Lightweight composite solid wallboard and manufacturing method thereof

A manufacturing method and solid technology, applied in manufacturing tools, chemical instruments and methods, building structures, etc., can solve the problems of easy cracks in the bonding seam between the sandwich layer and the panel, low stability of the wall panel, and short service life. Achieve the effect of high construction efficiency, ultra-light weight and strong waterproofness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. Examples are used to illustrate the present invention, but are not used to limit the protection scope of the present invention.

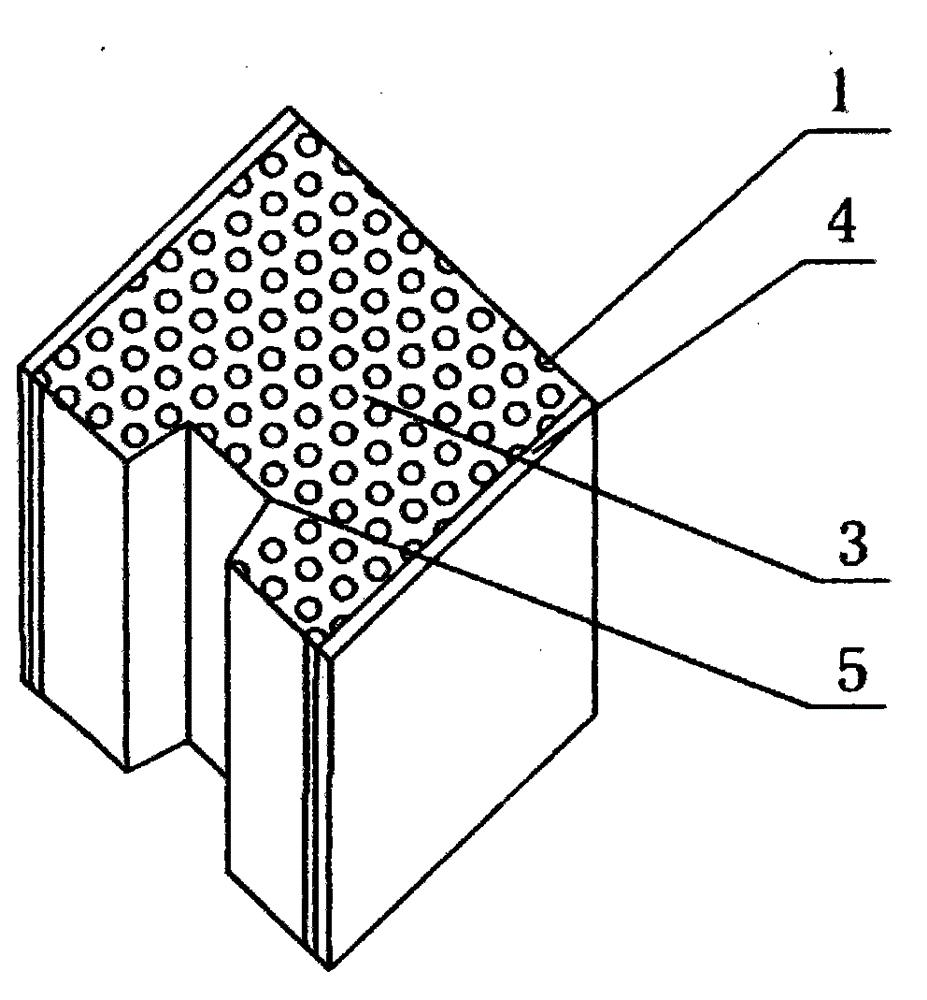

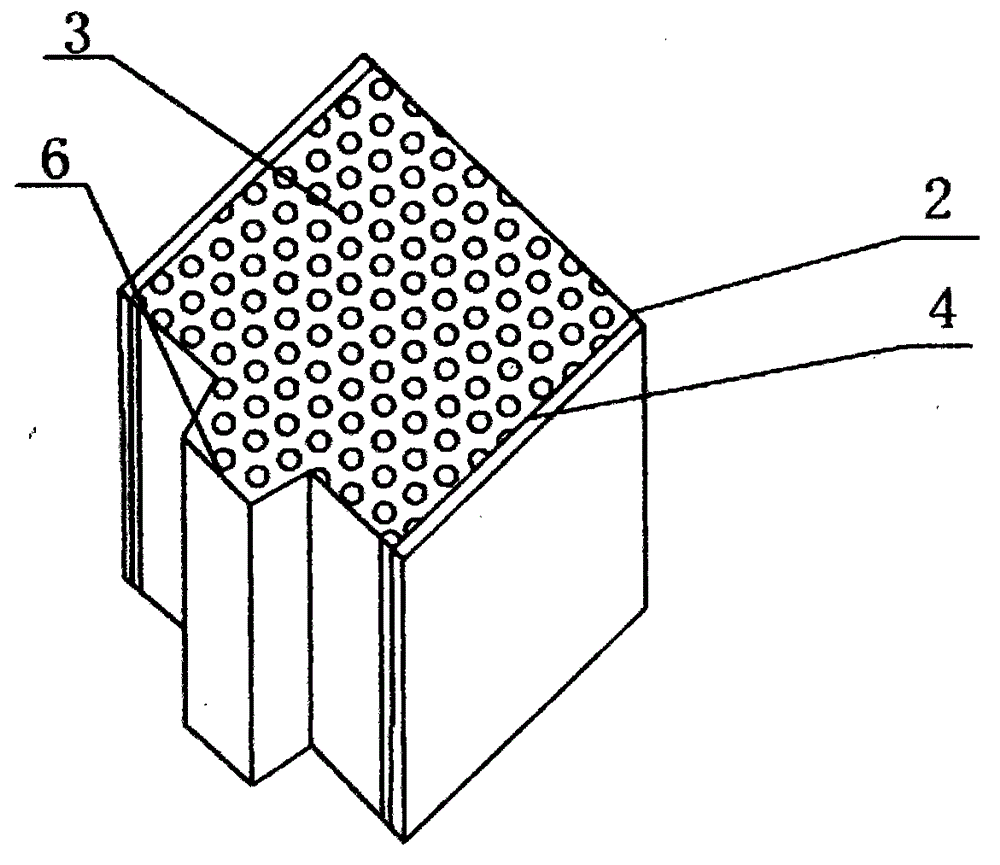

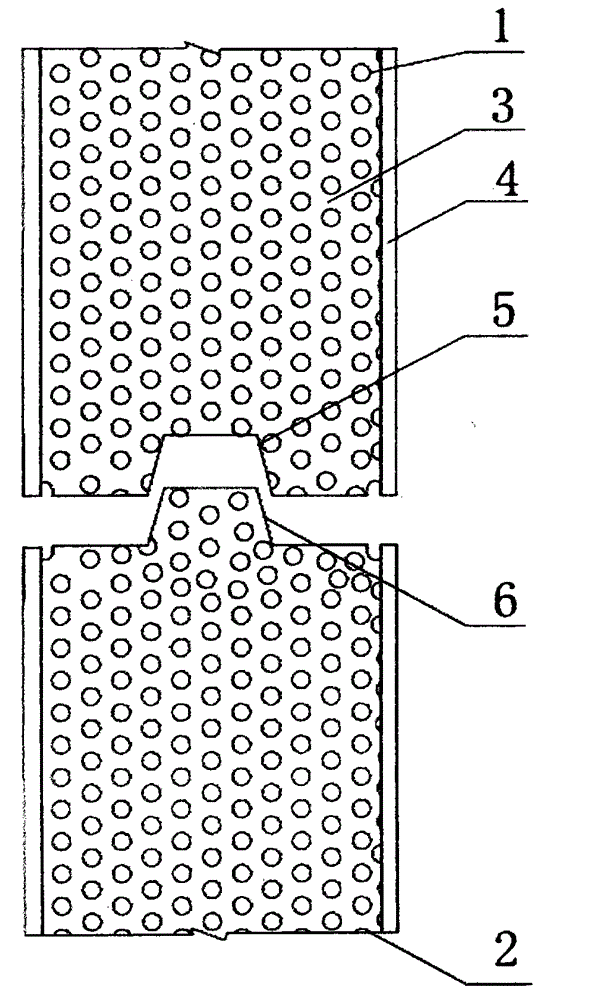

[0019] like figure 1 , figure 2 and image 3 As shown, a lightweight composite solid wall panel is composed of a first body 1 and a second body 2 whose sides are butted together; both the first body 1 and the second body 2 include a concrete sandwich layer 3 and the surface layer 4 pasted on both sides of the concrete material sandwich layer 3, the surface layer 4 is a fiber cement board, and the concrete material sandwich layer 3 is made of cement, solid particles, benzene particles and a binder composite species It is formed by mixing one or more kinds; the concrete material sandwich layer on the rear side of the first main body 1 is provided with a letter joint groove 5, and the concrete material layer on the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com