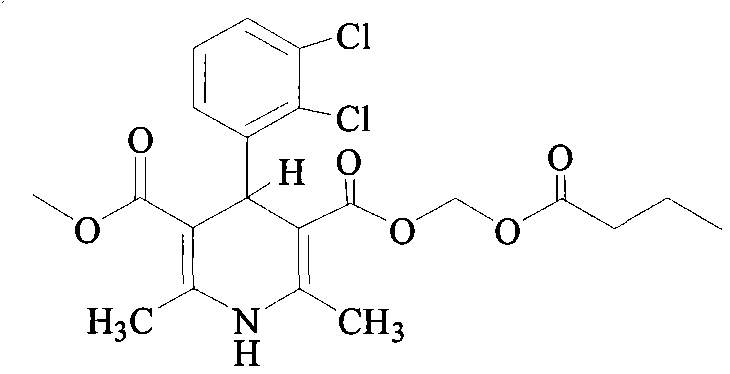

Preparation method of clevidipine butyrate injection fat emulsion

A technology of clevidipine butyrate and fat for injection, which is applied in the field of preparation of fat emulsion for clevidipine butyrate injection, can solve problems such as few detailed reports, and achieves stable quality, stable preparation process and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

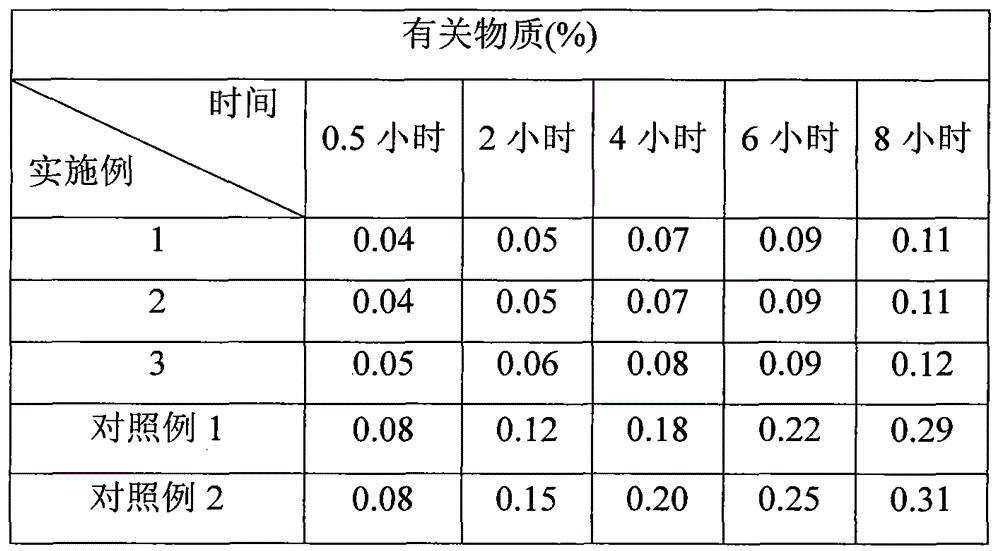

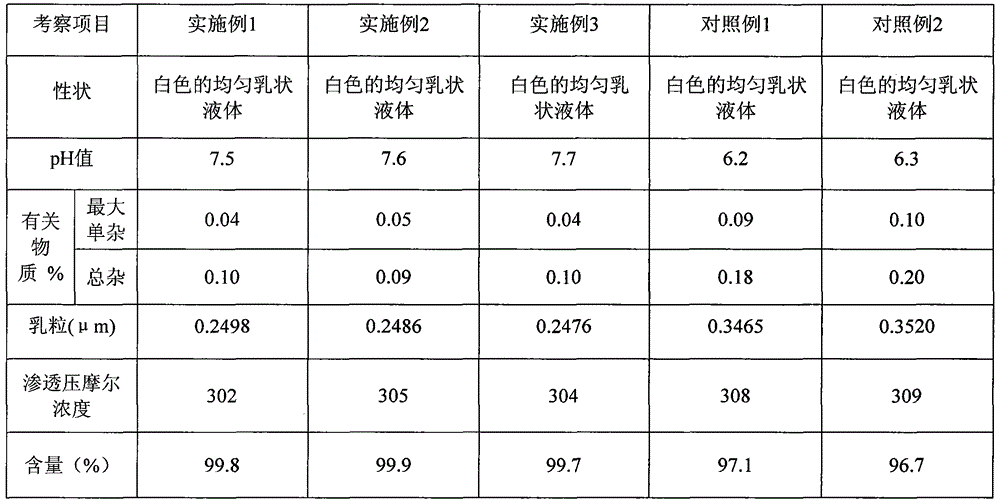

Examples

Embodiment 1

[0024] Single-dose prescription composition

[0025] Element

Dosage (mg)

Clevidipine Butyrate

25

10000

600

15

glycerin

1125

2.5

5

Water for Injection

up to 50ml

[0026] Preparation:

[0027] Dosing process:

[0028] Oil phase preparation: under the protection of nitrogen, add the prescribed amount of soybean oil, egg yolk lecithin and oleic acid into the liquid mixing tank A, stir and heat to 60°C, keep warm, add the prescribed amount of clevidipine butyrate, and high-speed (2500r / min) and stir until the clevidipine butyrate is completely dissolved.

[0029] Water phase preparation: Add the prescribed amount of glycerin, edetate disodium and water for injection into the liquid mixing tank B, stir to completely dissolve and mix evenly, control the liquid mixing temperature at 60°C, and keep warm.

[...

Embodiment 2

[0037] Single-dose prescription composition

[0038] Element

Dosage (mg)

Clevidipine Butyrate

25

10000

egg yolk lecithin

600

15

glycerin

1125

2.5

5

Water for Injection

up to 50ml

[0039] Preparation:

[0040] Dosing process:

[0041] Oil phase preparation: under the protection of nitrogen, add the prescribed amount of soybean oil, egg yolk lecithin and oleic acid into the liquid mixing tank A, stir and heat to 60°C, keep warm, add the prescribed amount of clevidipine butyrate, and high-speed (2500r / min) and stir until the clevidipine butyrate is completely dissolved.

[0042] Water phase preparation: Add the prescribed amount of glycerin, edetate disodium and water for injection into the liquid mixing tank B, stir to completely dissolve and mix evenly, control the liquid mixing temperature at 60°C, and keep warm.

[...

Embodiment 3

[0050] Single-dose prescription composition

[0051] Element

Dosage (mg)

Clevidipine Butyrate

25

10000

egg yolk lecithin

600

15

glycerin

1125

2.5

5

Water for Injection

up to 50ml

[0052] Preparation:

[0053] Dosing process:

[0054] Oil phase preparation: under the protection of nitrogen, add the prescribed amount of soybean oil, egg yolk lecithin and oleic acid into the liquid mixing tank A, stir and heat to 60°C, keep warm, add the prescribed amount of clevidipine butyrate, and high-speed (2500r / min) and stir until the clevidipine butyrate is completely dissolved.

[0055] Water phase preparation: Add the prescribed amount of glycerin, edetate disodium and water for injection into the liquid mixing tank B, stir to completely dissolve and mix evenly, control the liquid mixing temperature at 60°C, and keep warm.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com