Acrylic acid and its ester flocking glue and its preparation method and flocking process

An acrylate and butyl methacrylate technology, which is applied in the field of flocking adhesives, can solve problems such as poor air permeability, unfavorable air circulation in flocking glue, failure to keep soft and plump fluff, and hard fluff to the touch. To achieve the effect of improving loose and porous characteristics, good elasticity, and improving air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

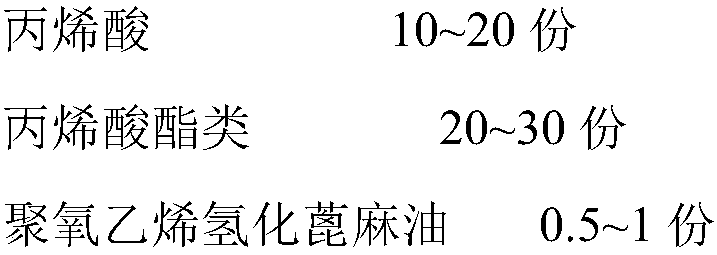

Method used

Image

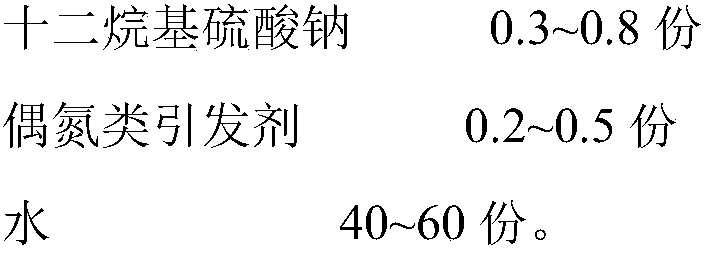

Examples

Embodiment 1

[0049] (1) Add 10 parts of acrylic acid, 10 parts of methyl acrylate, 10 parts of butyl acrylate and 40 parts of water successively in the three-necked flask to stir, the stirring speed is 100r / min, and feed nitrogen flow, the feeding speed is 20ml / min, heated up to 55°C under nitrogen atmosphere, and held for 10 min;

[0050] (2) Add 0.5 parts of polyoxyethylene hydrogenated castor oil and 0.3 parts of sodium lauryl sulfate to the reaction system at the same time, the addition speed is 0.1 parts per minute, wait until they are stirred evenly, and the temperature is raised to 65 ° C;

[0051] (3) Add 0.2 parts of azo initiator to the reaction system, heat up to 75°C under stirring, and react for 2 hours;

[0052] (4) Cool down to room temperature, add hydrogen peroxide, adjust the pH to 7 with ammonia water, and pack the material.

Embodiment 2

[0054] (1) Add 10 parts of acrylic acid, 10 parts of methyl acrylate, 10 parts of butyl acrylate and 40 parts of water successively in the three-necked flask to stir, the stirring speed is 100r / min, and feed nitrogen flow, the feeding speed is 20ml / min, the temperature was raised to 45°C under nitrogen atmosphere, and the temperature was kept for 10 min;

[0055] (2) Add 1 part of butyl methacrylate and 1 part of hydroxypropyl methacrylate to the reaction system, wait until it is evenly stirred, and raise the temperature to 55°C, and keep it warm for 10 minutes;

[0056] (3) Add 0.5 parts of polyoxyethylene hydrogenated castor oil and 0.3 parts of sodium lauryl sulfate to the reaction system at the same time, the addition speed is 0.1 parts per minute, wait for it to stir evenly, and heat up to 65 ° C;

[0057] (4) Add 1 part of silicone resin polyether emulsion, 1 part of ethylenediaminetetraacetic acid and 0.3 part of azo initiator into the reaction system, heat up to 75°C ...

Embodiment 3

[0060] (1) Add 15 parts of acrylic acid, 10 parts of methyl acrylate, 10 parts of isooctyl acrylate and 50 parts of water to the three-necked flask and stir at a stirring speed of 110 r / min, and feed nitrogen flow at a speed of 25 ml / min, heated up to 45°C under a nitrogen atmosphere, and held for 10 minutes;

[0061] (2) Add 2 parts of butyl methacrylate and 2 parts of hydroxypropyl methacrylate into the reaction system, wait until it is evenly stirred, and raise the temperature to 55°C, and keep it warm for 10 minutes;

[0062] (3) Add 0.7 parts of polyoxyethylene hydrogenated castor oil and 0.5 parts of sodium lauryl sulfate to the reaction system at the same time, the addition speed is 0.1 parts per minute, wait for it to stir evenly, and heat up to 65 ° C;

[0063] (4) Add 2 parts of silicone resin polyether emulsion, 3 parts of ethylenediaminetetraacetic acid and 0.4 part of azo initiator into the reaction system, heat up to 75°C under stirring conditions, and react for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com