Automobile engine

A technology of automobile engine and engine body, which is applied in the direction of machines/engines, mechanical equipment, valve driving devices, etc., can solve the problems of high engine height, high manufacturing cost, high technical requirements, etc., and achieve reduced energy consumption, low processing difficulty, and reduced The effect of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail through the embodiments below in conjunction with the accompanying drawings.

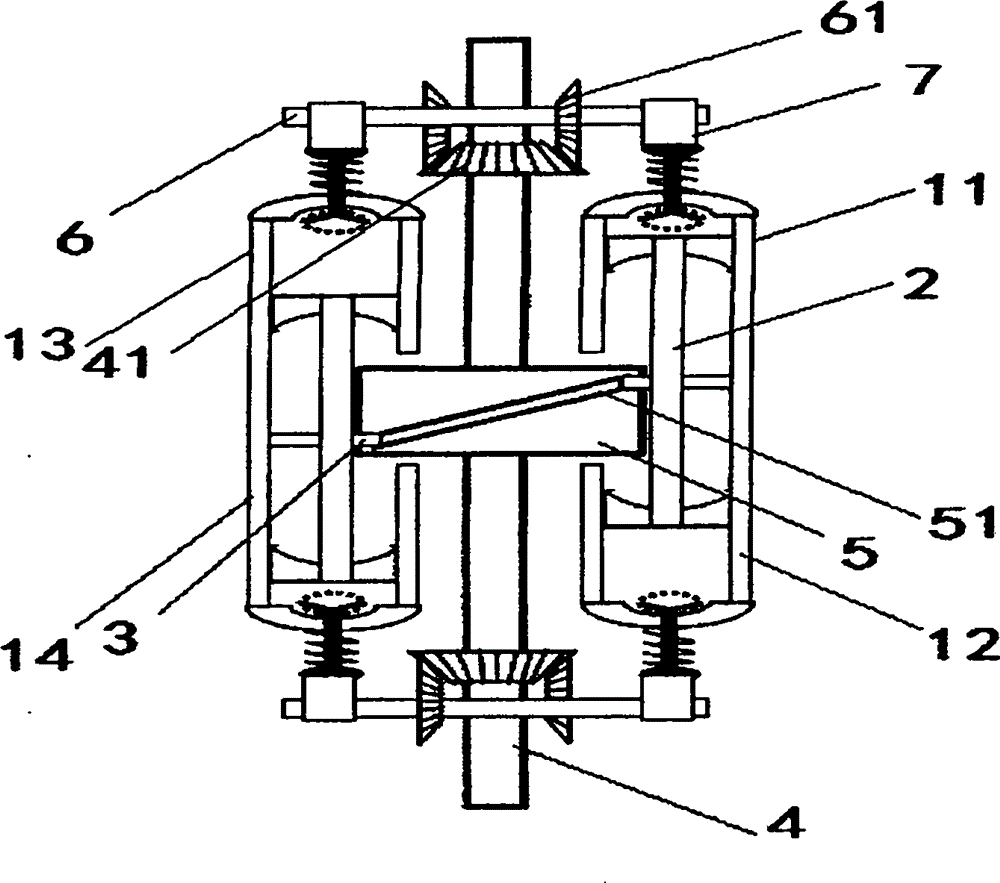

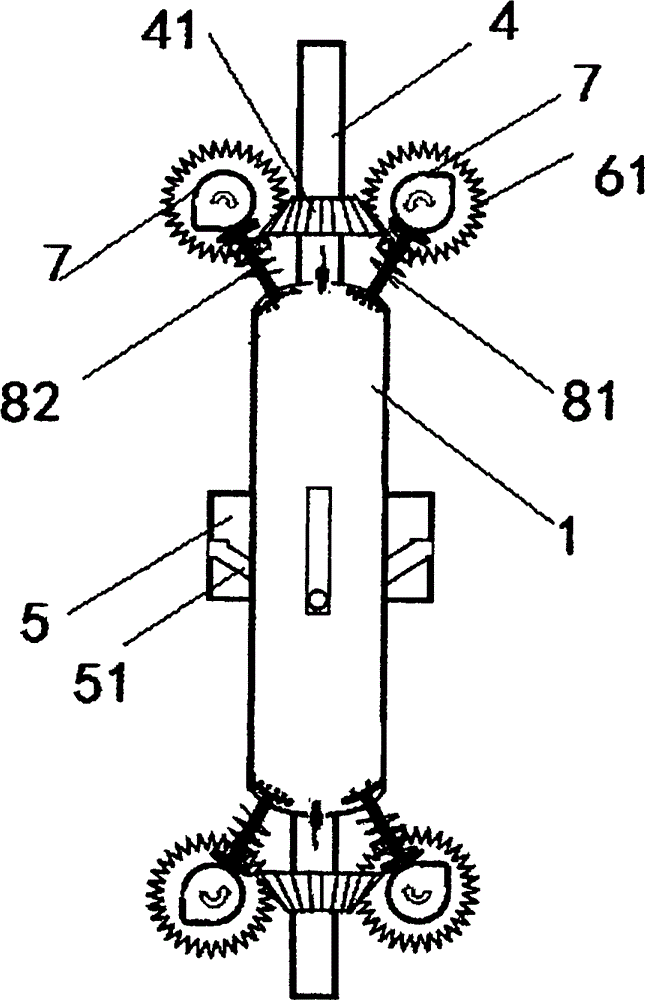

[0022] see figure 1 , 2 , a kind of automobile engine, comprises engine body and the gas distribution mechanism that is arranged on the body, certainly this automobile engine