Composting treatment system with automatic deodorization capacity

A treatment system and composting technology, applied in the field of environmental protection and comprehensive utilization of resources, can solve the problems of bacteria growth, reduced air permeability, easy penetration of odorous gas molecules, even bacteria and aerosols, etc., to achieve the effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

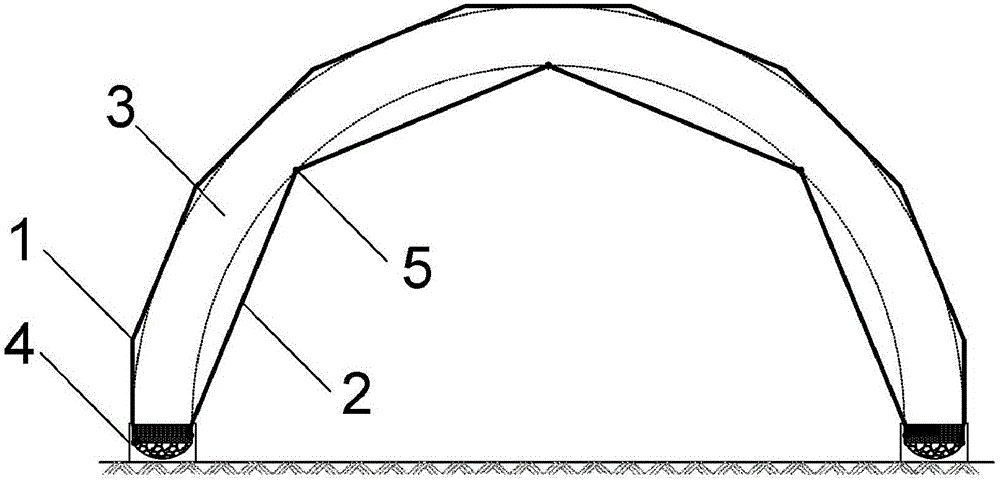

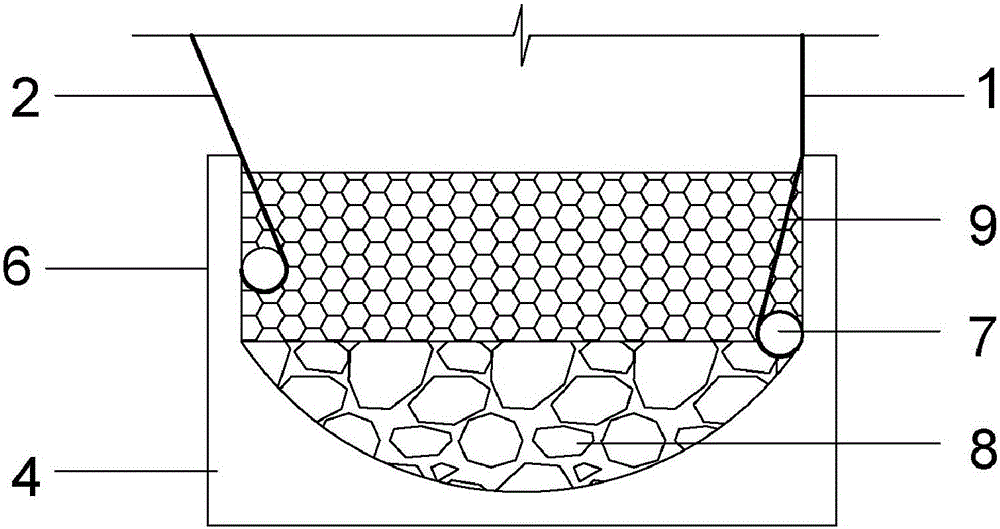

[0032] A self-deodorizing composting system, such as figure 1 As shown, it includes an outer membrane 1, an inner membrane 2, an air-rib frame 3 and a deodorizing base 4. There are two deodorizing bases 4, and the outer membrane 1 and the inner membrane 2 are stretched by the air-rib frame 3. And the two ends of the outer membrane 1 and the inner membrane 2 are respectively fixed on two deodorizing bases 4, thereby forming a closed space between the outer membrane 1 and the inner membrane 2, the outer membrane 1 is located outside the air-ribbed skeleton 3, and the outer membrane 1. Air-impermeable and water-permeable fabrics are used. The inner membrane 2 is located inside the air-ribbed skeleton 3. The inner membrane 2 is made of air-permeable and water-impermeable fabrics. The inner membrane 2 is used to place the stack 22, and the malodorous gas and water vapor generated by the stack 22 Through the inner membrane 2, it enters into the enclosed space formed between the oute...

