Compound purifying device for diesel engine tail gas

A technology of composite purification and diesel engine, applied in the direction of exhaust device, muffler device, mechanical equipment, etc., can solve the problems of high cost of purification device, occupying space of exhaust pipe, complicated structure of muffler, etc., achieving compact structure, easy installation and disassembly , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

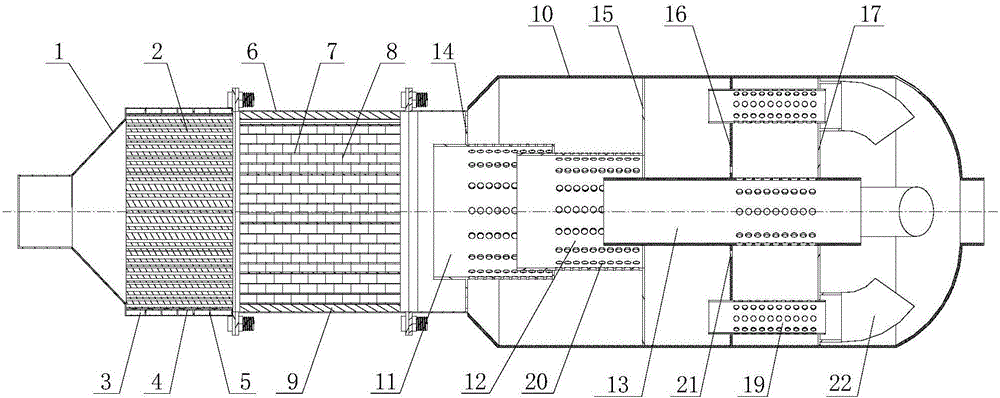

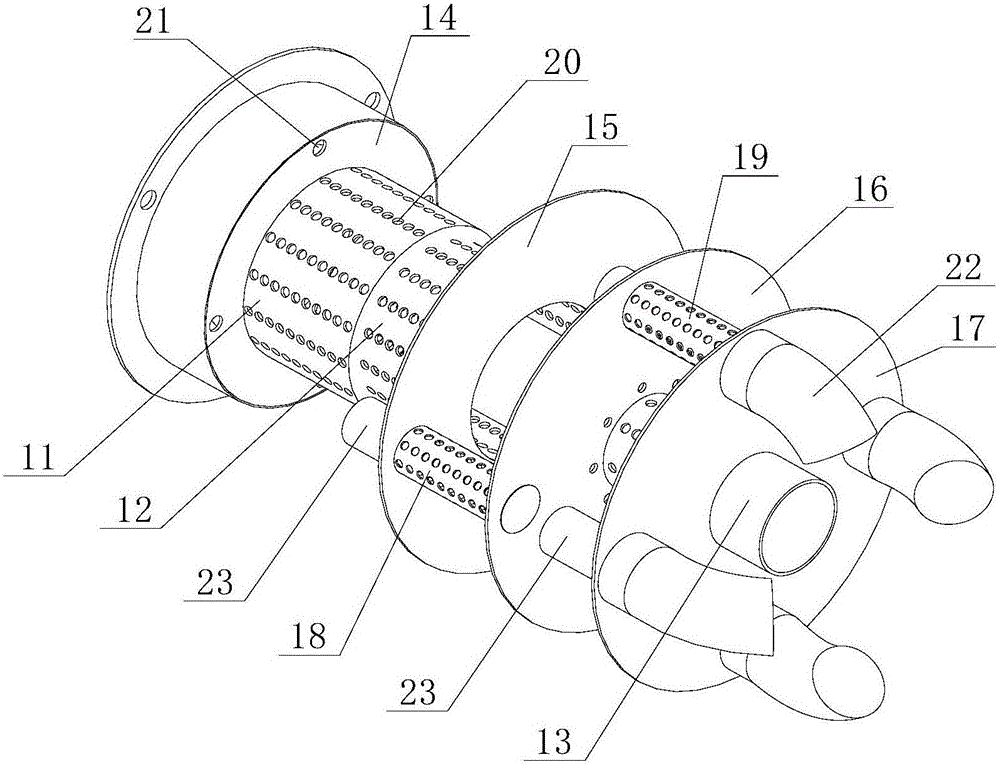

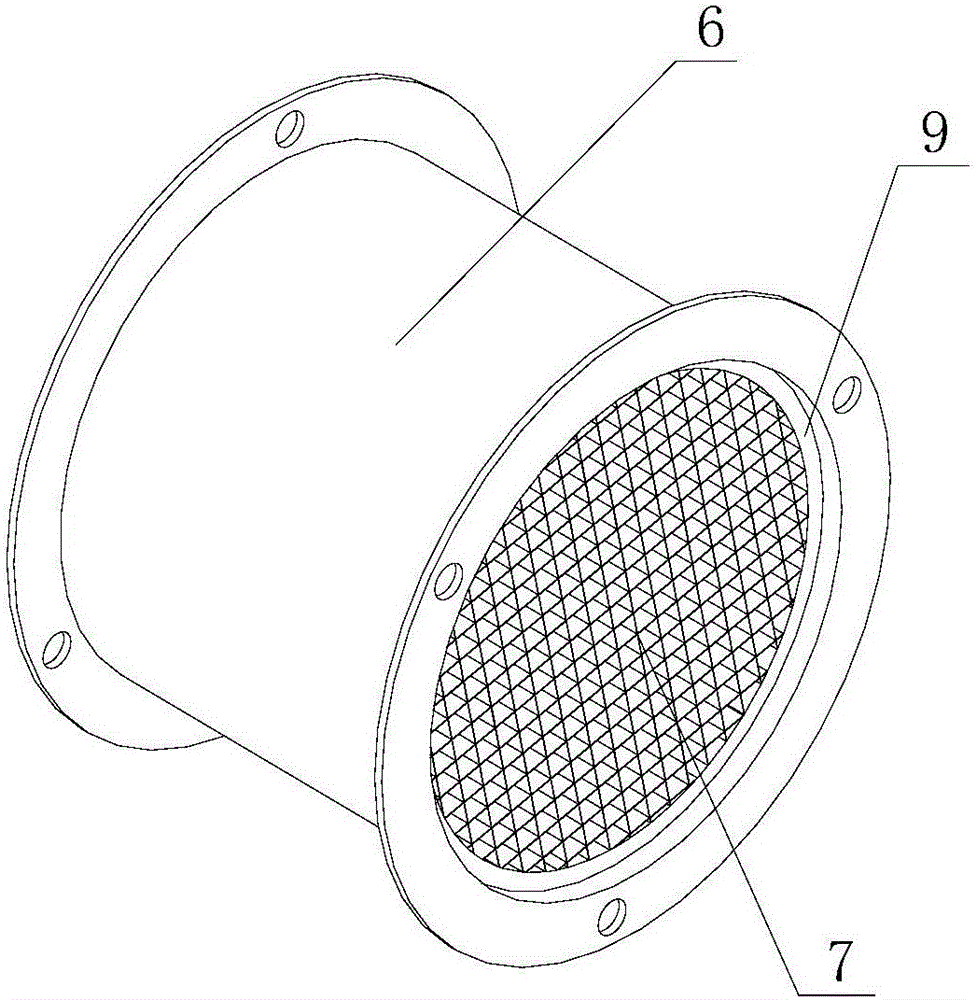

[0019] figure 1 It is a structural schematic diagram of the present invention; figure 2 A partial perspective view of the exhaust muffler; image 3 It is a schematic diagram of the structure of the particle trapping device; Figure 4 It is a partial three-dimensional view of the particle trapping device, as shown in the figure: the diesel engine exhaust recovery purification and noise reduction composite device in this embodiment includes a catalytic oxidation device, a particulate trapping device and an exhaust muffler; the catalytic oxidation device includes a device There is a first casing 1 with an air inlet and an exhaust port and a purification catalyst carrier 2 fixed in the first casing 1; a catalyst is loaded on the purification catalyst carrier 2; the first casing 1 corresponds to the side surface of the purification catalyst carrier 2 A first resonant cavity 3 is provided and the mouth of the first resonant cavity 3 faces the purification catalyst carrier 2; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com