also includes fuel supply system, lubricating system, cooling system, ignition system and starting system etc., because these systems are not the present invention The focus of improvement is therefore not revealed in the figure 1 , and will not be described in detail here.

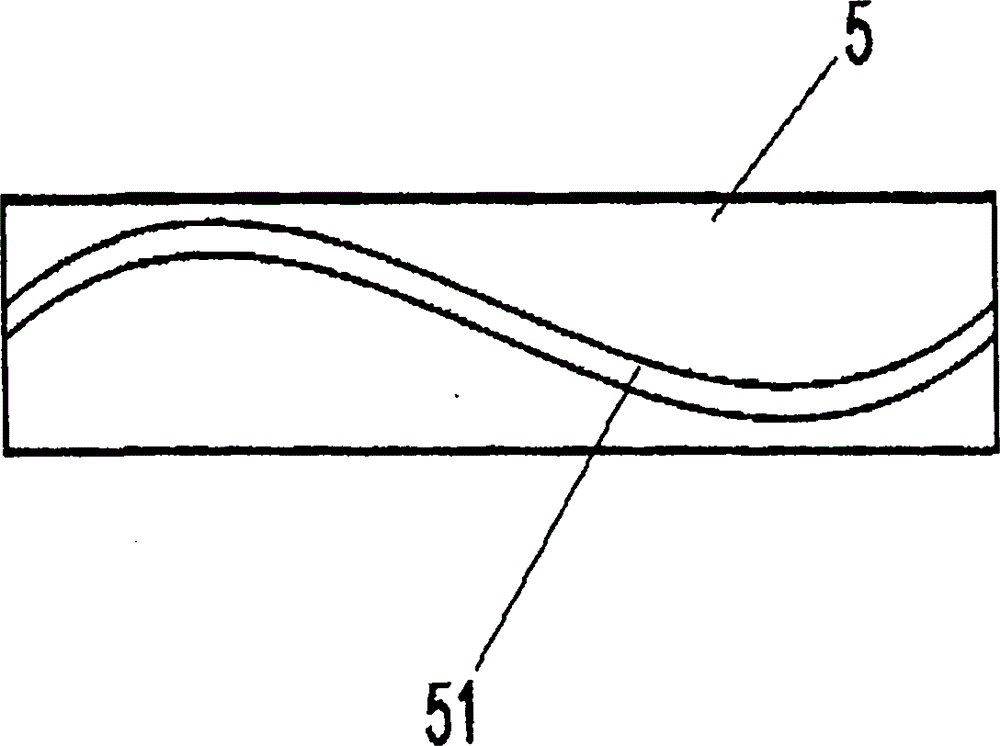

[0023] The improvement of the present invention is that the piston connecting rod of the cylinder 1 included in the engine block is connected with the rotor with a grooved slideway on the outer wall by means of a slider, so that the reciprocating linear motion of the cylinder piston is converted into the rotary motion of the rotor and the power output shaft .

[0024] In this embodiment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com