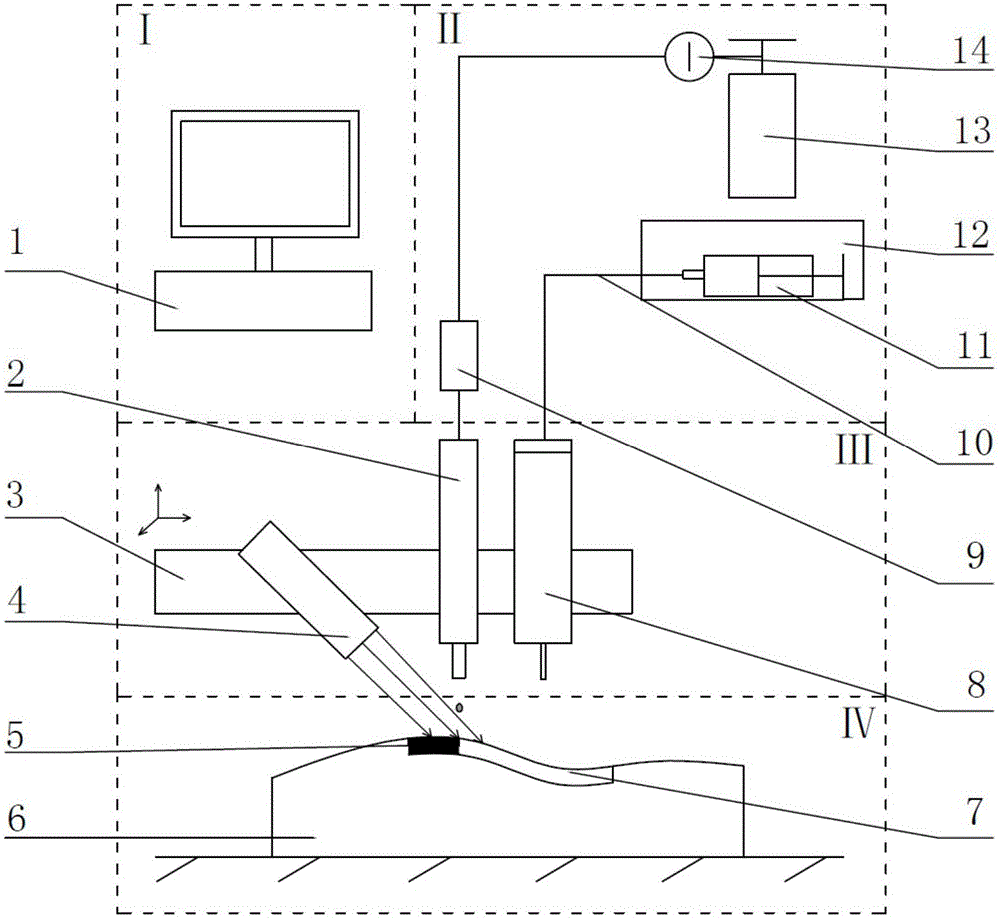

Photo-thermal composite curing 3D printing device and hook face in-situ printing method thereof

A 3D printing and light-curing technology, which is applied in medical science, prosthesis, additive processing, etc., can solve the problems of process pain, low material utilization rate, and no customized skin size and shape, so as to achieve less manual operation and increase Controllable, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