Embodiment 2

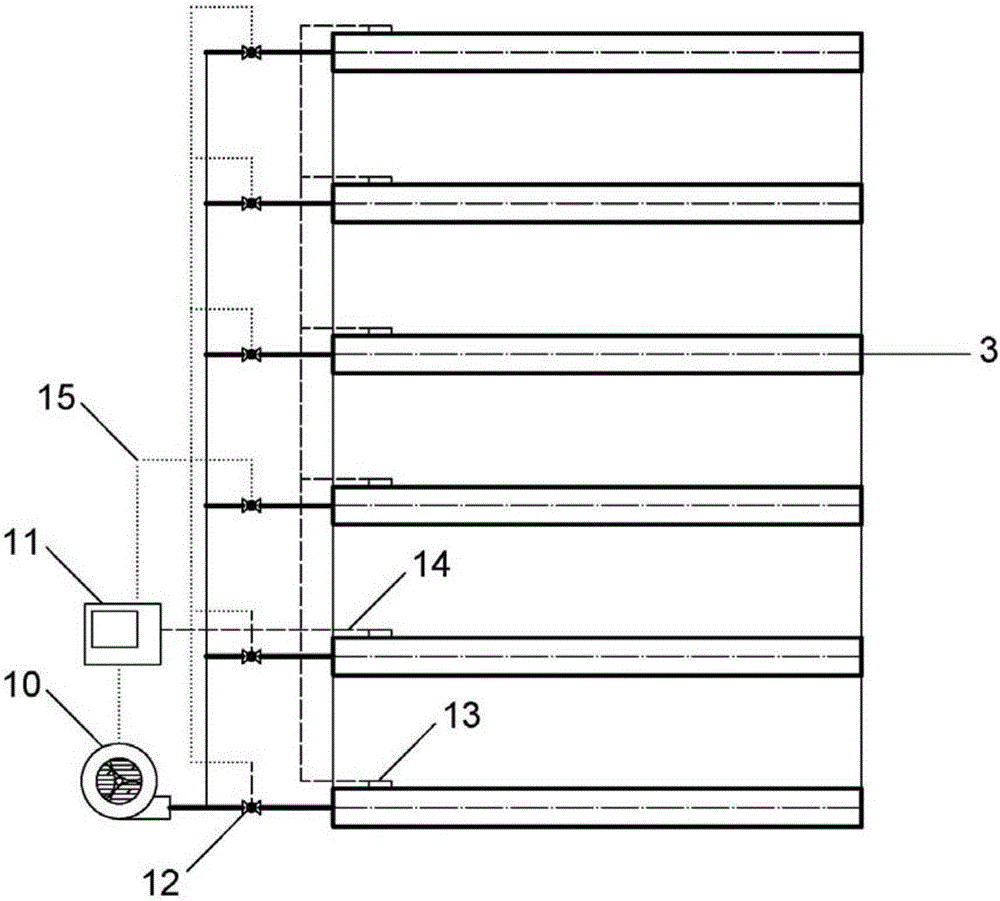

[0043] Such as Figure 5 As shown, the combined device 21 of the present invention is applied to the primary fermentation stage of the positive pressure forced ventilation composting process. The stack 22 is placed in the combination device 21 , the blower III 23 is placed outside, and the blower III 23 ventilates to the inside of the combination device 21 through the ventilation pipe 24 . The water vapor, malodorous gas and exhaust gas produced by the stack 22 will pass through the inner membrane 2, but can be completely blocked by the outer membrane 1, and the waste water and waste gas formed can pass through the base 4 and be released. be processed. Therefore, no odor is perceived outside the outer membrane 1 .

Embodiment 3

[0045] Such as Figure 5 As shown, the combination device 21 of the present invention is applied to the secondary fermentation stage of composting. Since the content of easily degradable organic matter in the biomass waste in the secondary fermentation stage is already low, the water content decreases, so the oxygen demand decreases, and the blower III 23 can be turned off. instead of directly using Figure 4 The air blower II 16 in the air supply keeps the oxygen content in the stacking space greater than 10%, and accelerates the decomposing of the stack body 22.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com