Regulation method for pore structure of laminated porous alumina ceramics

A technology of porous alumina and pore structure, which is applied in the field of porous ceramic materials, can solve the problems of difficult precise control of ice crystal morphology and the inability to effectively and accurately control pore structure, and achieve the effect of meeting application requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Pour the nanoscale alumina powder into deionized water and stir evenly to obtain an alumina suspension with an alumina content of 15 wt% (mass percentage);

[0026] 2) Into the alumina suspension prepared in step (1), add titanium dioxide nanopowders accounting for 1wt.% of the alumina mass, stir and disperse by ultrasonic waves to obtain a uniform alumina suspension mixed with sintering aids. turbid liquid;

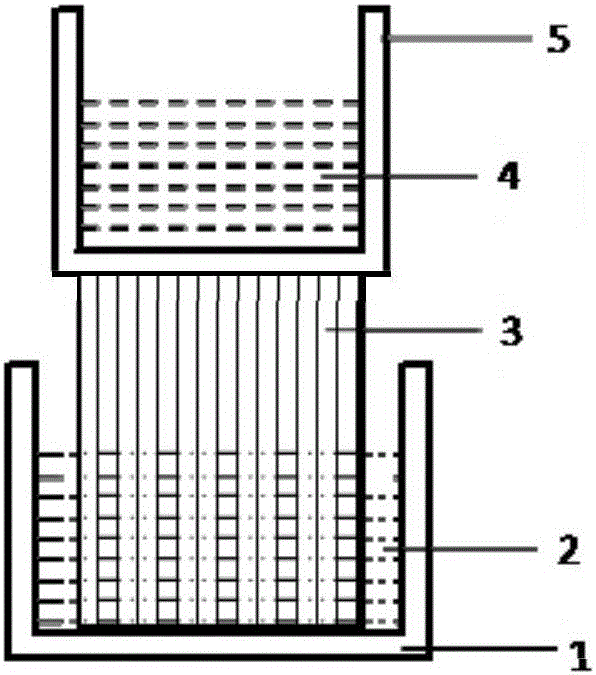

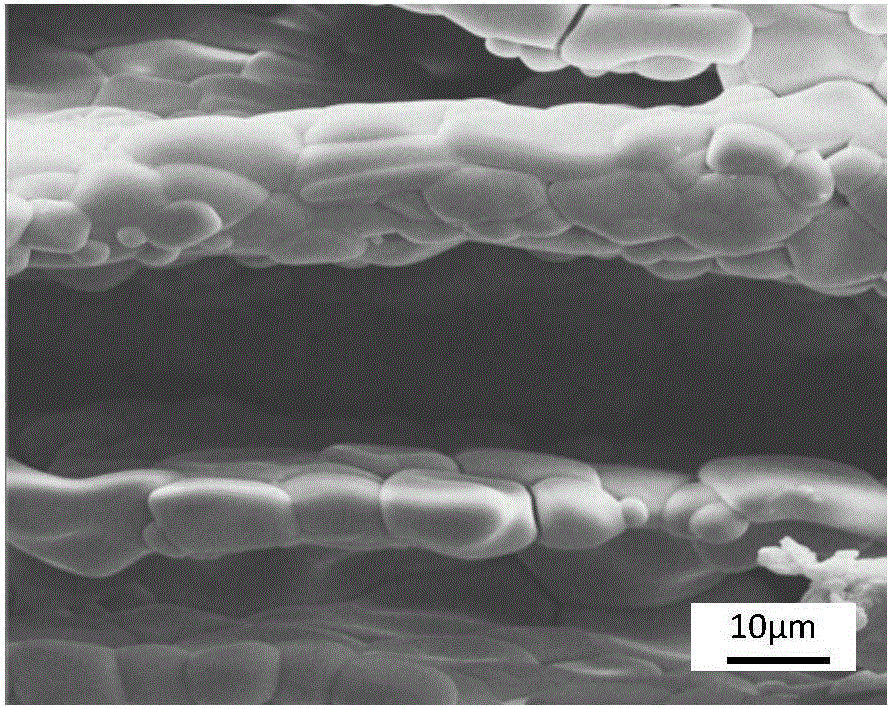

[0027] 3) the aluminum oxide suspension mixed with sintering aid obtained in step (2) is placed in a polytetrafluoroethylene container, and the wall thickness of the container is 5 mm, and then the polytetrafluoroethylene container is placed on a solid On the metal block (as a cold finger), the lower half of the metal block is immersed in the refrigerant, and the aluminum oxide suspension mixed with the sintering aid is directional frozen through the heat transfer of the metal block until the suspension is completely solidified. Until the ice is reached, the i...

