, acetylene black conductive agent, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com