Method for preparing CsPbBrxI3-x nanorod

A technology of nanorods and oleic acid, applied in the nano field, can solve the problems of low yield, long reaction time, complicated steps, etc., and achieve the effects of uniform structure, simplified reaction steps, and lower reaction temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

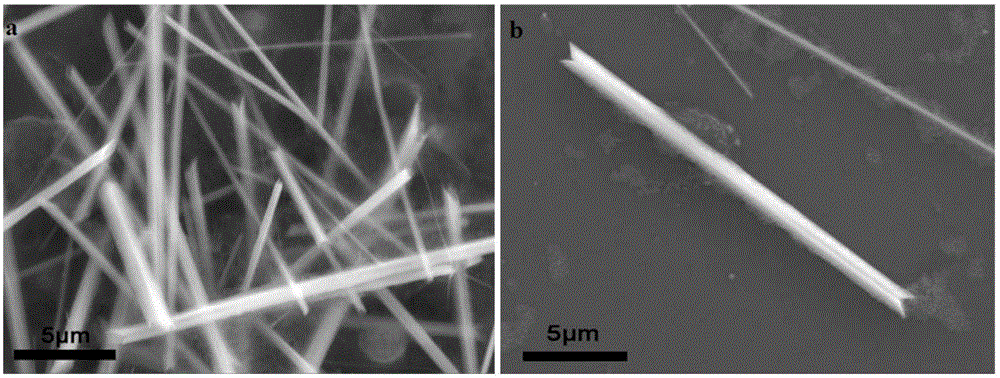

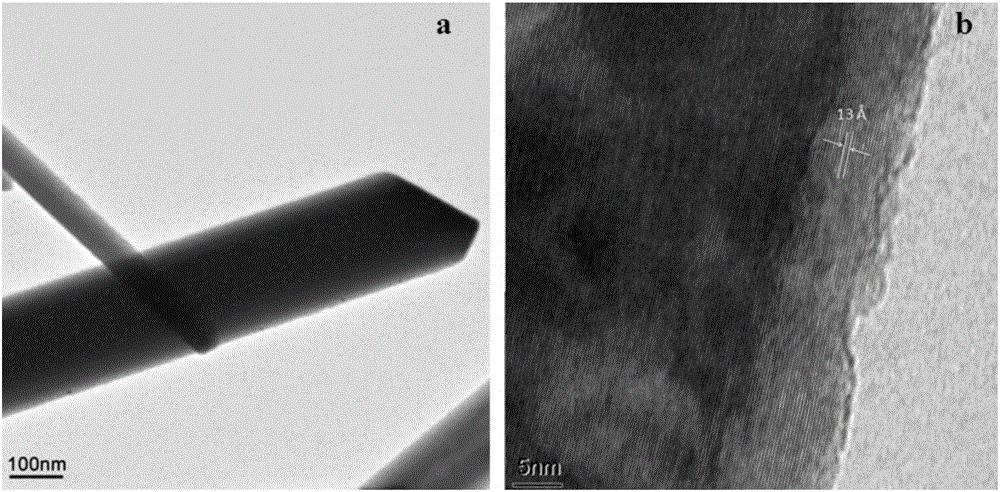

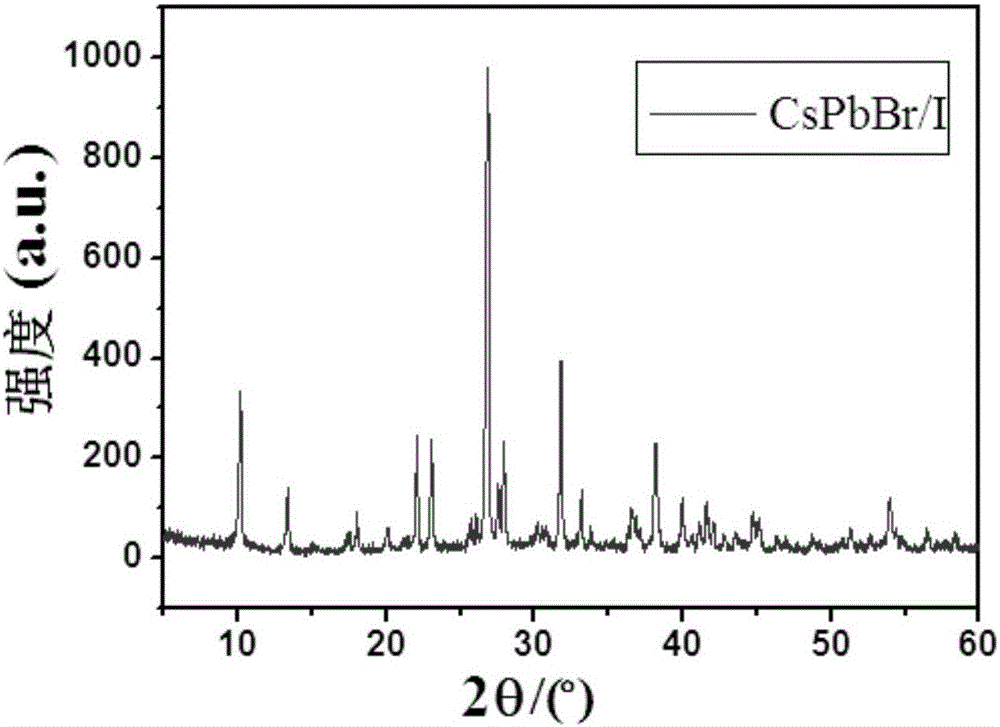

[0023] CsPbBr of the present invention x I 3-x The specific steps of the preparation method of nanorods are as follows:

[0024] (1) Cs with a concentration of 21.05 mg / ml was prepared with octadecene 2 CO 3 -ODE mixture, then add excess oleic acid to the mixture, and heat to Cs at 120°C under nitrogen atmosphere 2 CO 3 Complete reaction with OA to obtain cesium oleate solution;

[0025] (2) Take PbI according to the molar ratio of cesium and lead as 1:1.8 2 and PbBr 2 (the molar ratio of iodine and bromine is 2:1), mix the two into octadecene to prepare a mixture with a lead concentration of 36mol / L, then heat the mixture to 120°C under a nitrogen atmosphere, and then add a small amount of The ratio of oleylamine and oleic acid is 3:4 and the temperature is raised to 135°C. After heating for half an hour, PbI 2 and PbBr 2 Dissolve, then add the cesium oleate solution obtained in step (1), continue the reaction for 10-80min, put the product in an ice bath, centrifuge,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com