Embodiment 2

[0032] 1) Pour the nanoscale alumina powder into deionized water and stir evenly to obtain an alumina suspension with an alumina content of 15 wt% (mass percentage);

[0033] 2) In the alumina suspension prepared in step (1), 3 wt.% titanium dioxide nanopowder is mixed into the alumina suspension, stirred and dispersed by ultrasonic waves to obtain a uniform alumina suspension mixed with sintering aids. turbid liquid;

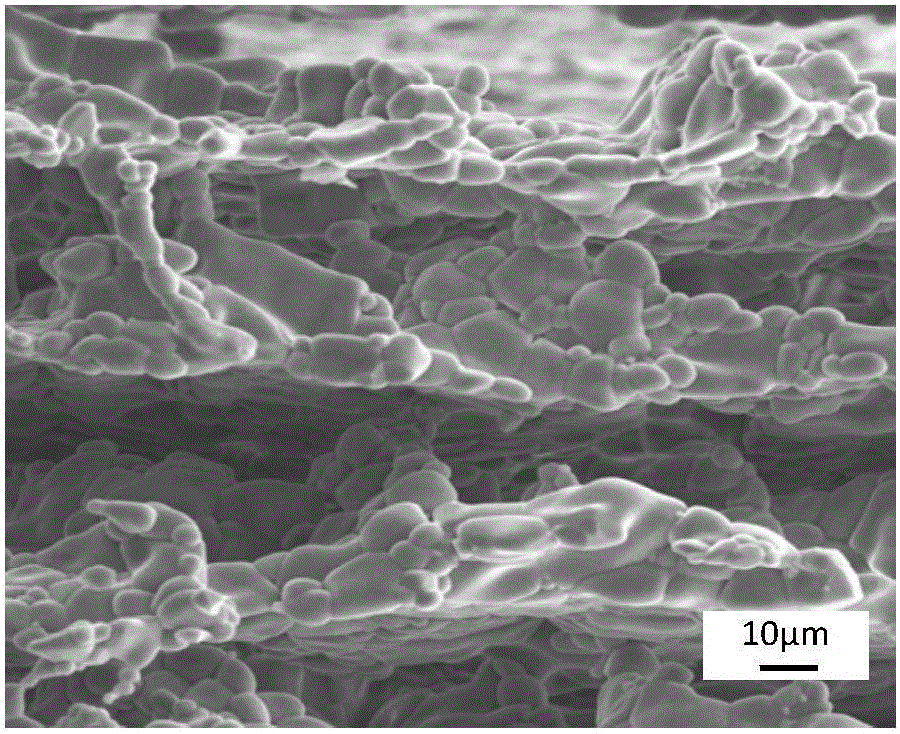

[0034] 3) the aluminum oxide suspension mixed with sintering aid obtained in step (2) is placed in a polytetrafluoroethylene container, and the wall thickness of the container is 5 mm, and then the polytetrafluoroethylene container is placed on a solid On the metal block (as a cold finger), the lower half of the metal block is immersed in the refrigerant, and the aluminum oxide suspension mixed with the sintering aid is directional frozen through the heat transfer of the metal block until the suspension is completely solidified. Until the ice is reached, the i...

Embodiment 3

[0039] 1) Pour the nanoscale alumina powder into deionized water and stir evenly to obtain an alumina suspension with an alumina content of 15 wt% (mass percentage);

[0040] 2) In the alumina suspension prepared in step (1), add silica nano-powders accounting for 1wt.% of the mass of alumina, stir and disperse by ultrasonic waves to obtain a uniform sintering aid mixed with the alumina suspension. Aluminum suspension;

[0041] 3) the aluminum oxide suspension mixed with sintering aid obtained in step (2) is placed in a polytetrafluoroethylene container, and the wall thickness of the container is 5 mm, and then the polytetrafluoroethylene container is placed on a solid On the metal block (as a cold finger), the lower half of the metal block is immersed in the refrigerant, and the aluminum oxide suspension mixed with the sintering aid is directional frozen through the heat transfer of the metal block until the suspension is completely solidified. Until the ice is reached, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com