Environment-friendly ecological wood and negative oxygen ion powder blended closed-cell secondary foamed material and preparation method thereof

A kind of negative oxygen ion powder, secondary foaming technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

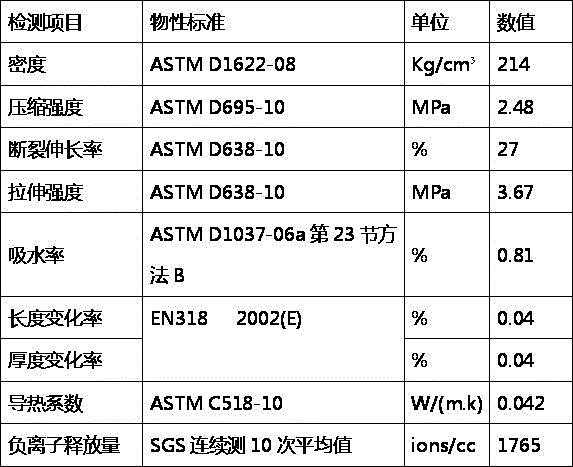

Embodiment 1

[0055] A preparation method of an environmentally friendly ecological wood / negative oxygen ion powder blended closed-cell secondary foaming material, comprising the following steps:

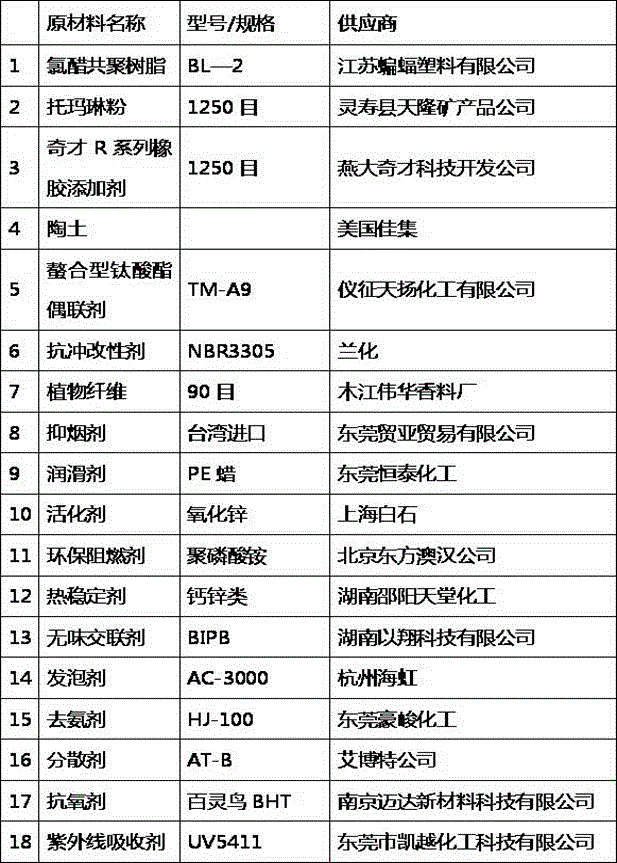

[0056] (1) Preparation of negative oxygen ion premixed powder: Blend and stir 100PHR tourmaline powder, 100PHR wizard R series plastic / rubber additive 1250 mesh, 5PHR chelating titanate coupling agent, and 100PHR clay for 12 Minutes, during the stirring process, the temperature was continuously controlled at 80°C, and the stirring was completed to obtain the negative oxygen ion premixed powder;

[0057] (2) Plant fiber pretreatment: bake the plant fiber in an oven to reduce the water content of the plant fiber to below 2.5%, weigh 20PHR of the above-mentioned treated plant fiber with a water content lower than 2.5%, and put it into a high-speed mixer , add 2PHR chelating titanate coupling agent, stir at high speed for 9 minutes and release;

[0058] (3) Internal mixer mixing: 25PHR of plant fibe...

Embodiment 2

[0071] The preparation method of the environmentally friendly ecological wood / negative oxygen ion powder blended closed-cell secondary foaming material described in embodiment 2 is completely consistent with embodiment 1, and the difference is that the weight ratio of the raw materials used in embodiment 2 is as follows:

[0072] Vinyl chloride copolymer resin 100 PHR

[0073] Negative oxygen ion premixed powder 60 PHR;

[0074] Impact Modifier 10 PHR

[0075] Vegetable fiber 25 PHR

[0076] Smoke suppressant 15 PHR

[0077] Lubricant 1.5 PHR

[0078] Activator 5 PHR

[0079] Environmental Flame Retardant 8 PHR

[0080] Heat Stabilizer 6 PHR

[0081] Odorless Crosslinker 1 PHR

[0082] Blowing agent 3.5 PHR

[0083] Ammonia Remover 2 PHR.

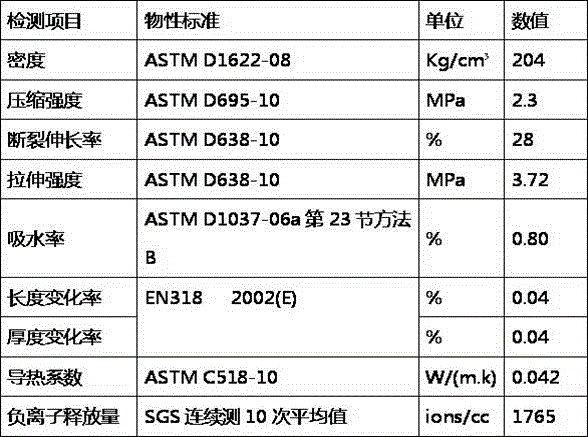

[0084] The physical properties of the environmentally friendly ecological wood / negative oxygen ion powder blended closed-cell secondary foaming material prepared by embodiment 2 are shown in Table 3 below:

[0085]

[0086] Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com