Halogen-free and environment-friendly EPDM (Ethylene-Propylene-Diene Monomer) rubber/negative oxygen ion powder mixed closed-cell secondary foaming material and preparation method thereof

A technology of EPDM rubber and negative oxygen ion powder, which is applied in the field of foaming materials, can solve the problems of poor dispersibility, failure to improve the air quality of the surrounding environment and benefit physical and mental health, and cannot reach per cubic centimeter. The effect of rate synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] A preparation method of a halogen-free environment-friendly EPDM rubber / negative oxygen ion powder blended closed-cell secondary foaming material includes the following steps:

[0066] (1) Preparation of negative oxygen ion pre-mixed powder: 100PHR tourmaline powder, 100PHR Wizard R series plastic / rubber additive 1250 mesh, 5PHR chelating titanate coupling agent, 30PHR magnesium strong powder into Φ800 *1000mm high-speed stirring tank, stirring for 12 minutes, continuously controlling the temperature at 80°C±5°C during the stirring process, the negative oxygen ion premixed powder is obtained after the stirring is completed, and the negative oxygen ion premixed powder is weighed according to the formula weight PHR ratio Repackaging

[0067] (2) Mixing: a. Premix 100PHR EPDM rubber, 35PHR negative oxygen ion premixed powder, 30PHR carbon black, 1.5PHR antifogging agent, 2PHR antioxidant, 1.5PHR antioxidant , 1.5PHR dispersant, 1PHR flow agent, 1PHR plasticizer stearic acid, 4...

Embodiment 2

[0086] The preparation method of the EPDM / PP / TPE / negative oxygen ion powder blended closed-cell secondary foaming material in Example 2 is completely the same as that of Example 1, except that the proportions of the components in Example 2 are as follows:

[0087] EPDM rubber 100PHR;

[0088] Negative oxygen ion premixed powder 45PHR;

[0089] Carbon black 25PHR;

[0090] Softener 28PHR;

[0091] Anti-fogging agent 1.5PHR;

[0092] Anti-aging agent 2PHR;

[0093] Antioxidant 1.5PHR;

[0094] Dispersant 2PHR;

[0095] Flow agent 1PHR;

[0096] Plasticizer 1.2PHR;

[0097] Curing agent 2PHR;

[0098] Accelerator 2.6PHR;

[0099] Foaming agent 4.6PHR;

[0100] Foaming aid 5PHR;

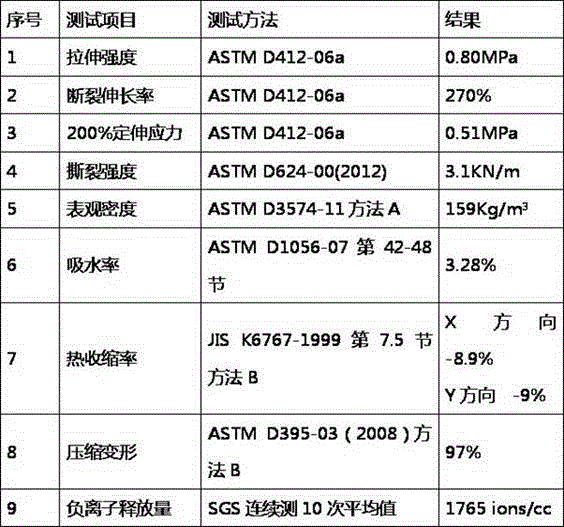

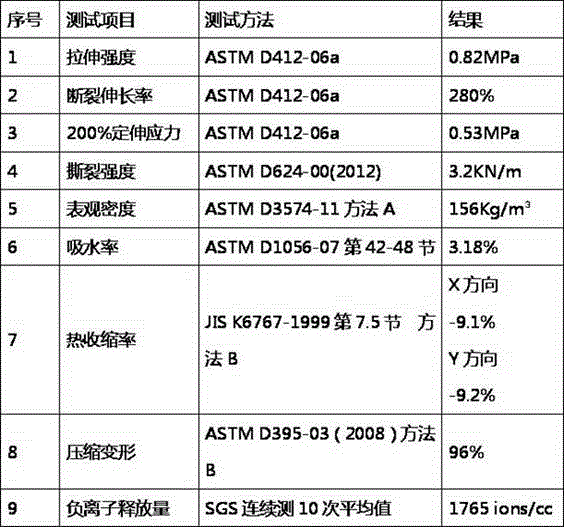

[0101] The physical properties of the halogen-free environmentally friendly EPDM rubber / negative oxygen ion powder blended closed-cell secondary foam material prepared in Example 2 are shown in Table 4 below:

[0102]

[0103] Table 4. Physical properties of Example 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com