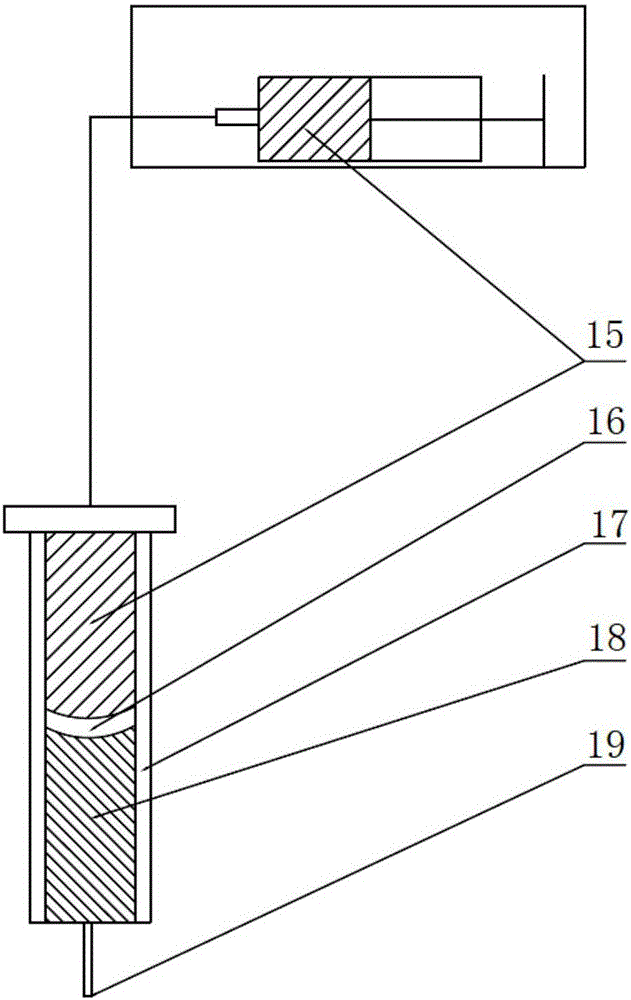

Method used

Image

Examples

Embodiment example 1

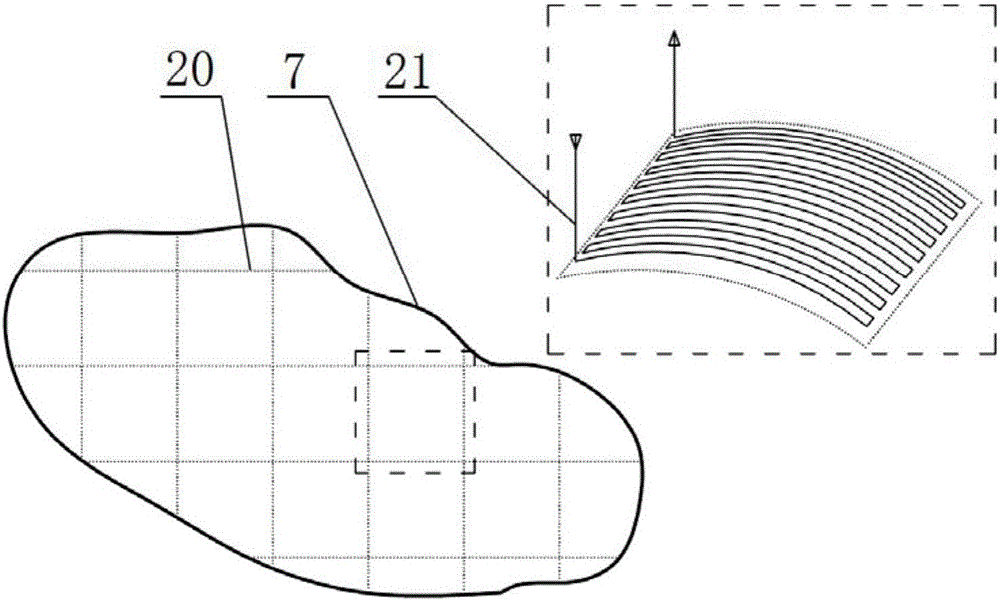

[0054] Skin-like structure printing: use two nozzle systems. The material of photocuring process nozzle system is photocurable PEDGA solution, configuration method: dissolve PEDGA and photoinitiator in deionized water so that their concentrations are 5% (w / v)-25% (w / v) and 0.5% respectively (w / v)-2% (w / v). Control parameters: The frequency of the solenoid valve controller is 2Hz-10Hz, the step distance is 0.5-1mm, the movement speed is 2-10mm / s, and the air pressure of the pressure reducing valve is 0.01-0.1MPa. ; The printing material of the temperature curing process nozzle system is gelatin, and the concentration is 5% (w / v)-40% (w / v). Control parameters: heating layer temperature 24-28°C, syringe pump flow rate 0.5-2ml / min, step distance 0.2-0.5mm, movement speed 2-10mm / s. Photocurable hydrogels with a thickness of 0.1-1mm and gelatin materials with a thickness of 0.1-1mm can be printed on curved surfaces with uniform thickness.

Embodiment example 2

[0056] Cartilage-like structure printing: use photo-curing process nozzle system, printing material is photo-curing PEDGA solution, configuration method: dissolve PEDGA and photoinitiator in deionized water so that their concentrations are 25% (w / v)-50% ( w / v), 0.5% (w / v)-2% (w / v). Control parameters: The frequency of the solenoid valve controller is 2Hz-10Hz, the step distance is 0.5-1mm, the movement speed is 2-10mm / s, and the air pressure of the pressure reducing valve is 0.05-0.1MPa. The printed cartilage-like structure has undergone mechanical performance tests, and the deformation can reach 50%, which meets the mechanical performance requirements of cartilage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com